Rotary ultrasonic motor driven by multiple feet in bending vibration mode

A technology of bending vibration and ultrasonic motor, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problems of difficult processing, complex stator structure, large volume, etc. , to achieve the effect of small processing difficulty, small overall volume and simple driving control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

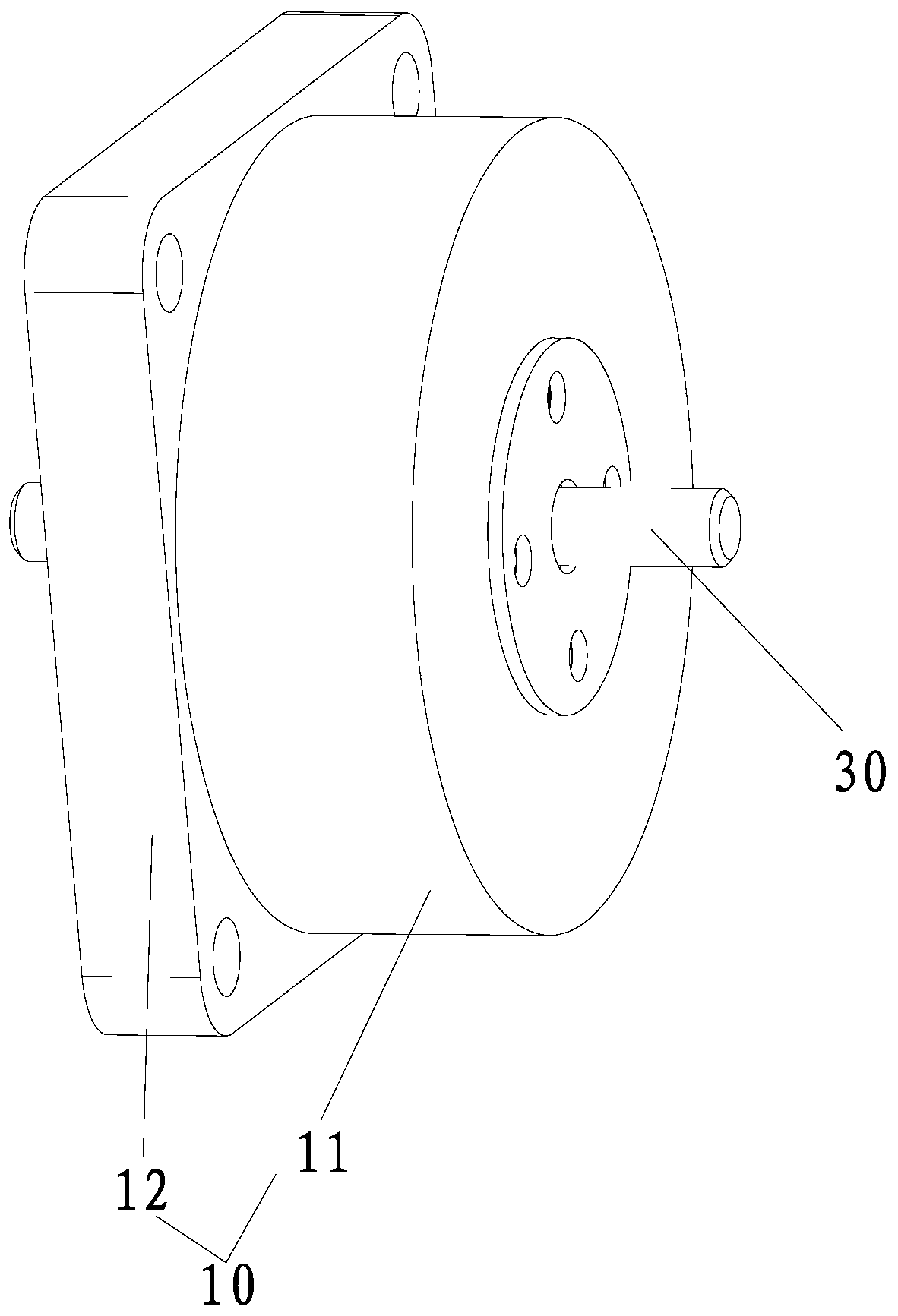

