Waste gas treatment system

A technology for waste gas treatment and waste gas purification, used in gas treatment, separation methods, and dispersed particle separation. Efficient processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

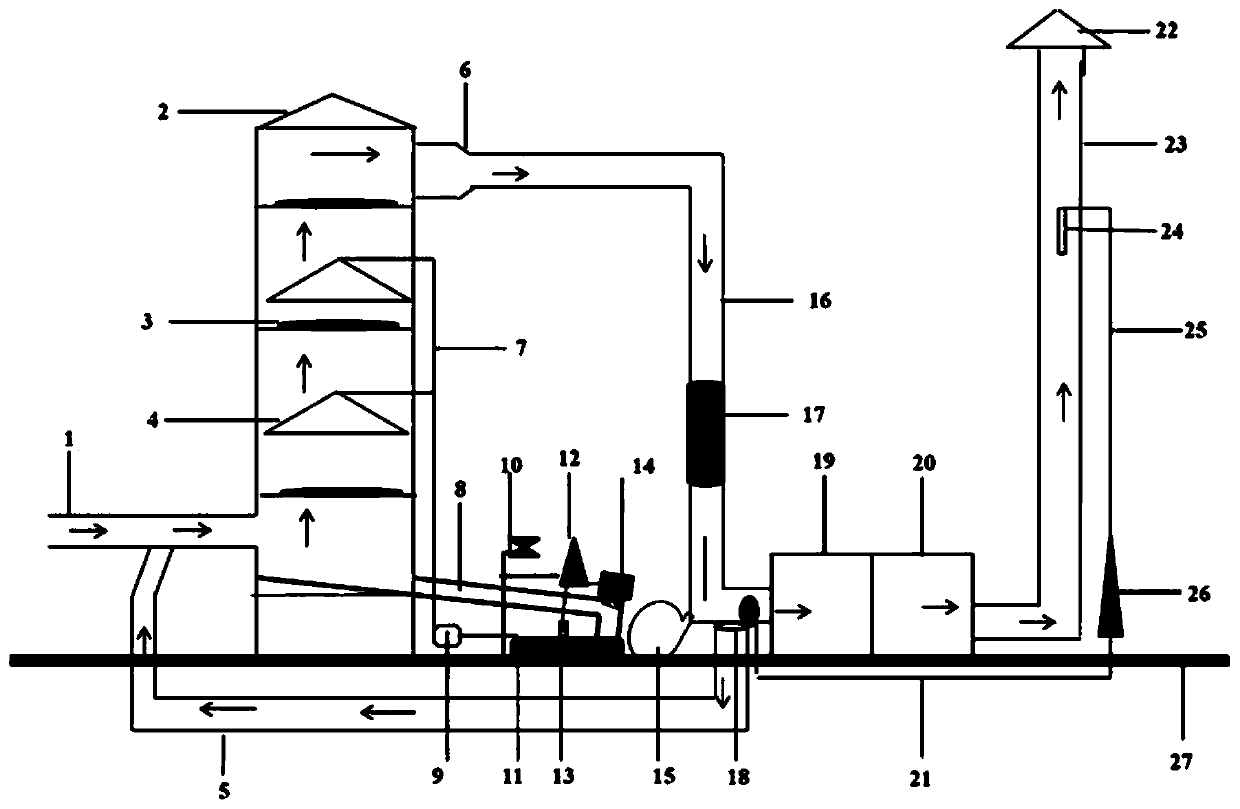

[0016] The present invention provides a waste gas treatment system including a starting gas transmission pipe 1, a waste gas purification tower 2, a swirl plate 3, a spray head 4, a return pipe 5, a conversion head 6, a water pipe 7, an outlet pipe 8, a water circulation pump 9, Faucet 10, spray pool 11, control box 12, pH probe 13, pH buffer storage tank 14, frequency conversion fan 15, mid-section gas pipeline 16, water mist separator 17, steering valve 18, activated carbon adsorption equipment 19, UV light Oxygen catalytic processing equipment 20 , sensing lines 21 and 25 , chimney umbrella head 22 , chimney 23 , detection head 24 , control cabinet 26 and platform 27 .

[0017] In the system, the starting gas transmission pipe 1 is connected to the lower part of the exhaust gas purification tower 2, and the starting gas transmission pipe 1 transmit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com