Medical cotton ball storage tank with cotton ball extruding and wetting mechanism

A technology for storing cans and cotton balls, applied in the field of machinery, can solve the problems of waste of disinfectant, unfavorable full use of disinfectant, etc., and achieve the effects of improving the wetting effect, reducing the amount of volatilization, and facilitating convergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

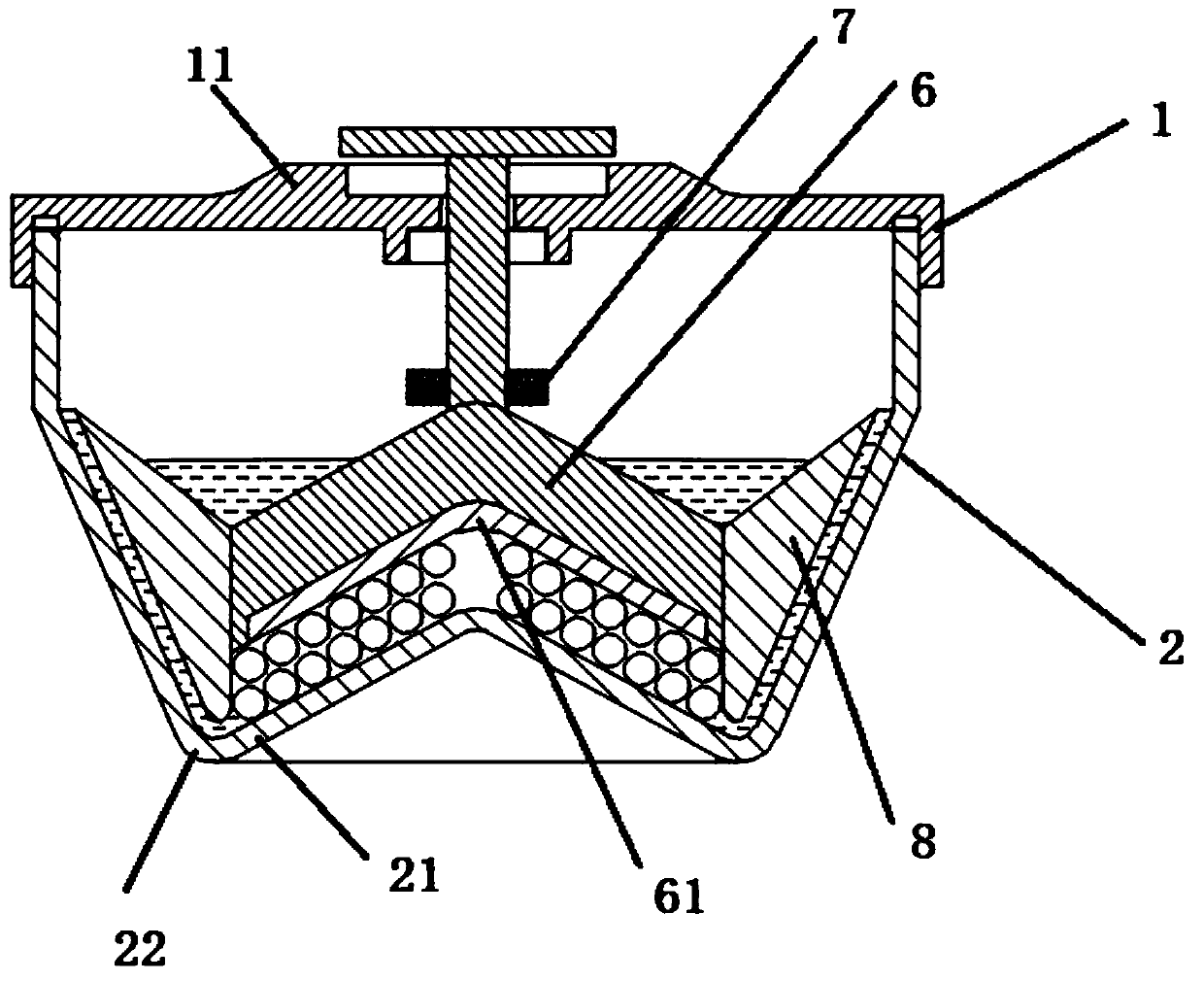

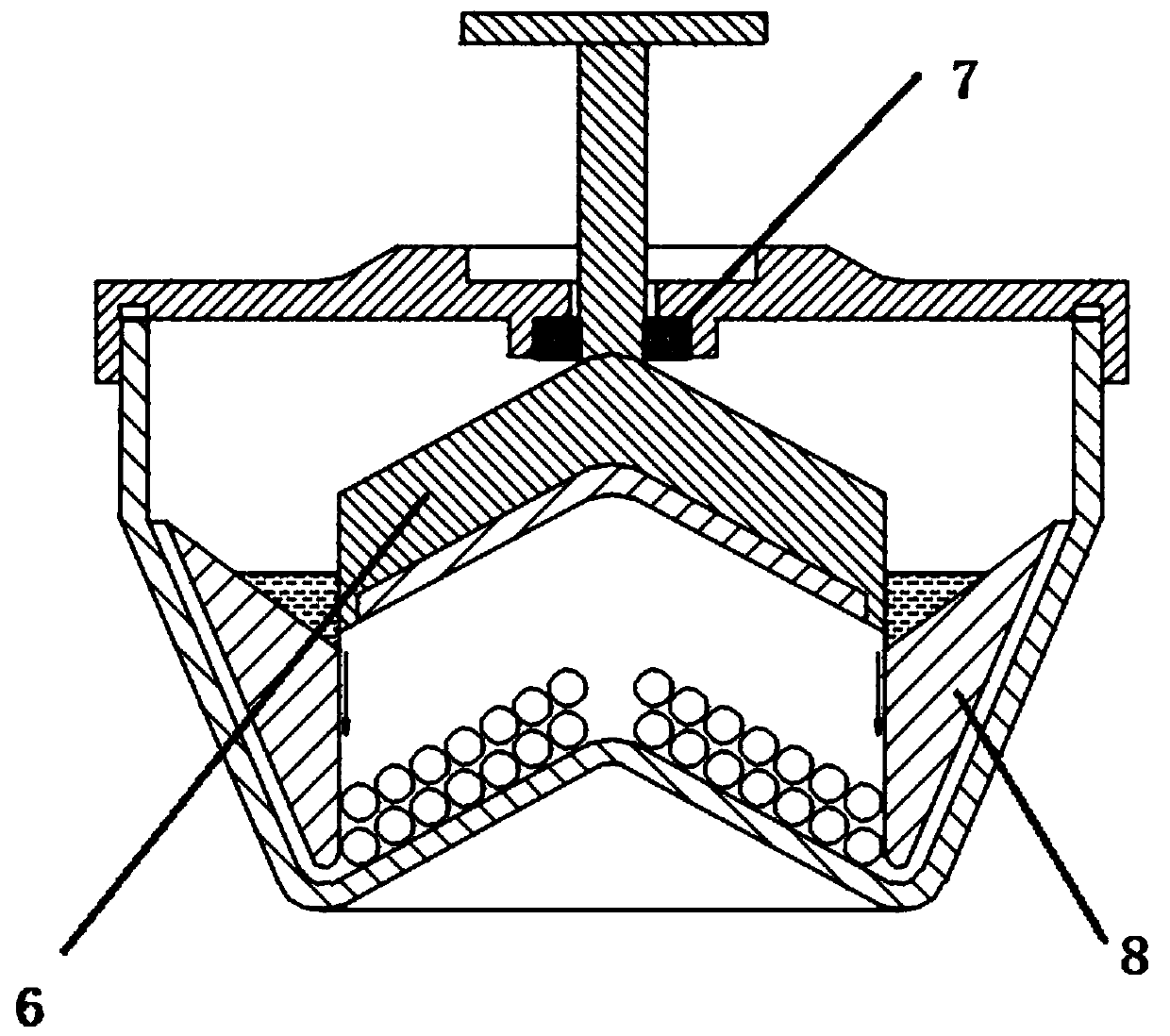

[0046] Specific embodiment 1, see figure 1 as well as figure 2 , a medical cotton ball storage tank with a cotton ball extrusion wetting mechanism, including a tank 2 for storing cotton balls and a tank cover 1, the tank 2 is threaded with the tank cover 1, and the connection between the tank 2 and the tank cover 1 A sealing ring 3 is provided at the place.

[0047] The jar 2 comprises a bottom plate 21 and a side plate, the bottom plate 21 and the side plate are connected by an arc-shaped transition portion 22 to form the jar 2, the bottom plate 21 is a conical bottom plate 21 increasing from top to bottom, the bottom plate 21, the arc-shaped transition portion 22 and The side plates are connected to form a V-shaped annular groove in cross-section, and the annular groove is used as a placement groove for placing cotton balls, and the installation groove is connected with the sealing member by interference fit.

[0048] An annular inner plate 8 is installed in the tank body...

