Polypropylene spunbond nonwoven fabric and preparation process for improving softness of polypropylene spunbond nonwoven fabric

A spun-bonded non-woven fabric and preparation technology, which is applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve the problems of water absorption and heat dissipation performance, the performance of preventing rewetting, and the reduction of overall strength, and achieve shrinkage. Low, improve the performance of preventing rewetting, and improve the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

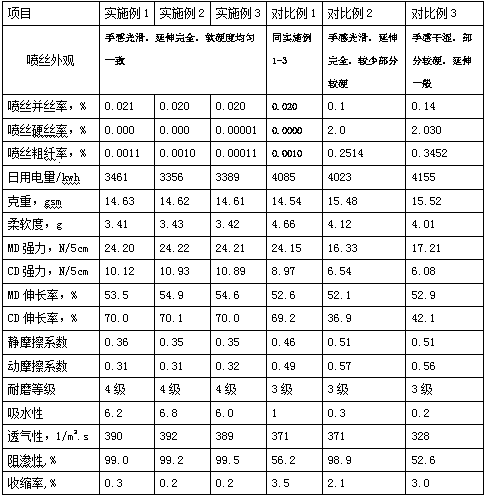

Examples

Embodiment 1

[0031] Example 1 A preparation process for improving the softness of polypropylene spunbond nonwoven fabric

[0032] A kind of preparation technology that improves the softness of polypropylene spunbonded nonwoven fabric of the present invention, comprises the following steps:

[0033] (1) Preprocessing:

[0034] Add PP material, melt-blown material, functional masterbatch and white masterbatch into the mixing device, after automatic feeding, melt extrusion and melt filtration, then the raw materials are melt-measured according to requirements.

[0035] Wherein, the addition of described meltblown material accounts for 3% of total raw material;

[0036] The meltblown material is a high melt index PP meltblown material with a melt index of 800g / 10min.

[0037] (2) Die Spinning:

[0038] Take the raw materials after melt metering and carry out die spinning;

[0039] Die spinning process parameters are as follows:

[0040] Bellows pressure is 2900pa;

[0041] Fan speed rati...

Embodiment 2

[0053] Embodiment 2 A kind of preparation technology that improves the softness of polypropylene spunbonded nonwoven fabric

[0054] A kind of preparation technology that improves the softness of polypropylene spunbonded nonwoven fabric of the present invention, comprises the following steps:

[0055] (1) Pretreatment: Add PP material, melt-blown material, functional masterbatch and white masterbatch to the mixing device, after automatic feeding, melt extrusion and melt filtration, the raw materials are then melt-measured according to requirements.

[0056] Wherein, the addition of described meltblown material accounts for 5% of total raw material;

[0057] The meltblown material is a high melt index PP meltblown material with a melt index of 1200g / 10min.

[0058] (2) Die Spinning:

[0059] Take the raw materials after melt metering and carry out die spinning;

[0060] Die spinning process parameters are as follows:

[0061] The bellows pressure is 3300pa; the fan speed ra...

Embodiment 3

[0069] Embodiment 3 A kind of preparation technology that improves the softness of polypropylene spunbonded nonwoven fabric

[0070] A kind of preparation technology that improves the softness of polypropylene spunbonded nonwoven fabric of the present invention, comprises the following steps:

[0071] (1) Pretreatment: Add PP material, melt-blown material, functional masterbatch and white masterbatch to the mixing device, after automatic feeding, melt extrusion and melt filtration, the raw materials are then melt-measured according to requirements.

[0072] Wherein, the addition of described meltblown material accounts for 10% of total raw material;

[0073] The meltblown material is a high melt index PP meltblown material with a melt index of 1500g / 10min.

[0074] (2) Die Spinning:

[0075] Take the raw materials after melt metering and carry out die spinning;

[0076] Die spinning process parameters are as follows:

[0077] The bellows pressure is 4000pa; the fan speed r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softness | aaaaa | aaaaa |

| Powerful | aaaaa | aaaaa |

| Powerful | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com