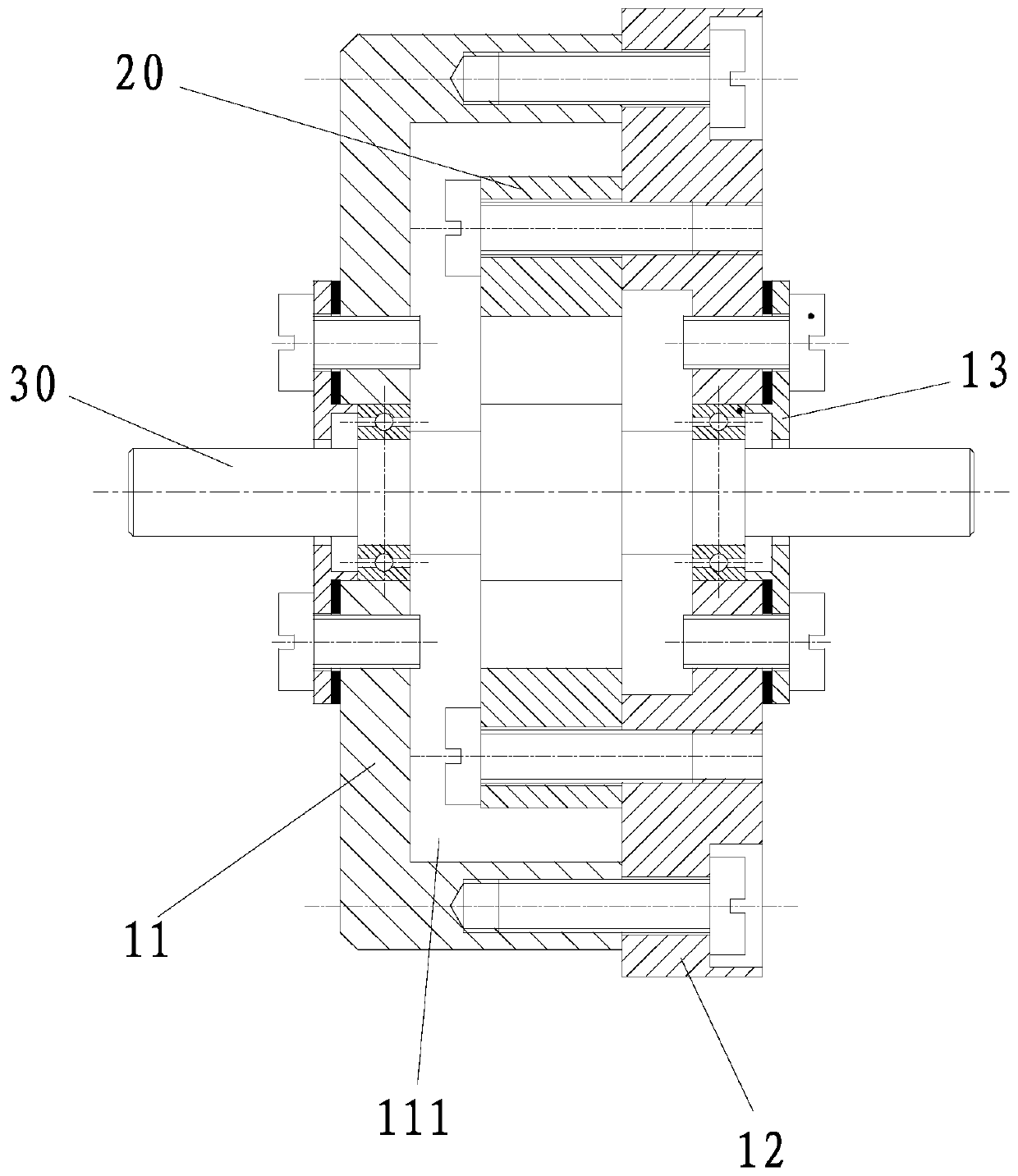

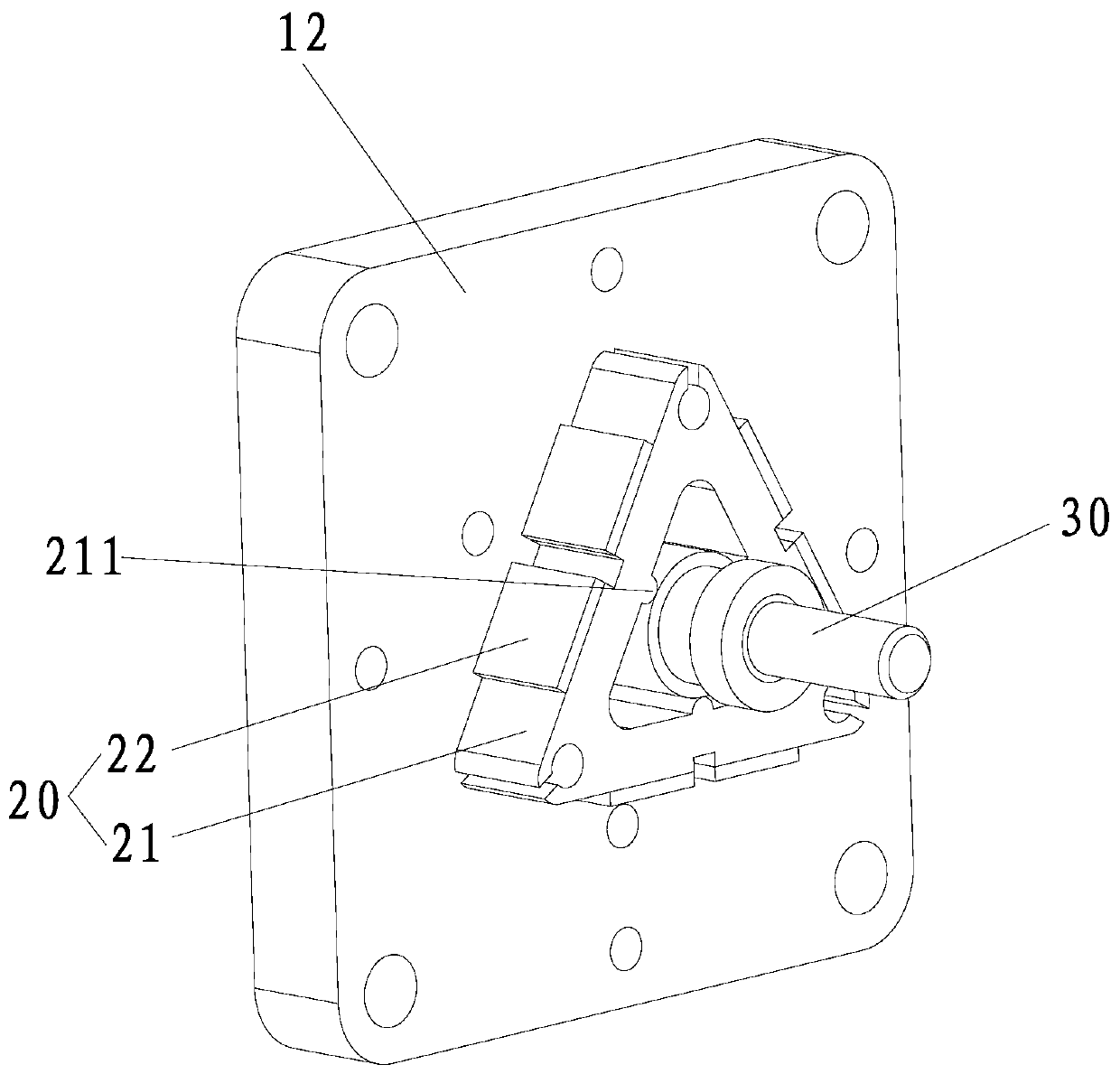

[0029] A rotary ultrasonic motor driven by multi-legs using flexural vibration modes, such as Figure 1-4 As shown, it includes a casing 10, a stator 20, a rotor 30 and a driving power supply. The stator 20 is installed inside the housing 10 , the rotor 20 passes through the stator in a rotatable manner, and the driving power is installed outside the housing 10 , and the driving power can output two independent driving signals.

[0030] Such as Figure 1-4 As shown, the stator 20 includes a polygonal elastic body 21 and a piezoelectric ceramic sheet 22. The polygonal elastic body 21 has a plurality of sides, and each side includes a corresponding outer edge and an inner edge. Each inner edge of the polygonal elastic body 21 The sides together form a hollow part, the above-mentioned rotor 30 passes through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com