A kind of blast furnace seam filling material and preparation method thereof

A technology for filling joints and blast furnaces, which is applied in the field of metallurgical refractories, can solve problems such as unfavorable blast furnace production and longevity, easy formation of voids, redness of furnace shells, etc., and achieves significant blocking effect, increase production, and prevent gas leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

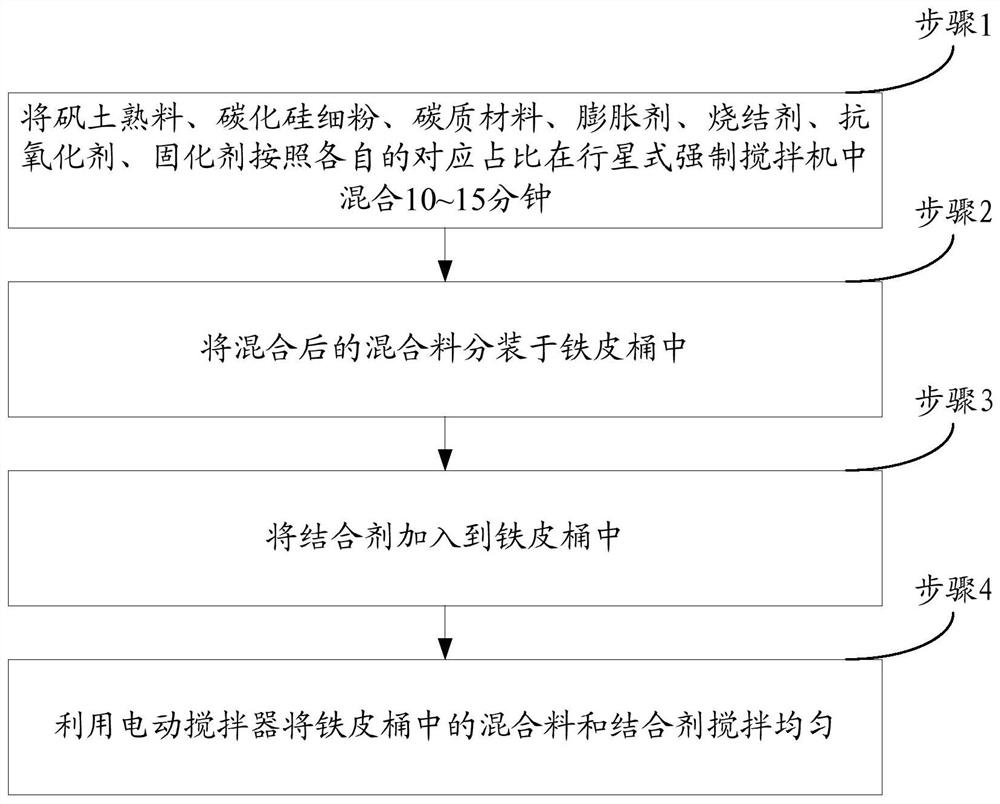

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the purpose, technical solution and advantages of the present invention more clear and clear, the following reference to the attached figures and implementing examples, further explaining the present invention.

[0048] Examples of the present invention provide a blast furnace irrigation material, according to the quality percentage of the quality, the composition of the sewing of the blast furnace includes: 35 % to 56 % of alum soil clinker, 0 % to 12 % silicon carbide fine powder, 0 % 0 % ~ 18 % carbon material, 4 % to 8 % expansion agent, 5 % to 8 % sintering agent, 0 % to 3 % antioxidant, 21.6 % to 27 % binding agent, 0.6 % to 1.5 % Hardener.

[0049] In the embodiments of the present invention, the percentage of each component is the percentage of quality, that is, the quality ratio, and the percentage of the explanations of the embodiments of the present invention represents the quality percentage.

[0050] In the embodiment of the present invention, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com