Rapid paint sprayer for atomizing and removing flow falling orange peel of hardware plate disc type fin

A paint sprayer and plate technology, applied in the direction of spraying devices, spraying devices, etc., can solve the problems of reduced protection of metal plates, affecting the water seepage of the plates, and reducing the service life of the plates, achieving obvious protection effects, small gap density between plates, The effect of high usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

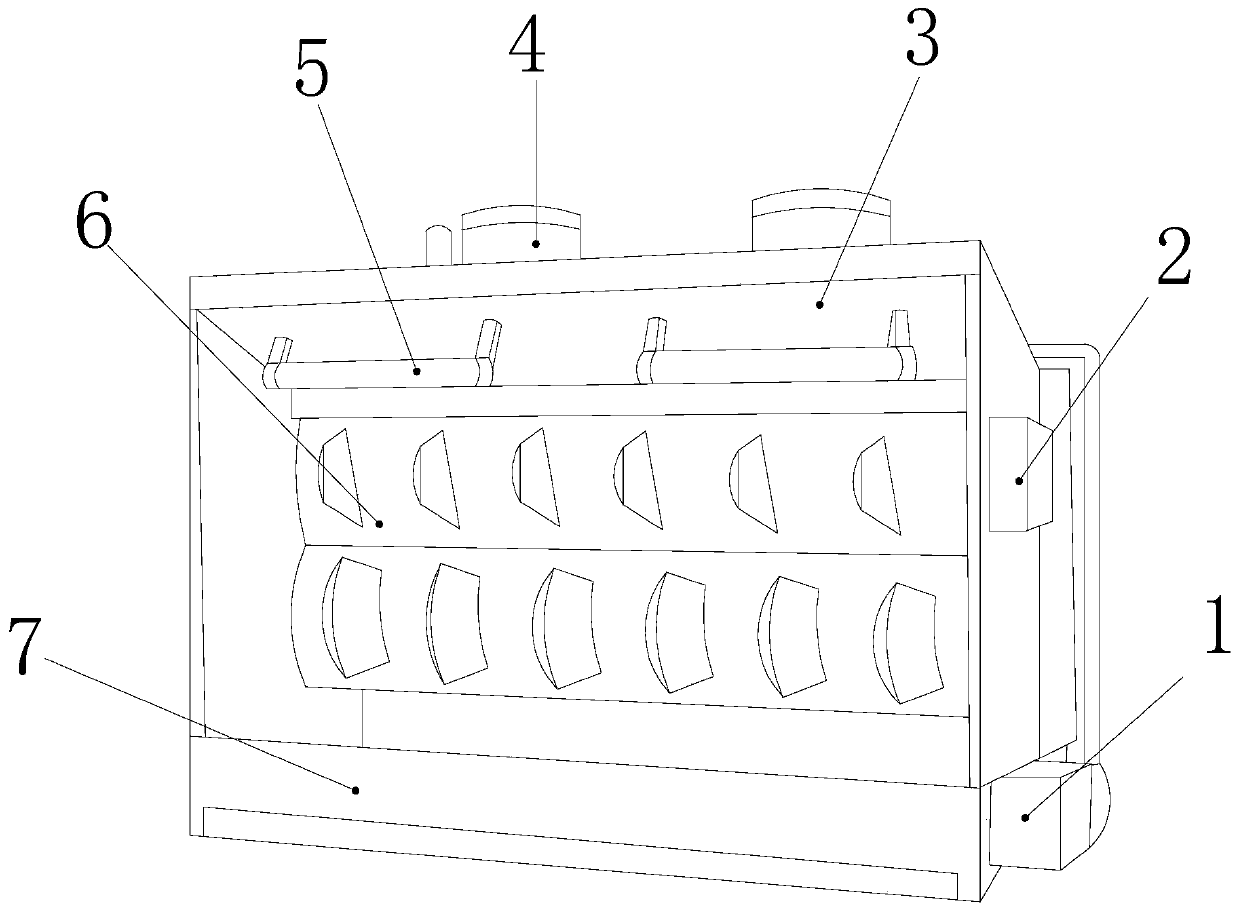

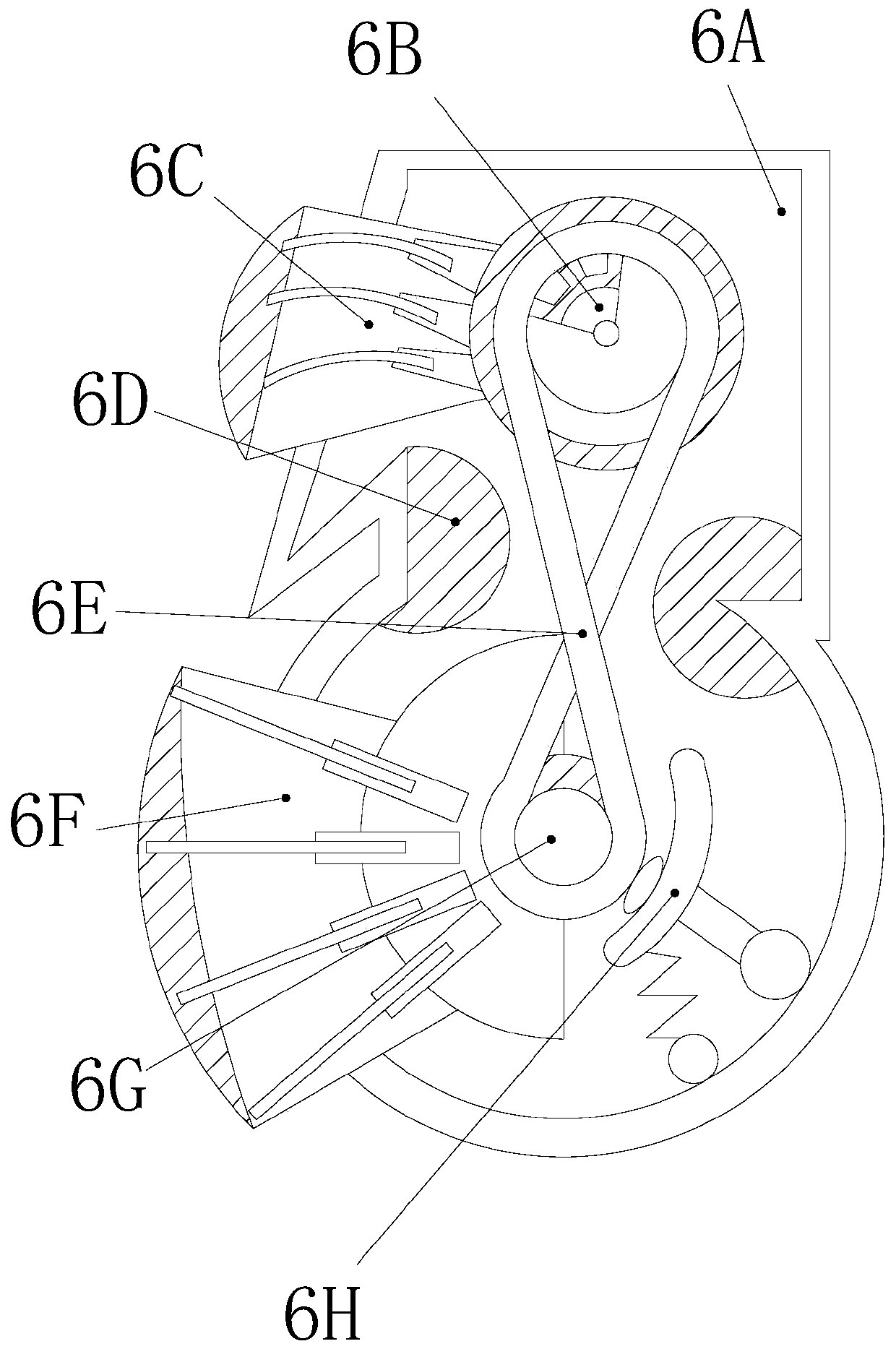

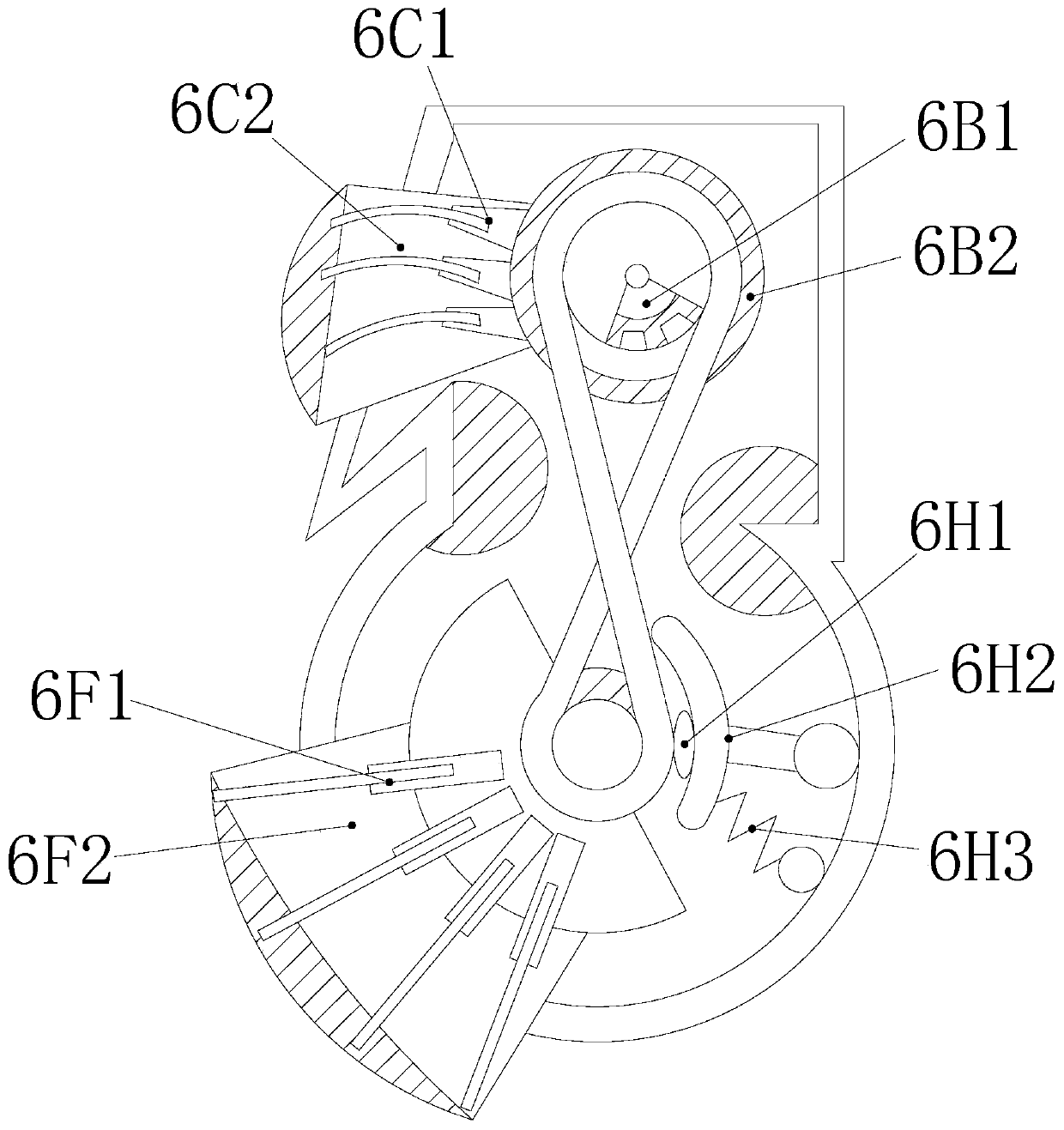

[0033] see Figure 1-Figure 7 , the present invention provides a fast paint sprayer for atomizing disc fins on metal plates to remove falling orange peels. Hanger 5, fin spraying device 6, filter base 7, said fin spraying device 6 is installed inside the square inner tank 3, said filter base 7 is closely attached to the bottom surface of the square inner tank 3 and penetrates each other, so The liquid collection return box 1 is nested on the right side of the filter base 7, the electric control box 2 is close to the right side of the square inner tank 3, and the plate hanger 5 is provided with two and are all inserted in the square Inside the tank 3, the paint cans 4 are provided with two and are vertically attached to the rear side of the square ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com