Titanium alloy cast ingot and preparing method thereof

A technology for titanium alloy and ingot casting, applied in the field of titanium alloy ingot and its preparation, can solve the problems of uniformity of ingot composition and adverse effects of microstructure solidification, large smelting current, long feeding time, etc., and achieve chemical composition distribution. The effect of uniformity, reducing impurity content and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

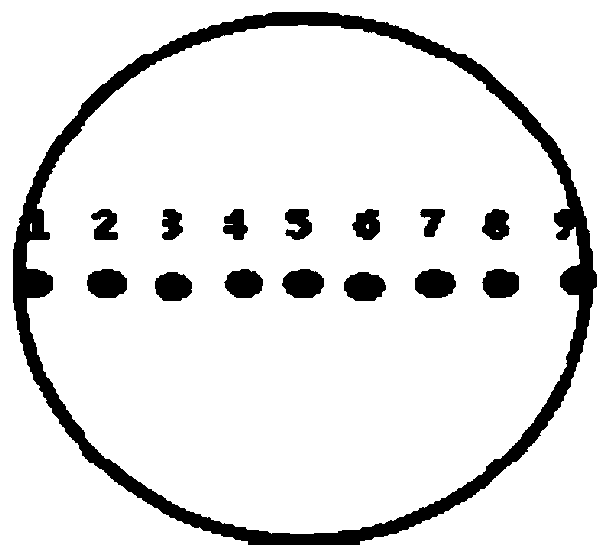

Image

Examples

preparation example Construction

[0031] A method for preparing a titanium alloy ingot according to an embodiment includes the following steps S1-S3.

[0032] S1. Dosing according to the ingredients required for the titanium alloy ingot to be prepared, mixing and pressing to form an electrode block.

[0033] In one embodiment, the total weight of the ingredients is 5000Kg-9400Kg.

[0034] In one embodiment, the specification of the electrode block is Φ480mm~Φ680mm, and the density of the electrode block is 3.4g / cm 3 ~3.6g / cm 3 .

[0035] Further, the shape of the electrode block is cylindrical.

[0036] Specifically, mix the titanium sponge and master alloy that meet the standards according to the ingredients required by the TA15 titanium alloy grade of GB / T3620.1. After the ingredients are fully mixed and uniform, press them into a specification of Φ480mm~Φ680mm and a density of 3.4g / cm 3 ~3.6g / cm 3 multiple electrode blocks.

[0037] S2. Stack and weld the plurality of electrode blocks to obtain consum...

Embodiment 1

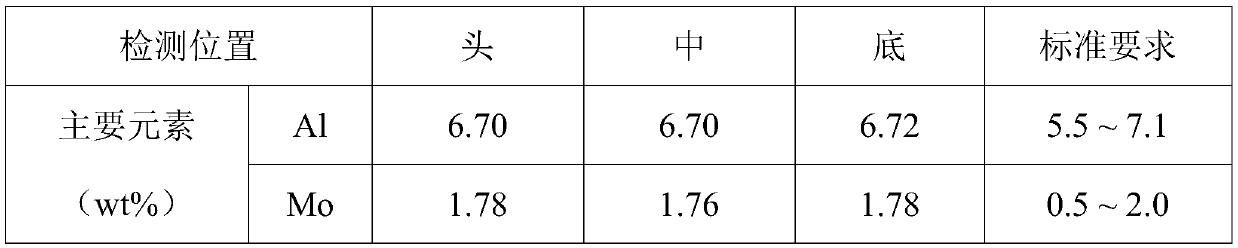

[0057] Example 1: Preparation of a TA15 titanium alloy ingot with a specification of Φ780mm

[0058] 1) Mix the titanium sponge and intermediate alloy that meet the standards according to the ingredients required by the TA15 titanium alloy grade of GB / T3620.1. After mixing the ingredients well, press them into a specification of Φ480mm and a density of 3.4g / cm 3 ~3.6g / cm 3 The circular electrode blocks are stacked into cylindrical strip electrodes.

[0059] 2) Weld the cylindrical long electrode in the vacuum plasma welding box with a welding torch with a water-cooled copper electrode tip to become a consumable electrode.

