Quick-change clamp switching frame without manual operation

A manual operation and automatic switching technology, applied in the direction of manufacturing tools, welding/cutting auxiliary equipment, auxiliary devices, etc., to achieve the effect of avoiding manual operation, improving automation and reducing labor burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

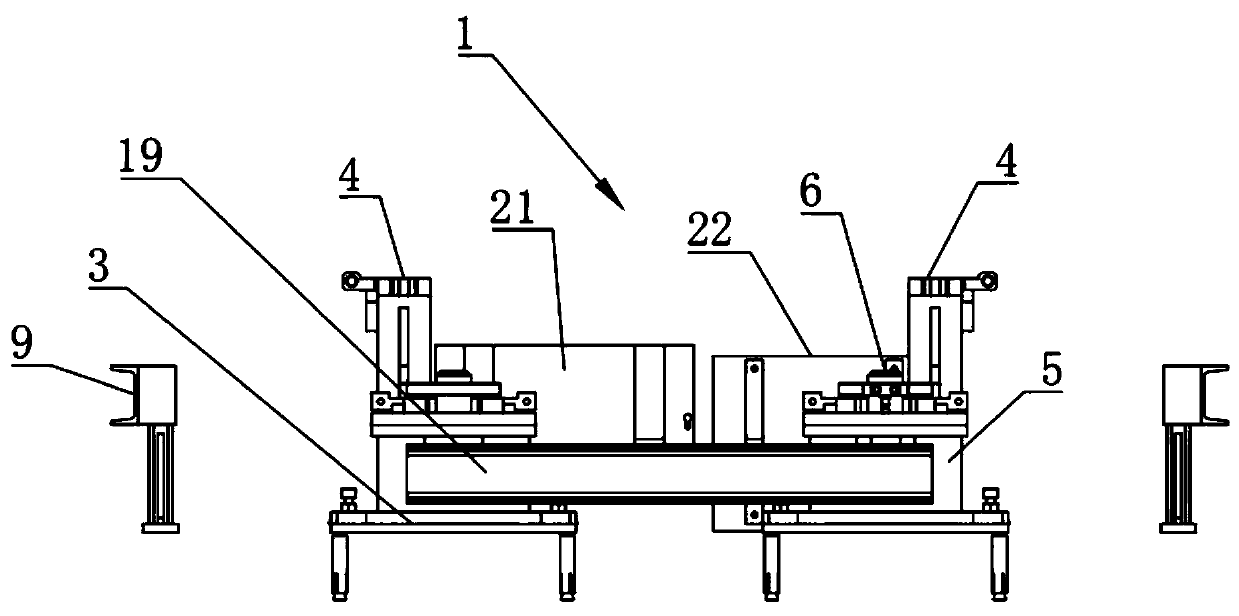

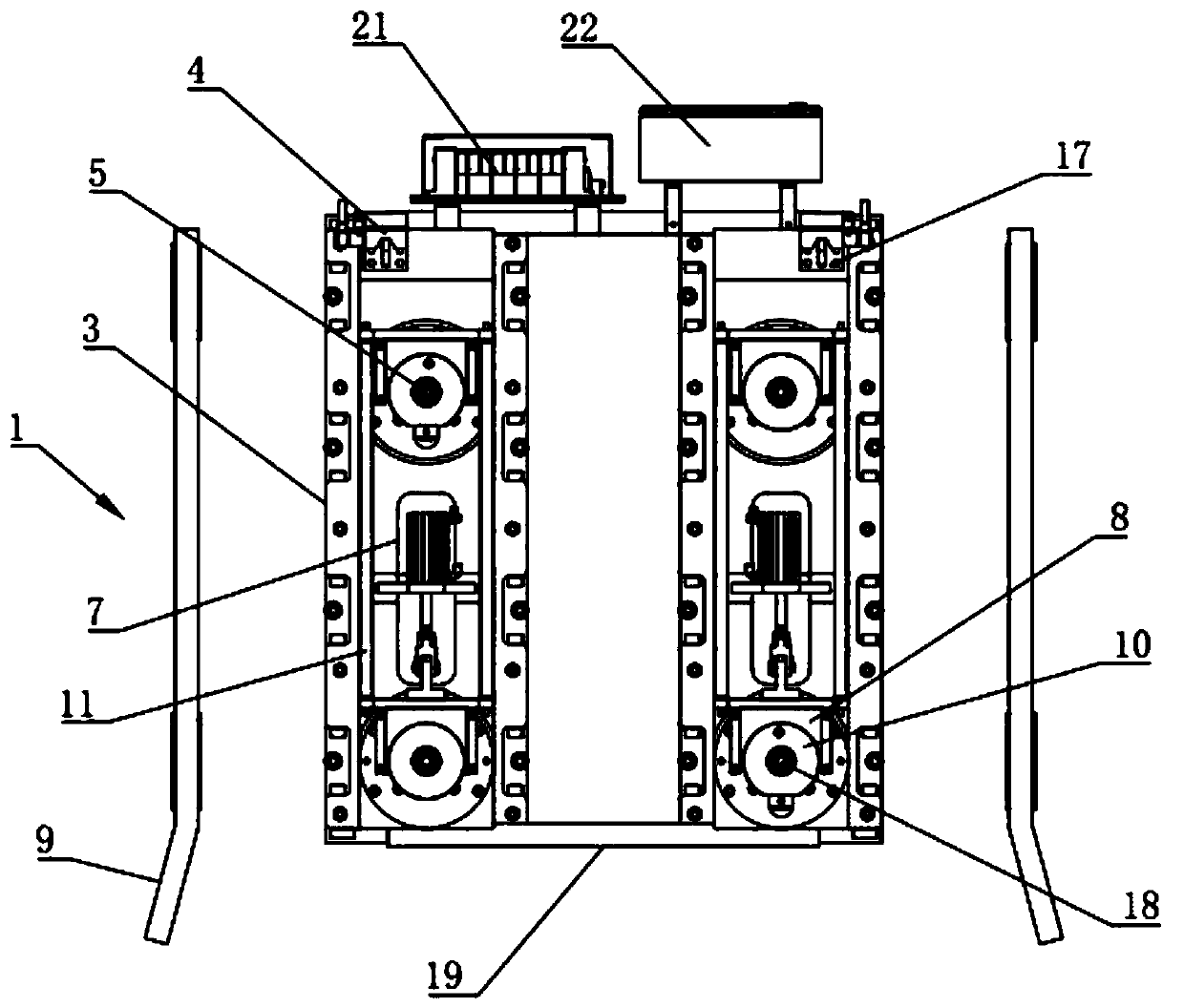

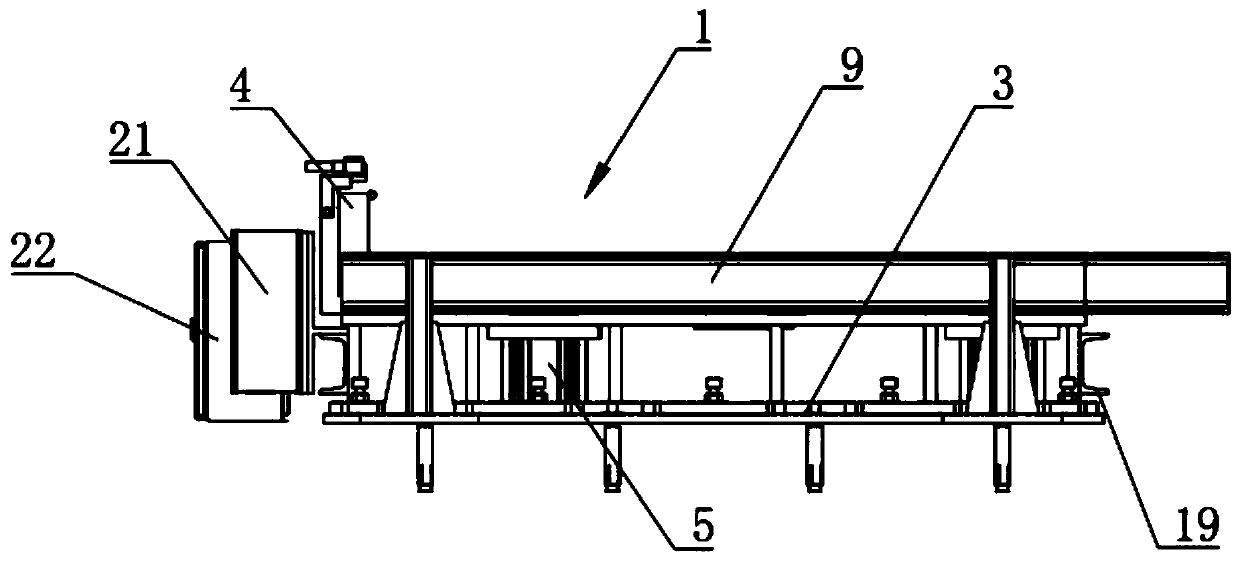

[0039] Such as Figure 1-13 As shown, a clamp quick-change switching rack that does not require manual operation includes a static automatic switching device 1 and a clamp 2 .

[0040] Such as Figure 1-4 As shown, the static automatic switching device 1 includes a bracket 3, a first limit block 4, a positioning cylinder 5, a supporting cylinder 7, a spacer 8 and two guide grooves 9, and the two guide grooves 9 are symmetrically arranged on The left and right sides of the bracket 3; as Figure 13 As shown, the support 3 is a cuboid structure, the two ends of the support 3 along the length direction are respectively provided with a positioning cylinder installation cavity, and a support cylinder installation cavity is provided between the two positioning cylinder installation cavities; the first The limit block 4 is arranged at one end of the upper surface of the support 3 in the length direction; the positioning cylinder 5 has two, which are respectively arranged in the inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com