specific Embodiment 2

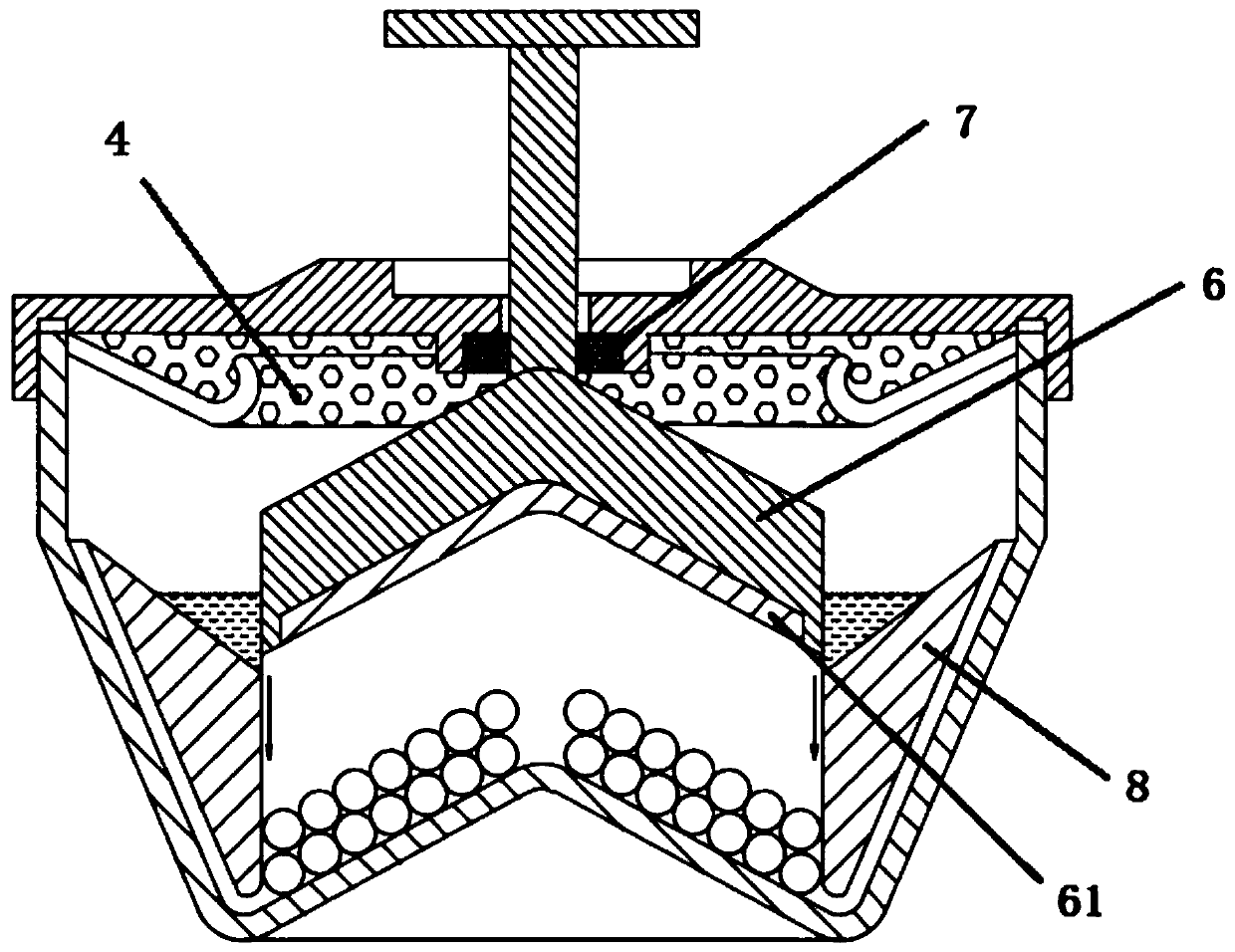

[0057] Specific embodiment 2, see image 3 , on the basis of specific embodiment 1, the side plate includes an upper part and a lower part arranged up and down, the inner diameter of the upper part is equal up and down, and the inner diameter of the lower part decreases from top to bottom; a drain board 4 is connected to the inner side of the top of the top; The vertical projection of the inside is outside the vertical projection of the inner wall of the inner panel 8 . It is convenient for tweezers to take the cotton ball between the inner board 8 and the base board 21. Drain board 4 does not cause disturbance. The draining plate 4 includes a mesh plate inclined downward from the outside to the inside and an arc-shaped upward flange; mesh holes are also opened on the flange. It is convenient to hold the cotton ball with tweezers in hand, and squeeze the drain plate 4 to drain. When a spring is also installed between the piston and the tank cover, the piston is positioned a...

specific Embodiment 3

[0058] Specific embodiment 3, see Figure 4 , on the basis of the specific embodiment 1 or 2, the center of the bottom plate 21 is equipped with a hollow tube with a lower end seal, and the hollow tube is a liquid storage tube 5 for putting in physiological saline; For the cavity where the cotton ball is placed, the inner cavity of the hollow tube communicates with the cavity. By adding the design of the hollow tube, it is convenient to realize the effect of humidifying and moisturizing in the cavity. Further reduce the amount of volatility. The upper end of the liquid storage tube 5 is higher than the highest point of the top plate; the center of the piston 6 is provided with a gap for inserting the liquid storage tube 5 protruding from the top plate area. It is convenient for the liquid storage tube 5 not to interfere with the descending of the piston 6 . A groove is provided at the lower end of the piston 6, and a pressing plate 61 is fixed in the groove. It is convenie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com