Chain shaft and shaft sleeve structure of automatic woodworking feeder

An automatic feeding and chain shaft technology, applied in the direction of shafts and bearings, rolling contact bearings, rotating bearings, etc., can solve the problems of little improvement, easy wear of chain shafts and bushings, wear failure, etc., to reduce daily Maintenance work, ensuring sufficient lubrication, and reducing the effect of friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

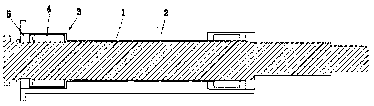

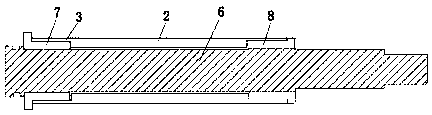

[0017] Example 1, see image 3 , image 3 It is the chain shaft and shaft sleeve structure in the prior art, including carbon steel chain shaft 6, first shaft sleeve 7, second shaft sleeve 8, installation sleeve 2 and groove 3, carbon steel chain shaft 6 is installed on the side of installation sleeve 2 Inside, two grooves 3 are provided on the left and right sides of the inner wall of the installation sleeve 2, the first sleeve 7 is installed in the groove 3 on the left side, and the second sleeve 8 is installed in the groove 3 on the right side. middle. The carbon steel chain shaft 6, the first shaft sleeve 7, and the second shaft sleeve 8 belong to the sliding friction of surface contact. In the environment of unenclosed liquid lubrication, the friction coefficient is high and the wear is fast, because the carbon steel chain shaft 6 and the shaft sleeve cooperate. There is a gap between them, and the butter will liquefy and lose from the gap at high operating temperatures...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com