Method for separating scandium and uranium from scandium-containing uranium ore

A technology for uranium ore and tailings, applied in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of complex process, low recovery rate, waste of raw ore, etc., achieve high enrichment ratio, simple operation, and separation high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

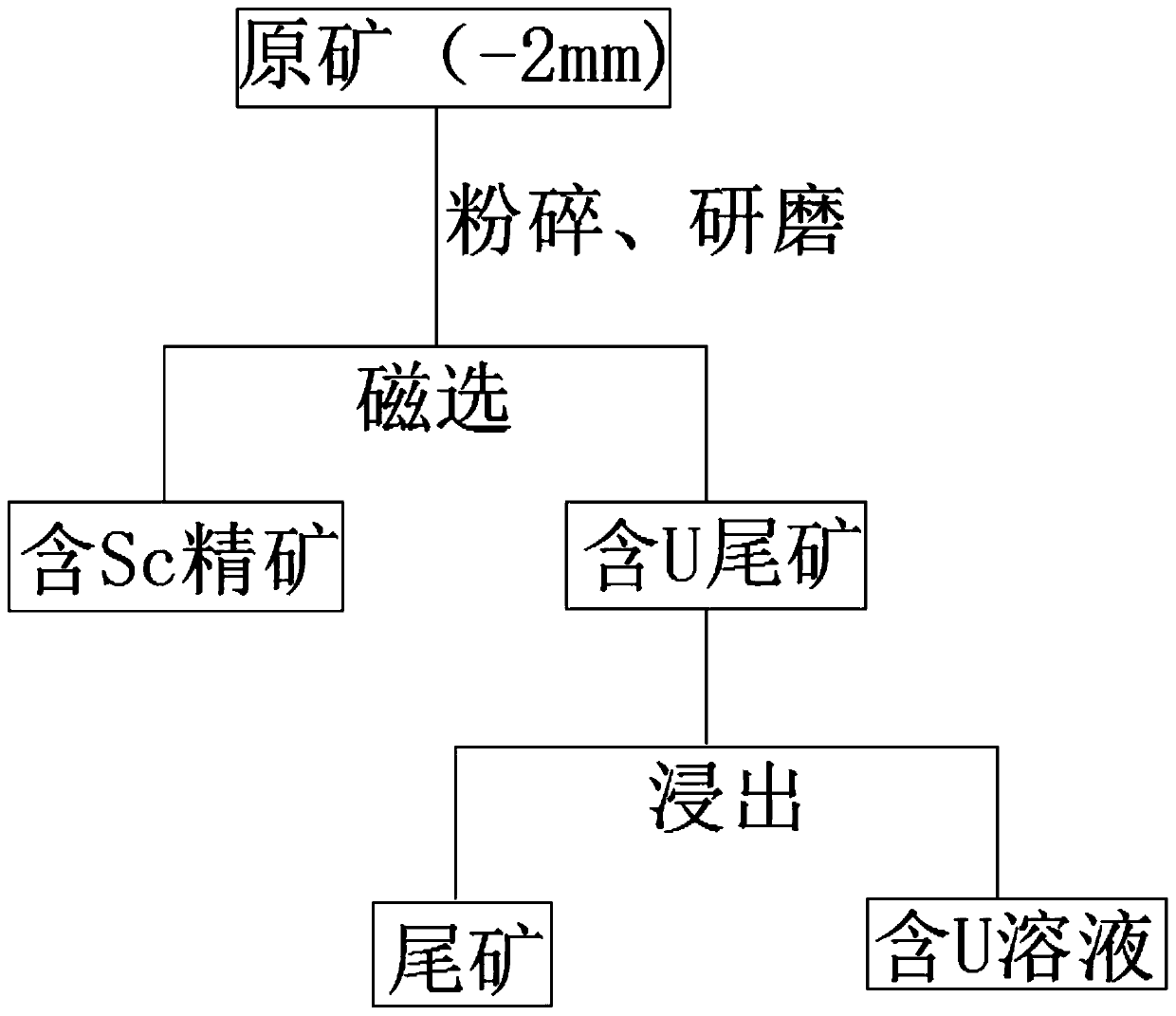

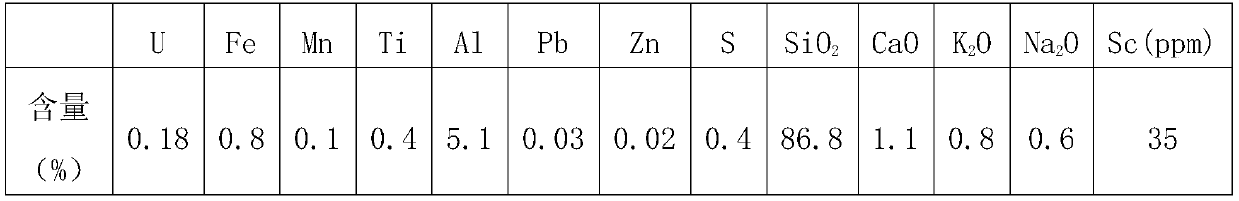

[0032] A method for separating scandium and uranium from scandium-containing uranium ore, the specific steps are:

