Optical anti-counterfeiting material and preparation method thereof

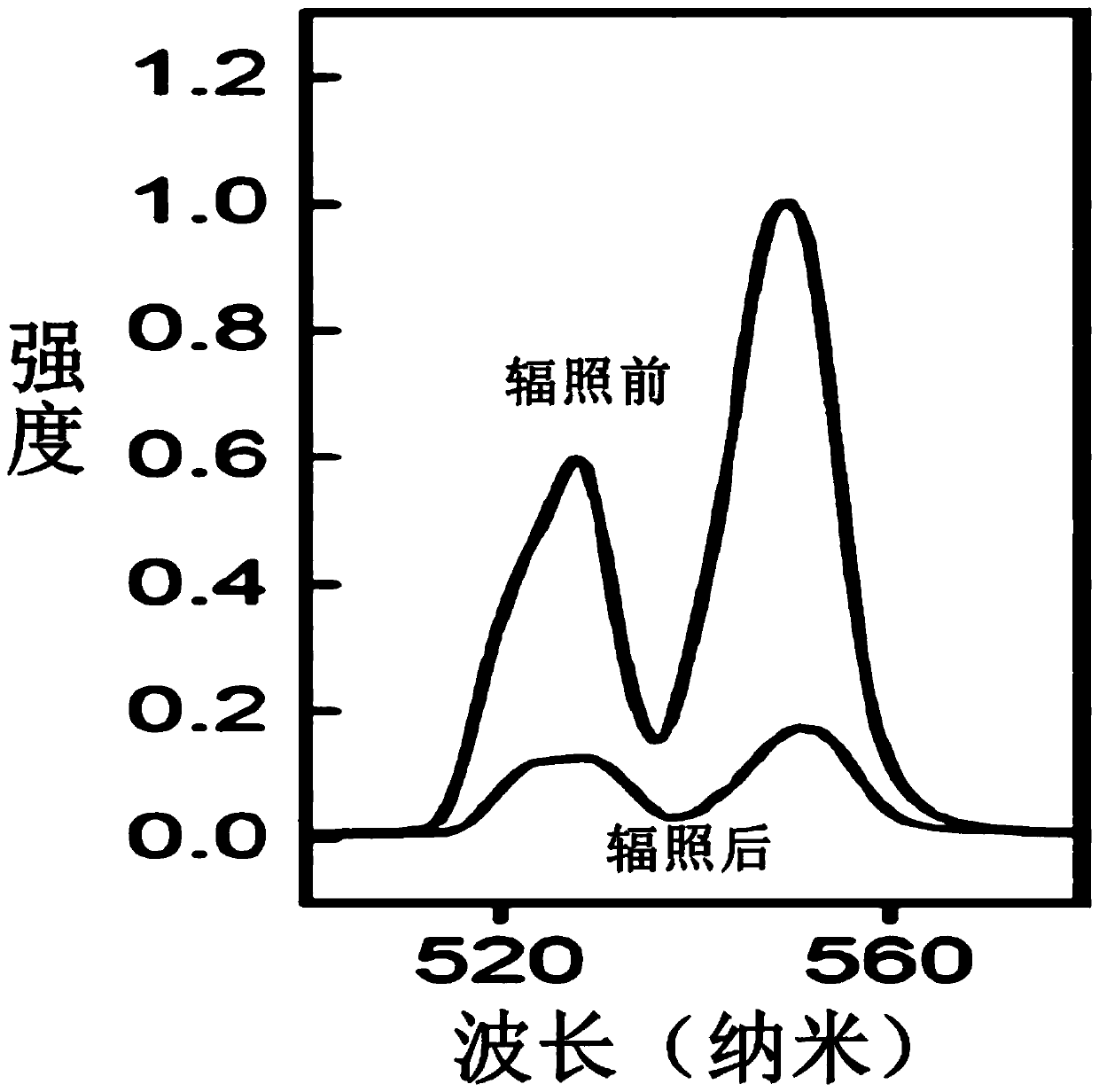

An optical anti-counterfeiting and raw material technology, applied in the field of optical anti-counterfeiting materials and their preparation, can solve the problems of difficult multi-mode fluorescent anti-counterfeiting technology, and achieve the effects of low cost, good stability and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of the optical anti-counterfeiting material of this embodiment comprises the following steps:

