Lithium ore flotation method and collector composition

A composition and collector technology, applied in flotation, solid separation and other directions, can solve the problems of many collector components, complex preparation process, large amount of flotation reagents, etc., to overcome the low selectivity and molecular arrangement. The effect of tightness and increasing flotation yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

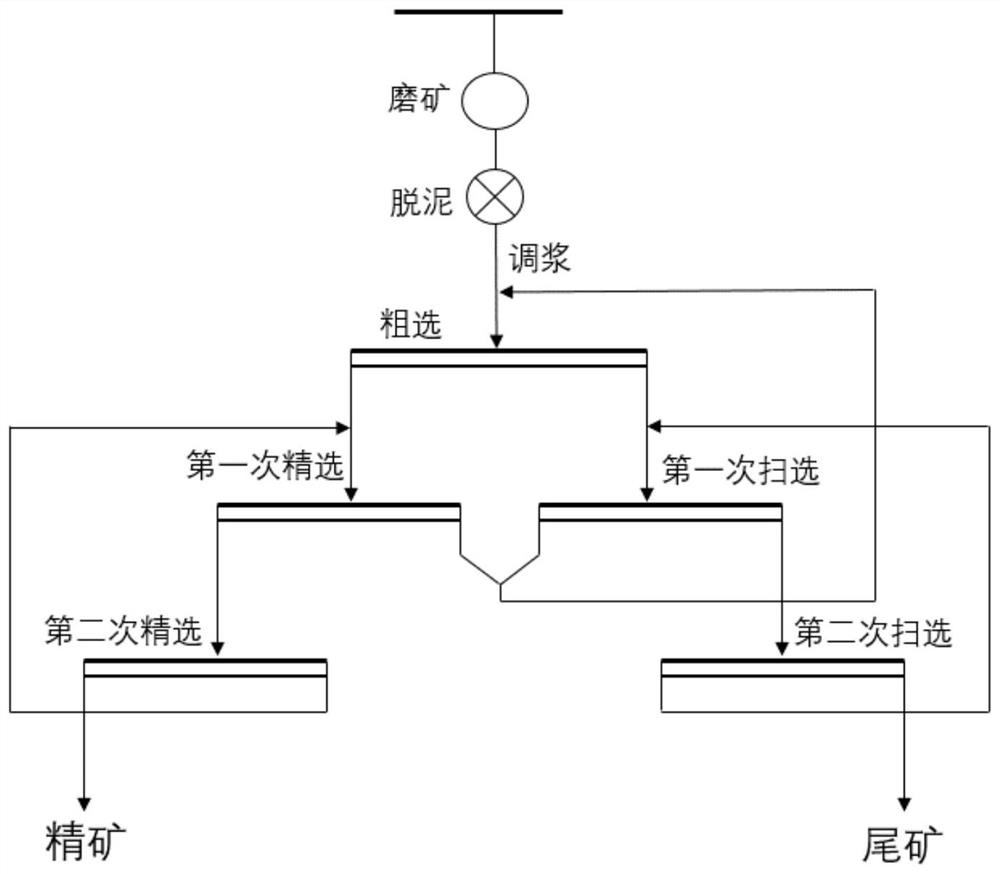

[0044] The lithium ore employed in this embodiment is a primestite, including Li 2 O1.48%, mainly lithium glow, mica and longite. See figure 1 As shown, the flotation method of the lithium ore includes the steps of:

[0045] S1, crushing lithium ore, grinding to particle size 0.050 ~ 0.075 mm content accounts for 80%, and water is made of water;

[0046] S2, NaOH to pH 12 was added to the slurry, and stirred and demetrifies 50 min to give lithium mine slurry at a dense mine slurry concentration of 35%;

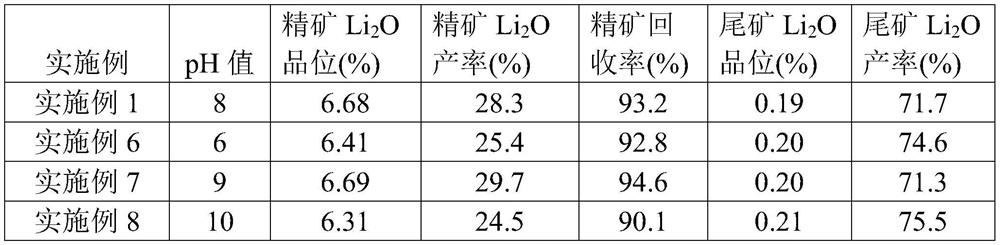

[0047] S3, using HCl and / or NaOH to slurry the lithium mine slurry, adjusting to a pH of 8, adding the captain composition, performing a coarse selection twice a second selection of flotation processes Lithium concentrate and tailings.

[0048] Among them, the capture reagent composition is a coolant ion mixed collector composition, including anionic capture agent sulfonic acid-modified octorate and cationic capture, carboxy-modified dodecine; and each component According to the...

Embodiment 2

[0056] The lithium ore employed in this embodiment is a primestite, including Li 2 O1.08%, mainly containing lithium glow, mica and long stone. The flotation method of the lithium ore includes the following steps:

[0057] S1, crushing lithium ore, milling to particle size of 0.050 to 0.075 mm, 85%, and add water to a slurry;

[0058] S2, NaOH to pH is 12 in the slurry, and stirred and demetrifies 50 min, resulting in a lithium mine slurry having a concentration of 30% after dense.

[0059] S3, using HCl and / or NaOH to slurry the lithium ore slurry, adjusted to a pH of 10, adding the capture agent composition, and performing a quadratic selection of two selection Lithium concentrate and tailings.

[0060] Among them, the capture reagent composition is a coolant ion mixed collector composition, including anionic capture agent sulfonic acid-modified octorate and cationic capture, carboxy-modified dodecine; and each component According to the following mass percentage: sulfonic aci...

Embodiment 3-5

[0070] Unlike Example 1, the ratio of component mass fractions in the catching agent composition is different, and other steps are the same as that, and will be described later herein.

[0071] Table 1 is provided in Example 1, Example 3-5.

[0072] Example Sulfonic acid-based modified octorate Carboxy-modified octamine Example 1 60% 40% Example 3 70% 30% Example 4 50% 50% Example 5 40% 60%

[0073] The collecting agent composition provided by the present invention is anhano-censoon mixed collector composition, wherein the sulfonic acid-based modified octorate is an anionic capture agent, carboxy-modified octine is a cationic capture agent, In the flotation process, the receptacle composition can synergistically, improve the floating value yield, and the synergistic mechanism is as follows: 1) The electrically conductive dieamine is by electrostatic active lithium ore surface. Adsorption occurs, and the sodium of the negative modified octorat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com