Thermo-mechanical treatment method for toughening high-performance wrought rare earth aluminum alloy

A deformation heat treatment, aluminum alloy technology, applied in the field of alloys, can solve the problems of low cost, high cost, poor toughness, etc., and achieve the effects of making up for the loss of alloy strength, increasing alloy elongation, and increasing recrystallization ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

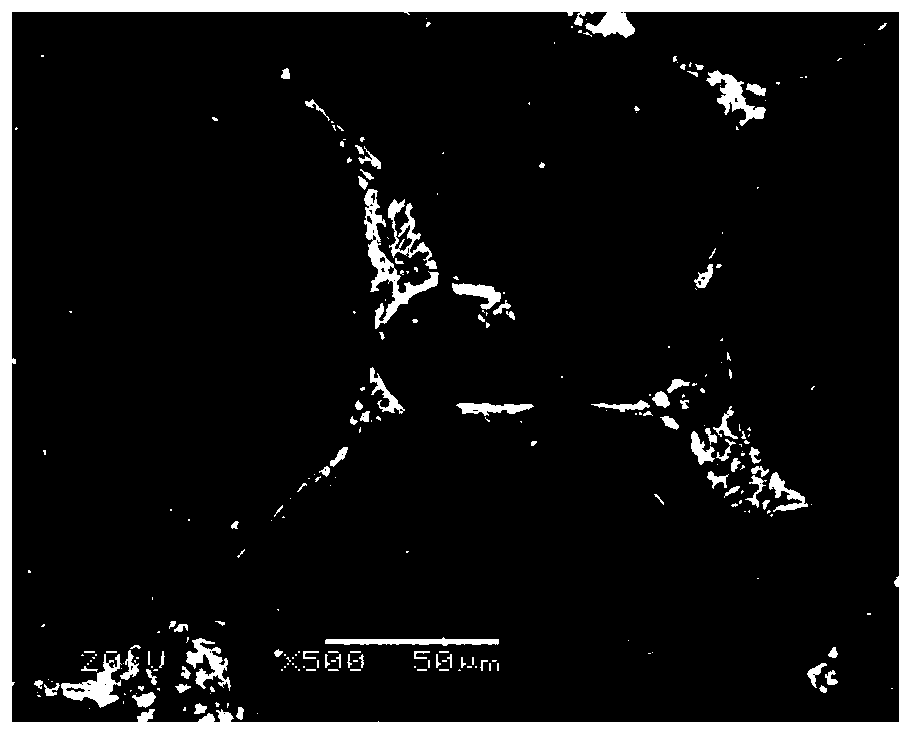

[0030] Select an ingot with the composition of Al-0.6Mg-0.7Si-0.2Er, cut it to make a cylindrical sample with a diameter of 100mm and a height of 500mm, and then perform homogenization treatment, that is, place the sample in a tubular heat treatment furnace In the furnace, the temperature was raised to 560°C with the furnace, kept for 10 hours, and then quenched in water at room temperature. Then put the homogenized cylindrical sample into a tubular heat treatment furnace, preheat it at 490°C for 4 hours, then place it in room temperature water for quenching, and cut the preheated cylindrical sample into a diameter of 97 mm and a height of After forming a cylindrical sample of 495mm, place it in the ingot barrel of a press and heat it for 8 minutes to an extrusion temperature of 510°C, perform hot extrusion deformation treatment at an extrusion speed of 1mm / s and an extrusion ratio of 10:1, and obtain a rod with a diameter of 31mm . The bar is processed into a tensile test ba...

