A kind of monosodium glutamate production resin column decolorization automatic control system and its automatic control method

An automatic control system and resin column technology, applied in separation methods, comprehensive factory control, chemical instruments and methods, etc., to ensure efficient and reliable operation, avoid material waste, and ensure the effect of enterprise production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

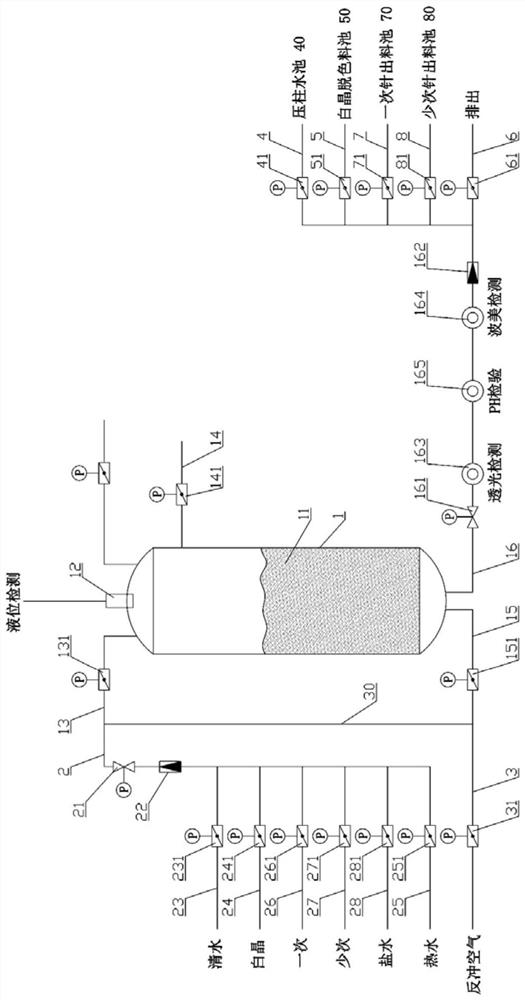

[0086] refer to figure 1, a kind of monosodium glutamate production resin column decolorization automatic control system, it comprises resin column decolorization tank 1. The resin column decolorization tank 1 is provided with a resin column 11 and a liquid level gauge 12, and the liquid level gauge 12 is an ultrasonic liquid level gauge. The top of the resin column decolorization tank 1 is connected with a feed main pipe 13 and a backwash discharge pipe 14 , and the bottom is connected with a backwash feed pipe 15 and a discharge main pipe 16 .

[0087] The feed main pipe 13 is provided with a positive inlet control valve 131, and its end is connected with a feed connecting pipe 2, and the feed connecting pipe 2 is successively provided with a feed regulating valve 21 and a feed flow meter 22, and its ends are respectively Connected with clear water feed pipe 23, white crystal feed pipe 24, primary needle feed pipe 26, few needle feed pipe 27, salt water feed pipe 28 and hot...

Embodiment 2

[0093] A kind of monosodium glutamate production resin column decolorization automatic control method, it adopts the monosodium glutamate production resin column decolorization automatic control system of embodiment 1, liquid level gauge 12 is used for detecting the liquid level in resin column decolorization tank 1, feed flowmeter 22 is used for Detect the feed flow rate of the material flowing through the feed connecting pipe 2. The discharge flow meter 162, the light transmission online detector 163, the pH value online detector 165 and the Baume degree online detector 164 are used to detect the flow through the discharge main pipe. 16 The discharge flow rate, light transmittance, pH value and Baume degree of the material.

[0094] The method for automatically controlling the decolorization of the resin column for monosodium glutamate production in this embodiment sequentially includes a white crystal column loading process, a white crystal column pressing process, and a res...

Embodiment 3

[0122] A kind of monosodium glutamate production resin column decolorization automatic control method, it adopts the monosodium glutamate production resin column decolorization automatic control system of embodiment 1, liquid level gauge 12 is used for detecting the liquid level in resin column decolorization tank 1, feed flowmeter 22 is used for Detect the feed flow rate of the material flowing through the feed connecting pipe 2. The discharge flow meter 162, the light transmission online detector 163, the pH value online detector 165 and the Baume degree online detector 164 are used to detect the flow through the discharge main pipe. 16 The discharge flow rate, light transmittance, pH value and Baume degree of the material;

[0123] The method for automatically controlling the decolorization of the resin column for monosodium glutamate production in this embodiment sequentially includes a few-time column loading process, a small-time column pressing process, and a resin colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com