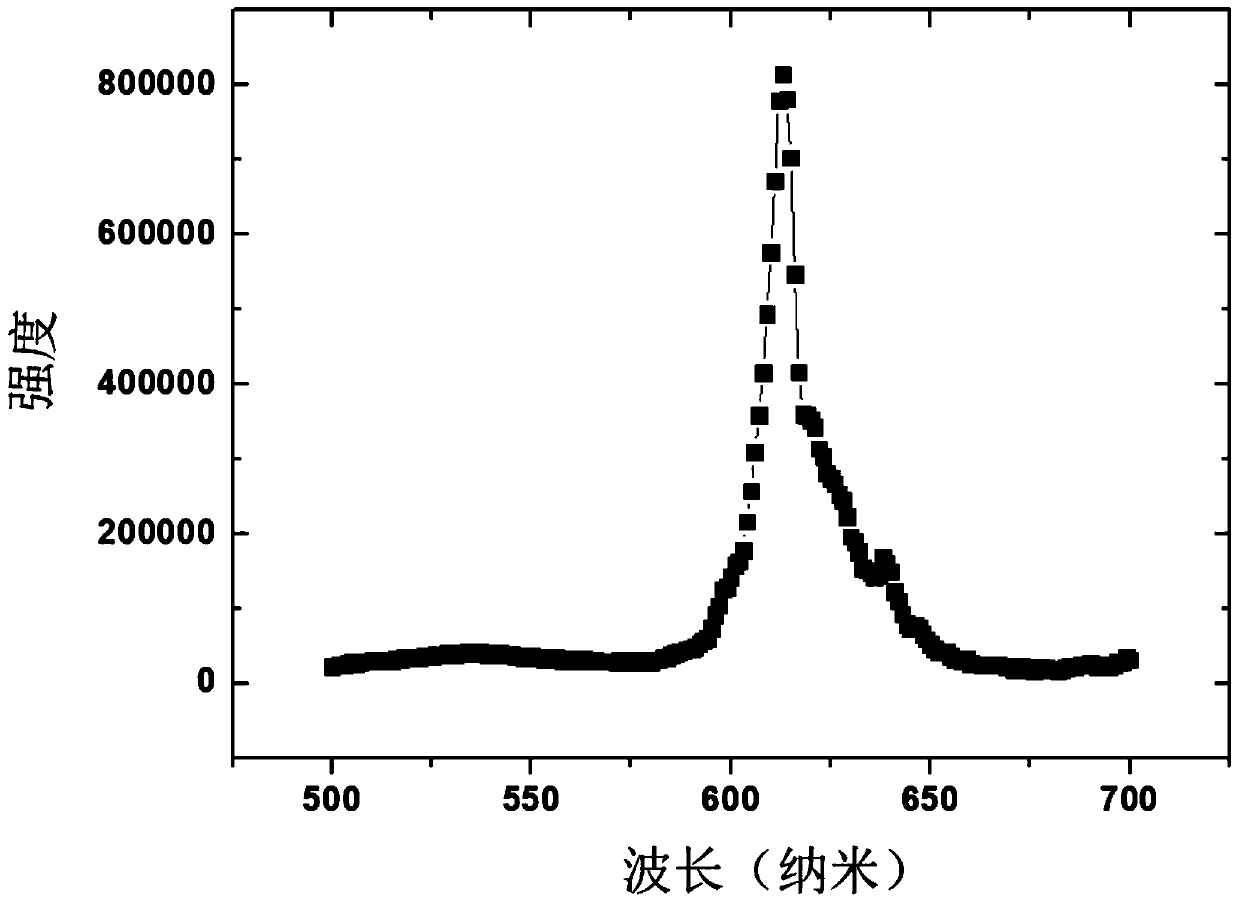

[0032] 1. Preparation of Sr 1.995 Er 0.005 SnO 4 Material: SrCO with a purity of 99.5% 3 , 99.9% SnO 2 , 99.9% Er 2 o 3 As raw material, according to Sr 1.995 Er 0.005 SnO 4 The metering ratio is weighed, put into a ball mill tank and mixed for ball milling, ball milling conditions: the volume ratio of the volume of raw materials, agate ball volume, and ball milling medium absolute ethanol is equal to 1:1:1.5, and it is ball milled for 12 hours, and the raw materials after ball milling are placed Bake in an oven at 80°C for 4 hours. Afterwards, use a tablet machine to press the dried raw materials into raw material embryos with a diameter of 40mm, and then put the pressed green embryos into a KSL-1700X box furnace for pre-calcination. The pre-calcination condition is 800°C After 1 hour, crush the pre-fired block sample, grind it into a powder, sieve ...

