Double-fire-hole characteristic combustor formed by vertically stacking thin pipe annular row sets

A thin tube and fire hole technology, which is applied in the field of dual fire hole characteristic burners, can solve the problems of high fire hole porosity, increased residence time, a large amount of waste materials, etc., and achieves the effect of excellent combustion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

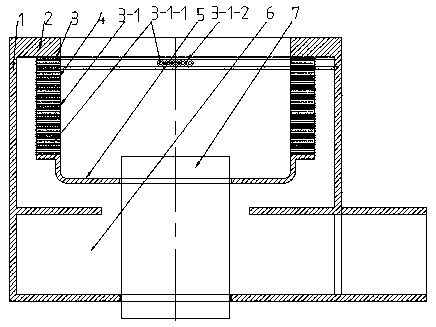

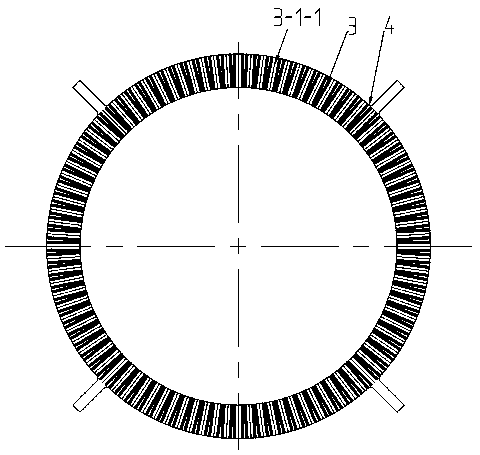

[0012] Combine below figure 1 and figure 2 To illustrate the embodiment of the present invention, the present invention includes a distribution chamber outside cylinder 1, a distribution chamber gland 2, a distribution chamber 1-1, a thin tube 3, an annular partition 4, a fire distributor 3-1, a combustion chamber 5-1, and a combustion chamber bottom plate 5. Mixer 6. Ignition and flameout protection device 7.

[0013] It is characterized in that thin tubes 2 are evenly distributed on the surface of one side of the annular partition plate 4, and the outlet of the thin tubes 3 faces the combustion chamber 5-1, the inlet of the thin tubes 3 faces the distribution chamber 1-1, and a plurality of thin tubes 3 are distributed. The annular baffles 4 are stacked together to form the fire distributor 3-1 of the burner, and the triangular-shaped holes formed between the outer walls of the adjacent two narrow tubes 3 and the surface of the annular baffle 4 are auxiliary fire holes 3-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com