Ethylene cracking furnace cracking gas pipeline decoking system and cracking gas pipeline anti-coking and decoking method

A technology of ethylene cracking furnace and cracking gas, which is applied in the direction of cracking, hydrocarbon cracking to hydrocarbon, non-catalytic thermal cracking, etc. It can solve the problems of filter clogging and multi-stage coke catcher cost increase, so as to reduce investment costs and solve switch Difficult, prolonged operating cycle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

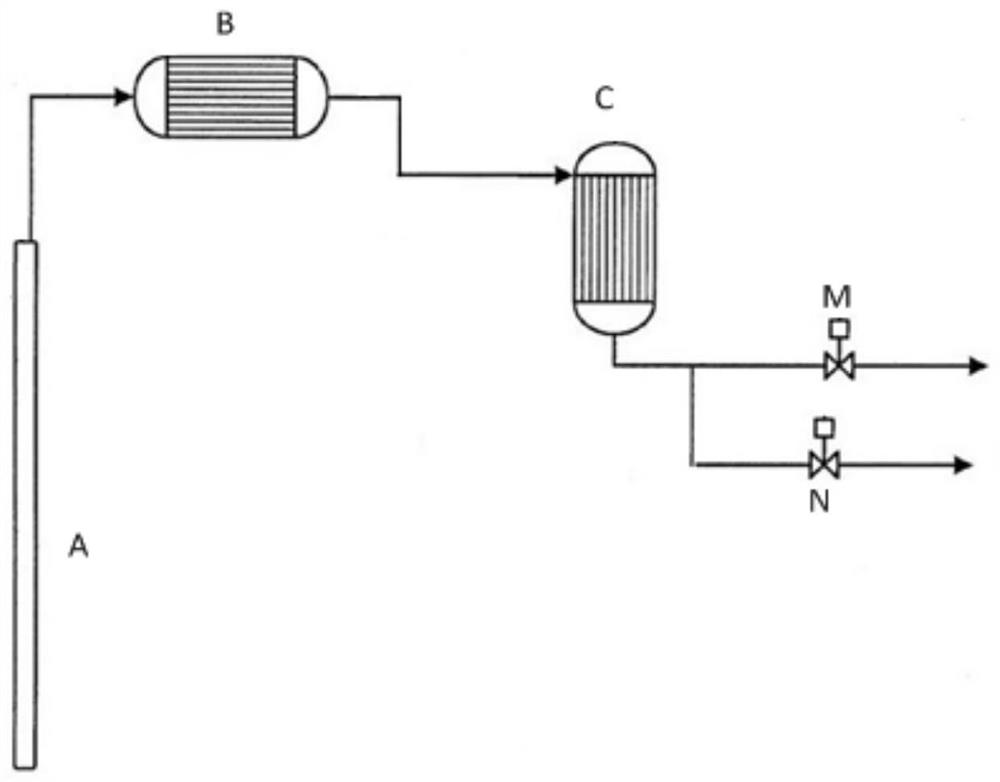

[0057] use as Figure 5 The coke prevention layout trend diagram of cracking gas pipeline decoking system of ethylene cracking furnace is shown for decoking of cracking gas pipeline. When the cracking furnace is in normal operation and cracking gas phase raw materials, the high-temperature cracking gas from the furnace tube in the radiant section is cooled by all levels of quenching heat exchangers and then moves horizontally to the front of the cracking gas valve. The pipeline where the cracking gas valve is located is from the horizontal cracking gas pipeline. The top is extracted upwards, and the cracked gas passes through the upwardly drawn pipeline (branch 1) and then enters the downstream system through the horizontal arrangement section equipped with a large cracked gas valve. This upward extraction method can make the coke particles generated in the furnace tube and quenching heat exchanger during normal operation gather at the blind end reserved for the pyrolysis gas ...

