BGA tin-lead solder ball solidification process simulation method based on cellular automaton

A cellular automata and process simulation technology, applied in the direction of design optimization/simulation, which can solve the problems of metal opacity, lack of direct and effective methods for experimental research, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

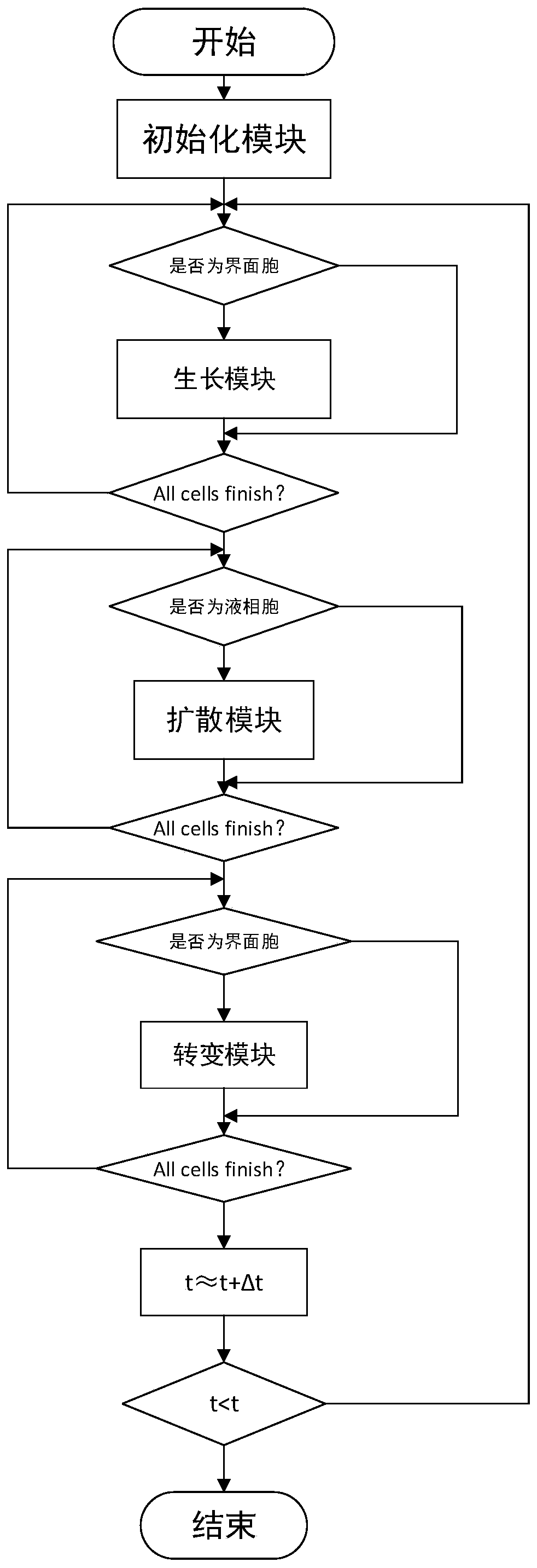

[0079] A method for simulating the solidification process of BGA tin-lead solder balls based on cellular automata figure 1 As shown, the method of this embodiment is as follows.