Embodiment 2

[0040] Basically the same as Embodiment 1, the difference is that step 3 of this embodiment is:

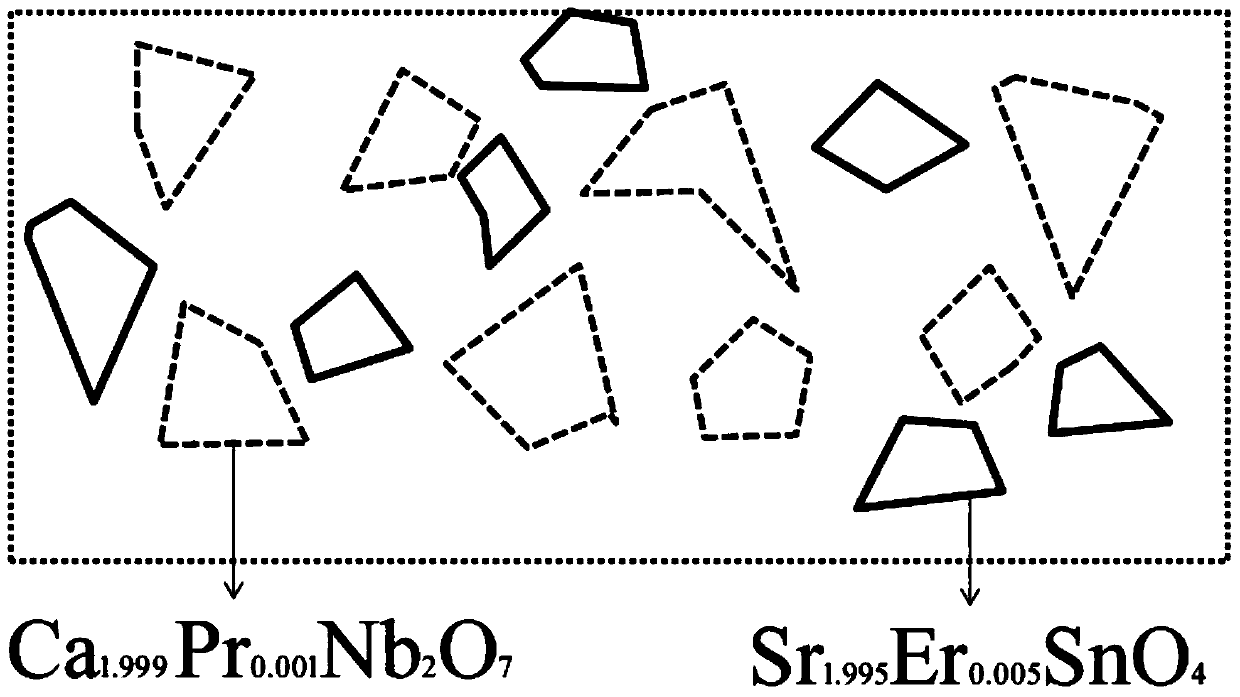

[0041] The prepared Sr 1.995 Er 0.005 SnO 4 Material and Ca 1.999 PR 0.001 Nb 2 o 7 The materials are crushed, then weighed and mixed according to the mass ratio of 1:1 to obtain the raw materials, and then the raw materials are put into a ball mill tank and mixed for ball milling. Ball milling conditions: the volume of raw materials, the volume of agate balls, and the volume ratio of absolute ethanol as the ball milling medium Equal to 1:1:1.5, ball mill it for 12 hours, put the raw material after ball milling into an oven and bake at 80°C for 4 hours to get mixed solid powder; mix the mixed solid powder and polydimethylsiloxane solution according to the ratio of 4:6 The mass ratio is mixed to obtain a mixture solution, and then the mixture solution is cast on a glass substrate by a tape casting machine, and finally cured at 80°C to form a film, and finally a composite flex...

Embodiment 3

[0044] Basically the same as Embodiment 1, the difference is that step 3 of this embodiment is:

[0045] The prepared Sr 1.995 Er 0.005 SnO 4 Material and Ca 1.999 PR 0.001 Nb 2 o 7 The materials are crushed, then weighed and mixed according to the mass ratio of 1:1 to obtain the raw materials, and then the raw materials are put into a ball mill tank and mixed for ball milling. Ball milling conditions: the volume of raw materials, the volume of agate balls, and the volume ratio of absolute ethanol as the ball milling medium Equal to 1:1:1.5, ball mill it for 12 hours, put the raw material after ball milling into an oven and bake at 80°C for 4 hours to obtain mixed solid powder; mix the mixed solid powder and polydimethylsiloxane solution according to the ratio of 2:8 The mass ratio is mixed to obtain a mixture solution, and then the mixture solution is cast onto a glass substrate by a tape casting machine, and finally cured at 80°C to form a film, and finally a composite f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Folding angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com