Circuit breaker and gas insulated switchgear using the circuit breaker

A circuit breaker and insulating frame technology, which is applied in the field of power distribution, can solve problems such as cumbersome assembly procedures, and achieve the effects of convenient processing and production, uniform potential, and reduced overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

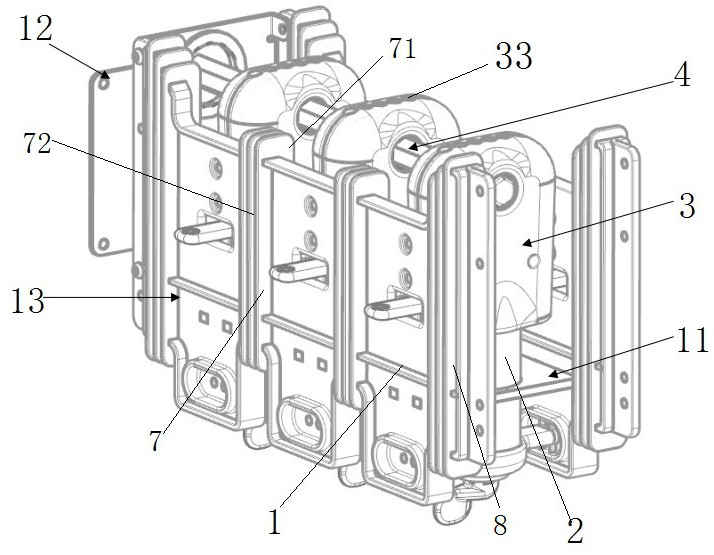

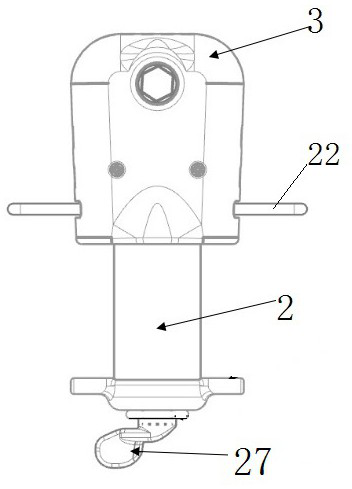

Embodiment 1

[0093] like Figure 7 As shown, the circuit breaker 100 in this embodiment can be Figure 7 As shown, in the gas box 400 installed in the gas insulated switchgear, such as a ring cabinet, the circuit breaker 100 is driven by the actuation mechanism 101 mounted outside the air box 400, and realizes the separation brake operation, and each of the circuit breakers. When the outer line of the arc chamber is electrically connected to the corresponding input line sleeve 300, when the wiring sleeve 300 is electrically connected to the external cable, the wiring sleeve 300 is connected to the external cable, and the ring cabinet is connected to the grid. Normal work of the NIC.

[0094] In this embodiment, in order to conform to the environmental protection, the gas box 400 is charged into the environmentally friendly gas, and the dry air or nitrogen can be filled to meet the environmental requirements.

[0095] Because the environmentally friendly gas is slightly poor than the sulfur insul...

Embodiment 2

[0131] It is mainly in the first embodiment in the first embodiment, and the shield is formed in each of the top ends of each extinguishing chamber, and the action of shielding agencies, in the present embodiment, can also save shielding The cover, at this time, it is necessary to increase the size of the inner protruding portion of the phase insulating umbrella dress to meet the corresponding insulating interval requirements.

[0132] Of course, at this time, it is also possible to refer to the prior art, and the phase insulation structure is arranged on the insulating spindle, further enhance the phase insulation performance.

Embodiment 3

[0134] It is mainly in the first embodiment, in Example 1, each phase insulating umbrella skirt is an annular seal umbrella skirt, in the present embodiment, each phase insulating umbrella only has an inner protruding portion and an outer protrusion. Meet the basic insulation interval requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com