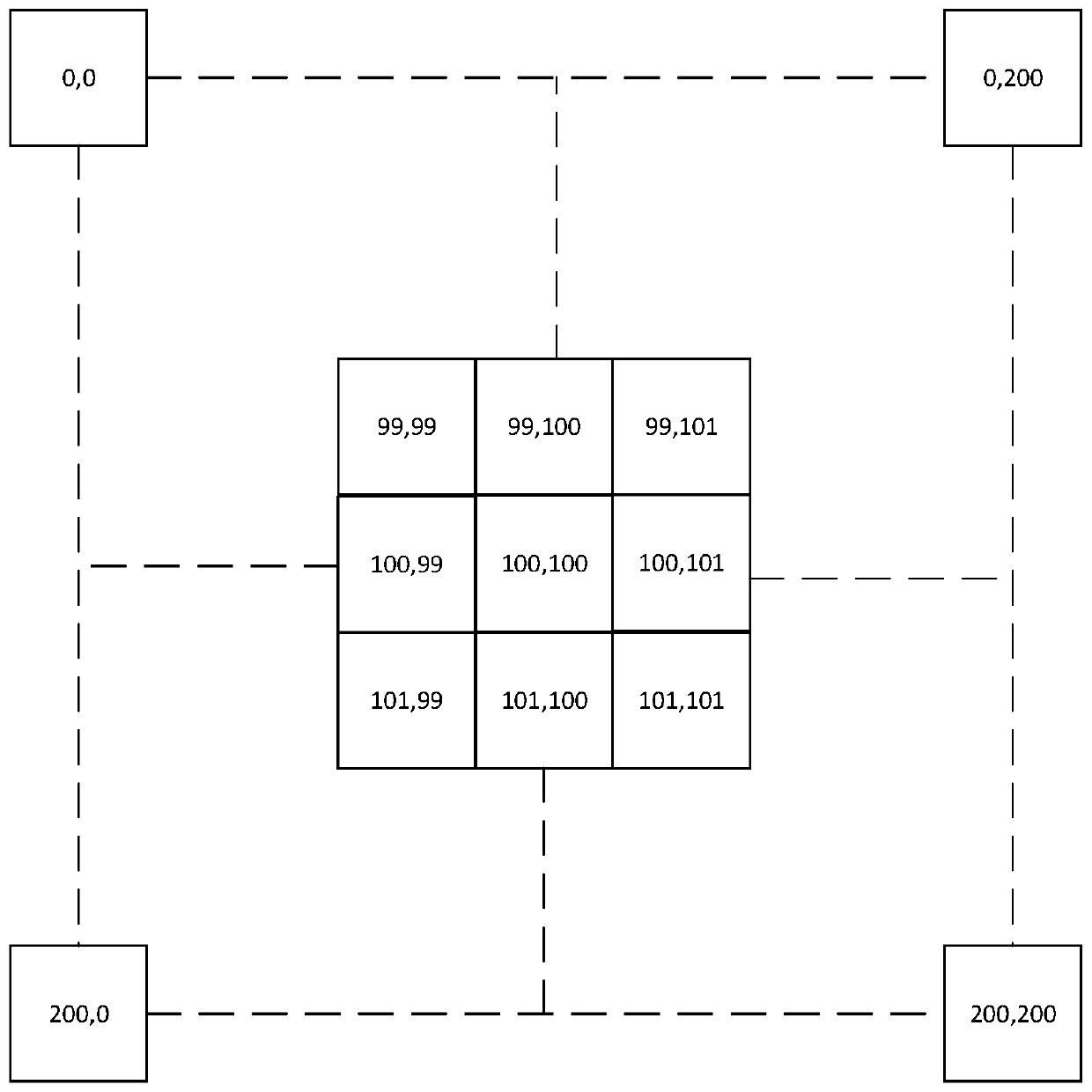

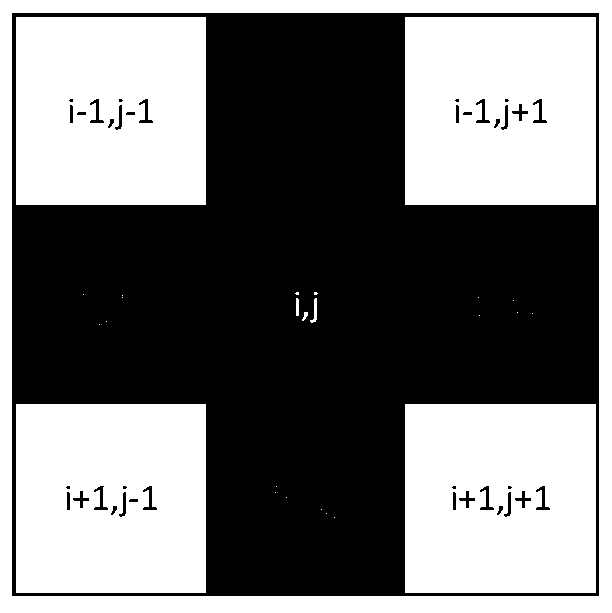

[0080] Step 1: Obtain the thermodynamic parameters, solute diffusion parameters, and nucleation parameters required for calculation from experiments and literature related to dendrite growth. The thermodynamic parameters include thermal subcooling, alloy melting point, cell temperature, latent heat, specific heat capacity of alloy materials, Thermal diffusivity, solute diffus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com