[0060] 3) The consumable electrode is smelted for the first time in a vacuum consumable electric arc furnace, using a crucible with a diameter of Φ580mm, the melting current is 14KA-18KA, the melting voltage is 28V-34V, the melting vacuum is ≤10Pa, and the arc is stable. The current is DC 6A~10A, and after smelting, it is cooled to about 350°C to obtain a...

Embodiment 2

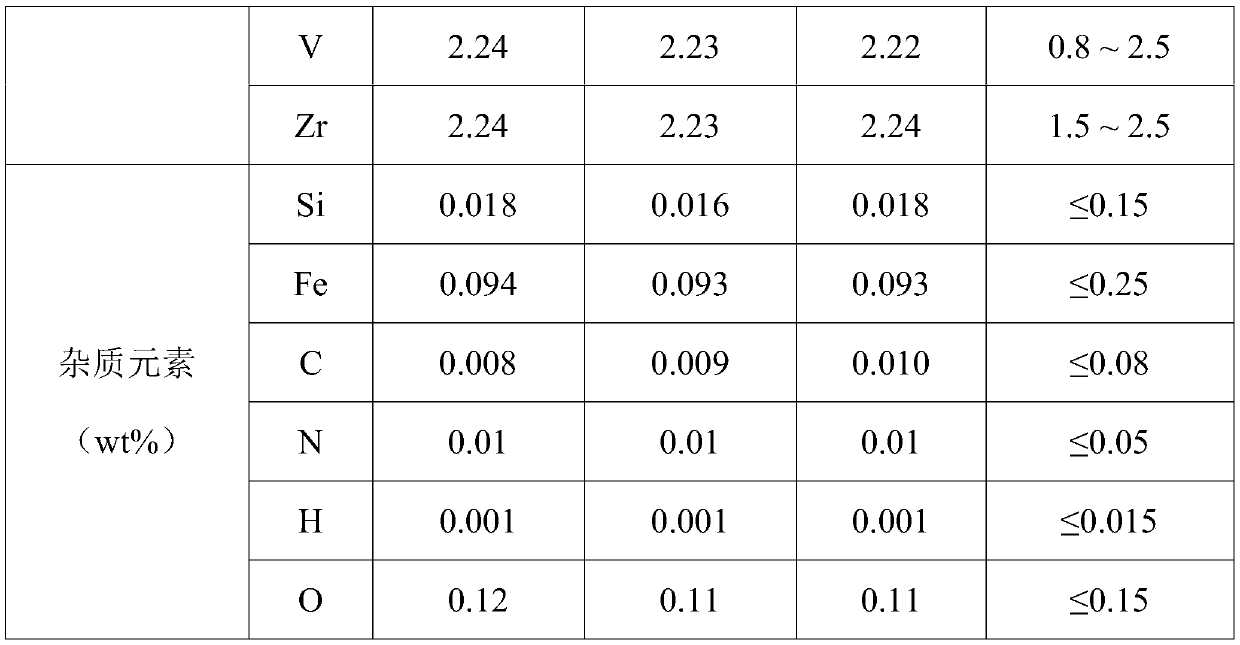

[0074] Embodiment 2: the preparation specification is the TC4 titanium alloy ingot of Φ980mm

[0075] 1) Mix the titanium sponge and master alloy that meet the standards according to the ingredients required by the TC4 titanium alloy grade in GB / T3620.1. After mixing the ingredients evenly, press them into a size of Φ680mm and a density of 3.4g / cm 3 ~3.6g / cm 3 The circular electrode blocks are stacked into cylindrical strip electrodes.

[0076] 2) Weld the cylindrical strip electrode in the vacuum plasma welding box with a welding torch with a water-cooled copper electrode tip to become a consumable electrode.

[0077] 3) The consumable electrode is smelted for the first time in a vacuum consumable electric arc furnace, using a crucible with a diameter of Φ780mm, a melting current of 18KA-21KA, a melting voltage of 32V-36V, a melting vacuum of ≤10Pa, and a stable arc current It is direct current 8A~12A, and after smelting, it is cooled to below 400°C to obtain a primary ingo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com