A natural gas assisted flame treatment burner

A flame treatment and burner technology, which is applied in the field of natural gas assisted flame treatment burners, can solve the problems of potential safety hazards, insufficient fuel, low flame temperature, etc., and achieve the effects of saving installation space, high heating efficiency and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

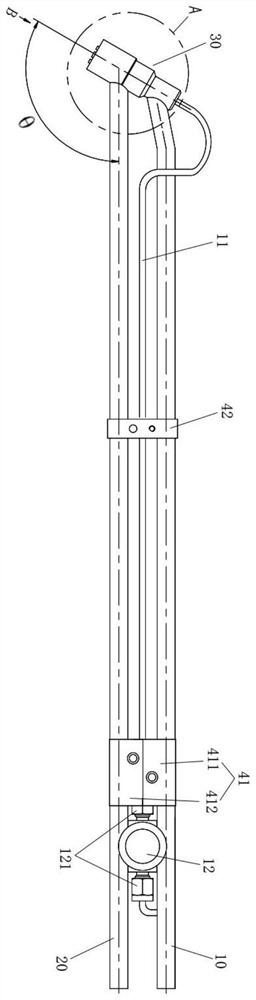

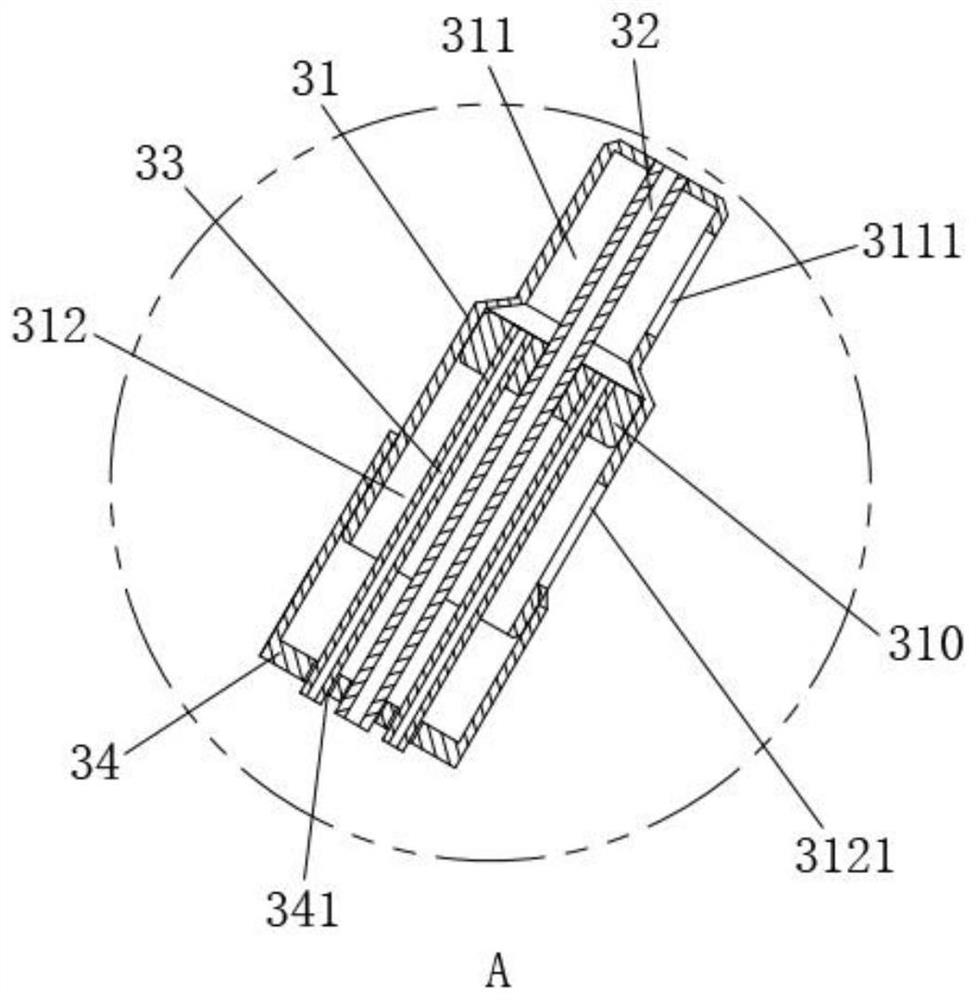

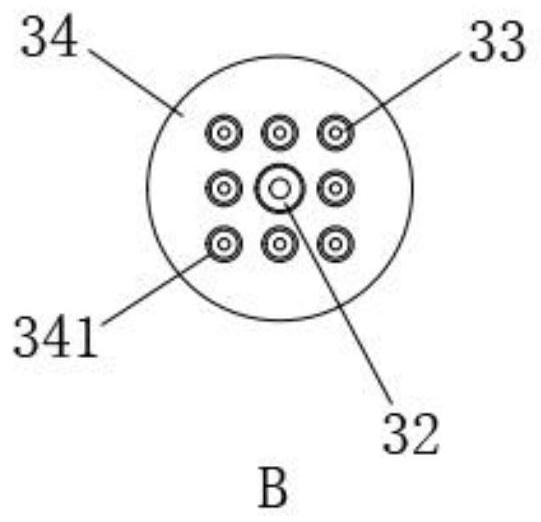

[0020] Such as figure 1 As shown, a natural gas assisted flame treatment burner of the present invention includes an oxygen pipe 10 , an oxygen branch pipe 11 , a needle valve 12 , a natural gas pipe 20 and a combustion assembly 30 . Both the oxygen pipe 10 and the natural gas pipe 20 are connected to the combustion assembly 30, and respectively deliver oxygen and natural gas to the combustion assembly 30, and the gas delivered by the oxygen pipe 10 and the natural gas pipe 20 is in the The outlet of the combustion assembly 30 is mixed, the oxygen branch pipe 11 is connected to the oxygen pipe 10, and the oxygen branch pipe 11 is connected to the combustion assembly 30 at the same time, and oxygen is delivered to the middle of the outlet of the combustion assembly 30. The needle valve 12 is installed on the oxygen branch pipe 11, and by adjusting the needle valve 12, the oxygen flow in the middle of the outlet of the combustion assembly 30 is adjusted, thereby adjusting the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com