[0033] S1: Use a crusher to crush and grind the raw ore with a grain size of -2mm to -200 mesh, accounting for 65-70%;

[0034] S2: adding the ground particles in step S1 to a strong magnetic separator for magnetic separation, the induction intensity of the strong magnetic flotation machine is 1.2T, to obtain scandium-containing concentrate and uranium-containing tailings, and collect scandium-containing concentrate;

[0035] S3: leaching the uranium-containing tailings in step S2 with a concentrated acid with pH=3 to obtain a uranium-rich acid solution and tailings, filter, separate the uranium-containing acid solution from the tailings, and perform the following steps on the obtained uranium-containing acid solution Process and collect uranium in one step.

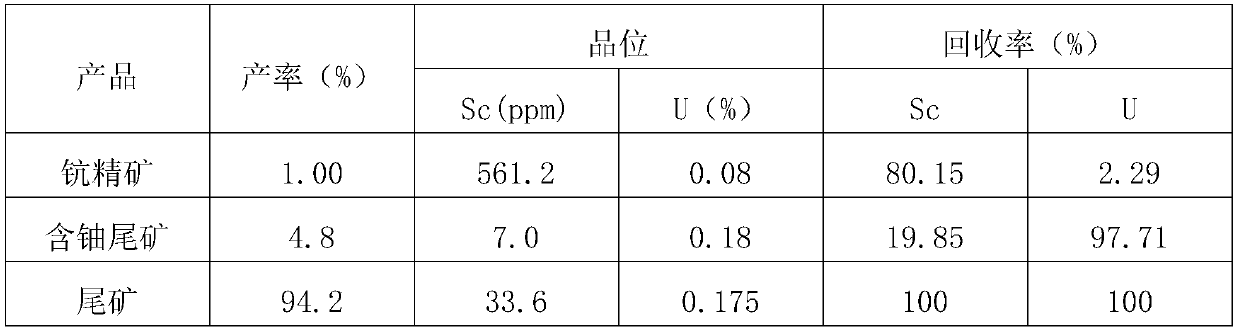

[0036] The above-mentioned scandium-containing concentrate and uranium-containing acid solution were te...

Embodiment 2

[0041] A method for separating scandium and uranium from scandium-containing uranium ore, comprising the following steps:

[0042] S1: Use a crusher to crush and grind the raw ore with a grain size of -2mm to -200 mesh, accounting for 65-70%;

[0043] S2: Put the particles ground in step S1 into a strong magnetic separator for magnetic separation, the induction intensity of the strong magnetic flotation machine is 1.5T, obtain scandium-containing concentrate and uranium-containing tailings, and collect scandium-containing concentrate;

[0044] S3: leaching the uranium-containing tailings in step S2 with sulfuric acid at pH=1 to obtain a uranium-rich acid solution and tailings, filter, separate the uranium-containing acid solution from the tailings, and proceed to the next step with the obtained uranium-containing acid solution Process and collect uranium.

[0045] The grade of scandium in concentrate containing scandium is 560.5ppm, the recovery rate is 75.9%; the recovery ra...

Embodiment 3

[0047] A method for separating scandium and uranium from scandium-containing uranium ore, comprising the following steps:

[0048] S1: Use a crusher to crush and grind the raw ore with a grain size of -2mm to -200 mesh, accounting for 65-70%;

[0049] S2: Put the particles ground in step S1 into a strong magnetic separator for magnetic separation. The induction intensity of the strong magnetic flotation machine is 1.3T to obtain scandium-containing concentrates and uranium-containing tailings, and collect scandium-containing concentrates;

[0050] S3: leaching the uranium-containing tailings in step S2 with a concentrated acid with pH=3 to obtain a uranium-rich acid solution and tailings, filter, separate the uranium-containing acid solution from the tailings, and perform the following steps on the obtained uranium-containing acid solution Process and collect uranium in one step.

[0051] The grade of scandium in the concentrate containing scandium is 559.8ppm, the recovery r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com