Embodiment 2

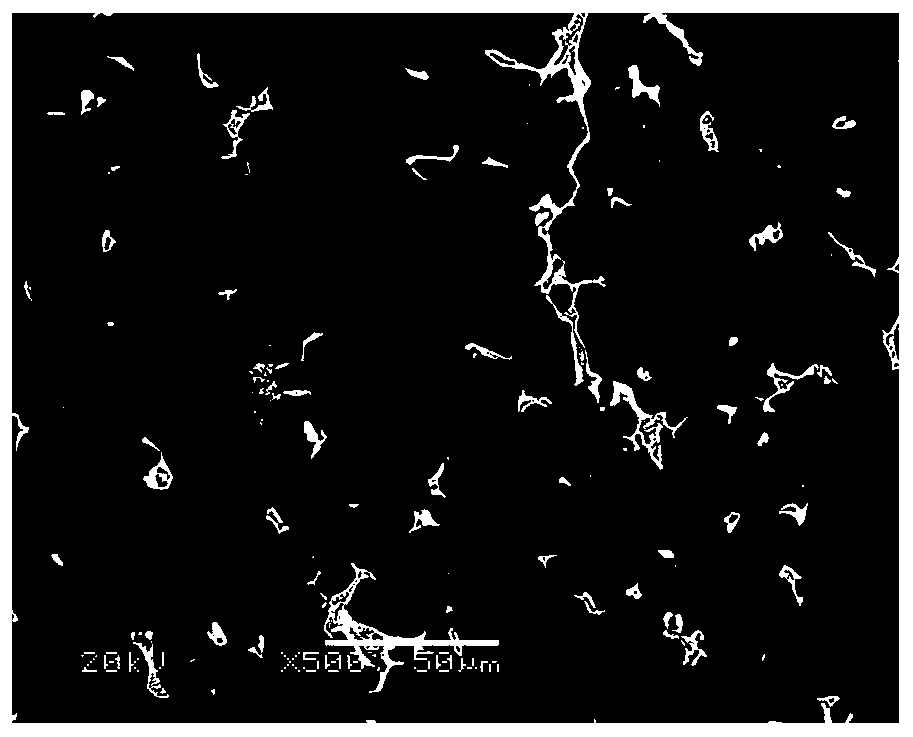

[0032] Select an ingot with the composition of Al-0.6Mg-0.7Si-0.3Er, cut it to make a cylindrical sample with a diameter of 100mm and a height of 500mm, and then perform homogenization treatment, that is, place the sample in a tubular heat treatment furnace In the furnace, the temperature was raised to 580°C with the furnace, kept for 8 hours, and then quenched in water at room temperature. Then put the homogenized cylindrical sample into a tubular heat treatment furnace, preheat it at 510°C for 2 hours, then place it in room temperature water for quenching, and cut the preheated cylindrical sample into a diameter of 97 mm and a height of After forming a cylindrical sample of 495mm, place it in the ingot barrel of a press and heat it for 8 minutes to an extrusion temperature of 510°C, then perform hot extrusion deformation treatment at an extrusion speed of 1mm / s and an extrusion ratio of 10:1 to obtain a rod with a diameter of 31mm material. The bar is processed into a tensi...

Embodiment 3

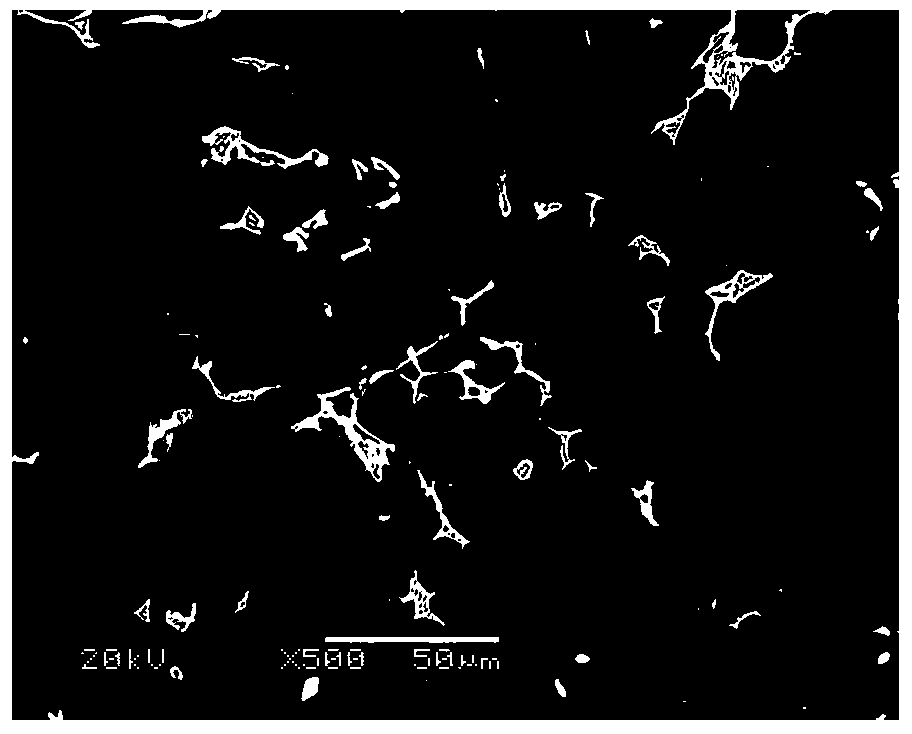

[0034] The steps are the same as in Example 1, except that the alloy is changed to Al-0.6Mg-0.7Si-0.4Er alloy. Its yield strength is 376MPa, tensile strength is 440MPa, and elongation is 10.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com