Method for recovering vanadium from vanadium-containing underflow slag

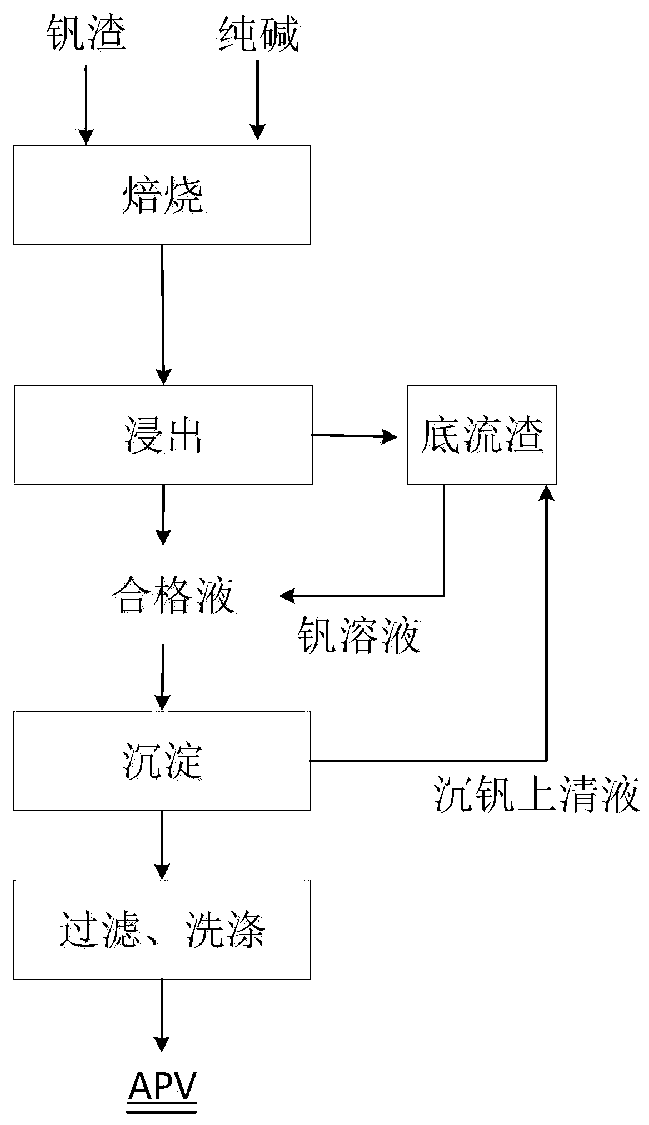

A technology for underflow slag and vanadium slag is applied in the field of recovering vanadium from vanadium-containing materials and recovering vanadium, which can solve the problems that have not yet been seen, and achieve the effects of high vanadium recovery rate, low material consumption and short process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 adopts the inventive method to reclaim vanadium from vanadium-containing underflow slag

[0039] Take 300mL of the supernatant at 65°C, add the underflow slag according to the liquid-solid ratio of 2:1, ml / g, stir at 90°C for 65min, filter, and send out the residue. : vanadium=1.5:1 (mass ratio) adds ammonium sulfate, adds sulfuric acid to adjust pH=2.2, heats 80min at 95 ℃, precipitates to obtain ammonium polyvanadate, filters, washes, and is calcined and melted after drying to obtain the vanadium pentoxide product, reaching 98-grade flake vanadium quality requirements, the recovery rate of vanadium in the whole process is 90%.

Embodiment 2

[0040] Embodiment 2 adopts the inventive method to reclaim vanadium from vanadium-containing underflow slag

[0041] Take 100mL of the supernatant at 80°C, add the underflow slag according to the liquid-solid ratio of 3:1, ml / g, stir at 80°C for 70min, filter, and send out the residue. : Vanadium=2:1 (mass ratio) adds ammonium sulfate, adds sulfuric acid to adjust pH=2.2, heats 90min at 90 ℃, precipitates to obtain ammonium polyvanadate, filters, washes, and calcines after drying to obtain vanadium pentoxide product, reaches 98 The quality requirements of vanadium powder are high, and the recovery rate of vanadium in the whole process is 92%.

Embodiment 3

[0042] Embodiment 3 adopts the inventive method to reclaim vanadium from vanadium-containing underflow slag

[0043] Take 400mL of the supernatant at 85°C, add the underflow slag according to the liquid-solid ratio of 3:1, ml / g, stir at 75°C for 80min, filter, and send out the residue. : Vanadium=3:1 (mass ratio) adds ammonium sulfate, adds sulfuric acid to adjust pH=2.4, heats 85min under 95 ℃, and precipitation obtains ammonium polyvanadate, filters, washes, and after drying, calcines and melts to obtain the vanadium pentoxide product, reaching The quality requirements of 99-grade flake vanadium, the recovery rate of vanadium in the whole process is 94.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com