Embodiment 2

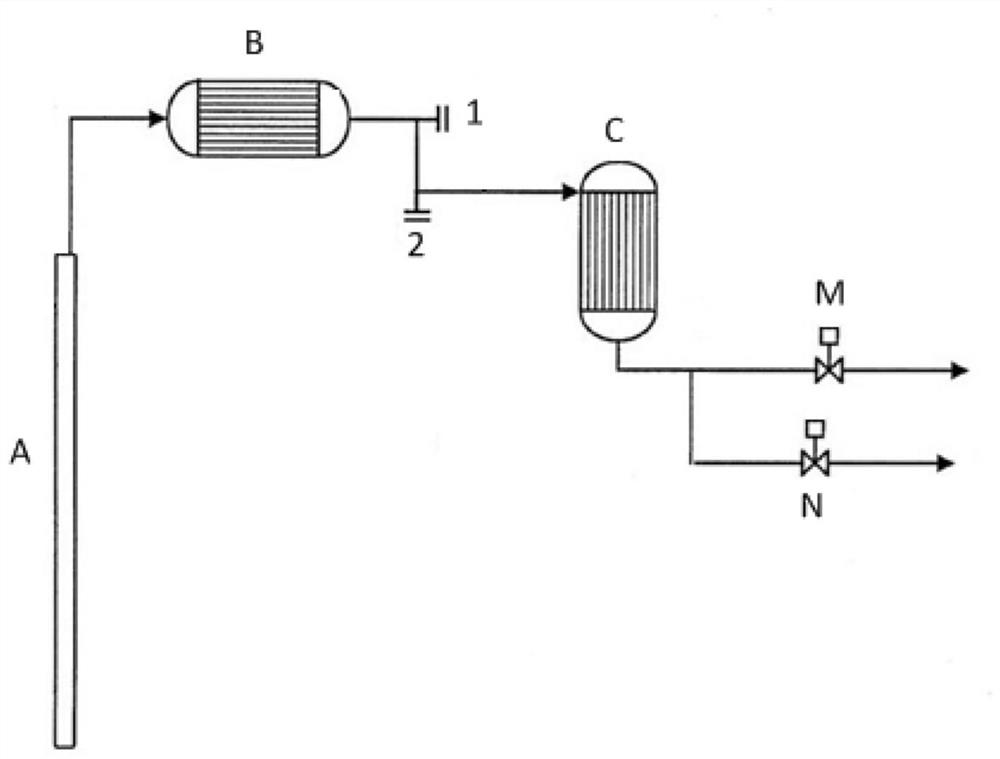

[0059] use as Figure 6 The coke prevention layout trend diagram of cracking gas pipeline decoking system of ethylene cracking furnace is shown for decoking of cracking gas pipeline. When the cracking furnace is operating normally and cracking the gas phase feedstock, with Figure 5 The difference of the provided embodiment 1 is that in the direction of the cracking gas pipeline, the coke cleaning pipeline (branch 2) where the coke cleaning valve is located is extracted from the side of the cracking gas pipeline, and is connected with the pipeline where the cracking gas large valve is located. (Branch 1) on the same side. Depend on Figure 6 It can be seen that during normal operation, the coke particles produced in the cracked gas pipeline, furnace tube and quenching heat exchanger will enter the blind end reserved for the cracked gas pipeline with potential energy, avoiding the coke particles in the cracked gas valve and coke cleaning. Buildup at the valve.

Embodiment 3

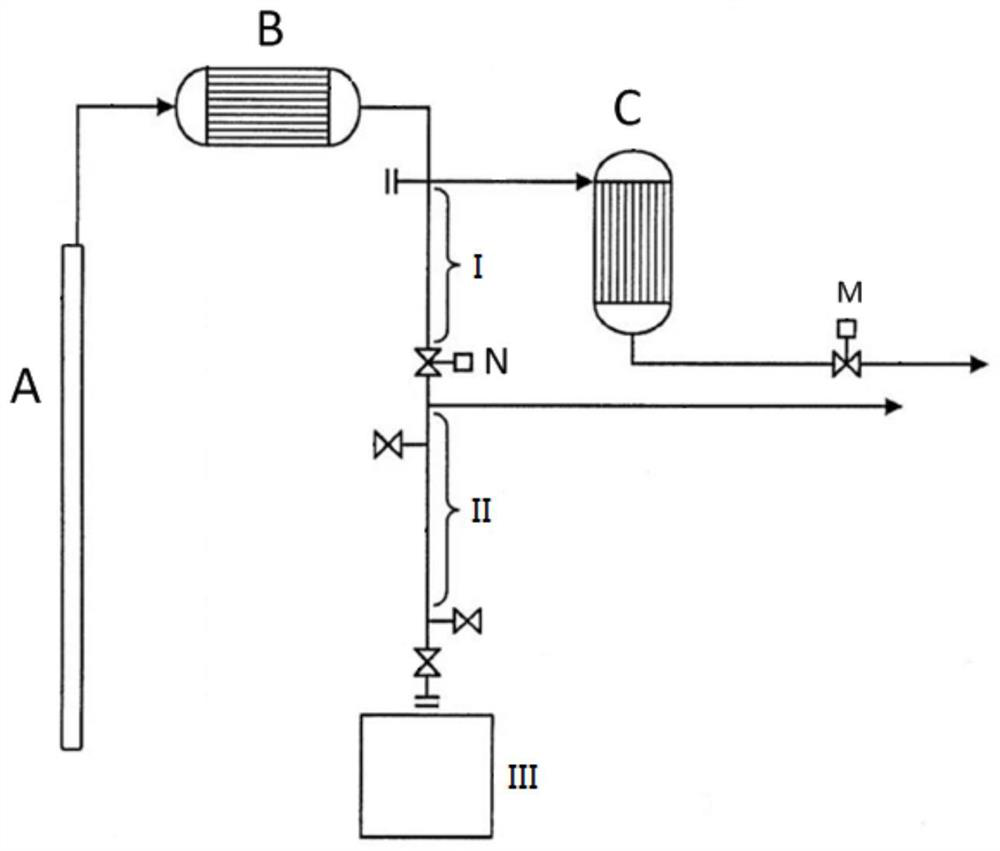

[0061] use as Figure 7 The coke prevention layout trend diagram of cracking gas pipeline decoking system of ethylene cracking furnace is shown for decoking of cracking gas pipeline. When the cracking furnace is operating normally and cracking the gas phase feedstock, with Figure 6 The difference of the provided embodiment 2 is that in the trend of the cracking gas pipeline, the coke cleaning pipeline (branch 2) where the coke cleaning valve is located is drawn upwards from the top of the cracking gas pipeline, which can avoid the normal operation of the cracking furnace When the coke particles in the pipeline accumulate in front of the coke cleaning valve, it will cause the coke cleaning valve to be blocked and difficult to open. Depend on Figure 7 It can be seen that during normal operation, the coke particles produced in the cracked gas pipeline, furnace tube and quenching heat exchanger will enter the blind end reserved for the cracked gas pipeline with potential energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com