A feeding device and alignment input device with the feeding device

A technology of input equipment and input mechanism, applied in lighting and heating equipment, conveyor control devices, packaging, etc., can solve the problems of insufficient adaptability and inability to adapt to liquid crystal panels of different sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

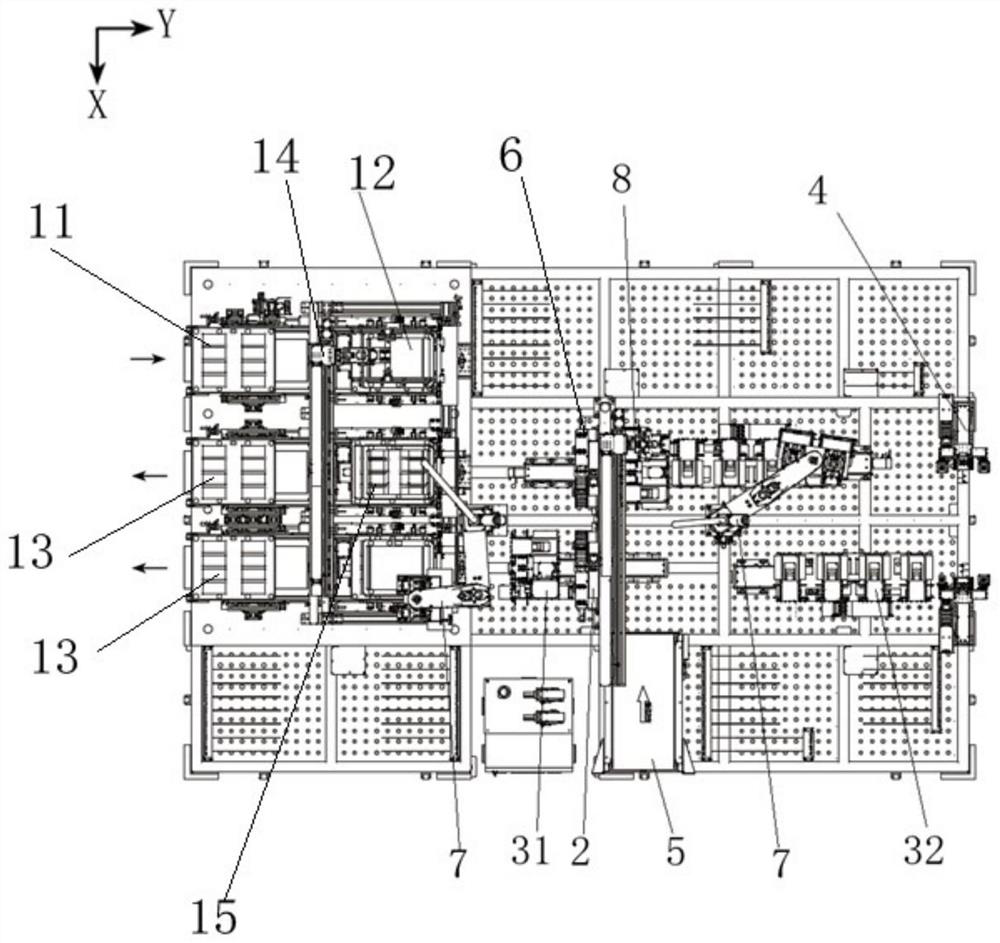

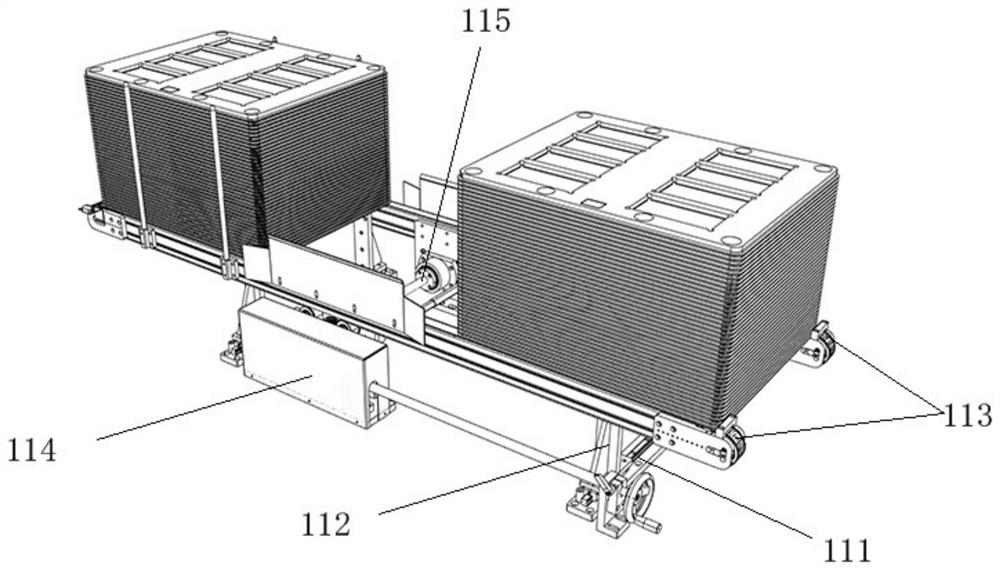

[0118] This embodiment provides a loading device, including: a full tray input mechanism 11, a tray separation assembly 12, a tray stacking assembly 15, at least one empty tray output mechanism 13 (two in Fig. 1a ) and a tray handling manipulator 14. The pallet handling manipulator 14 is used to transfer the pallet from the full pallet input mechanism 11 to the empty pallet output mechanism 13, and the empty pallet is transported away by the empty pallet output mechanism 13, and the pallet separation assembly 12 is set on the full pallet The end of the conveyor line of the input mechanism 11;

[0119] Full tray input mechanism 11 and empty tray output mechanism 13 (the transmission direction of the two mechanisms is opposite), such as figure 2 As shown, each includes two parallel belt adjustment slide rails 111 arranged along the X direction, a sliding mount 112 arranged on the belt adjustment slide rail 111, two parallel belt lines 113 arranged on the slide mount 112, The s...

Embodiment 2

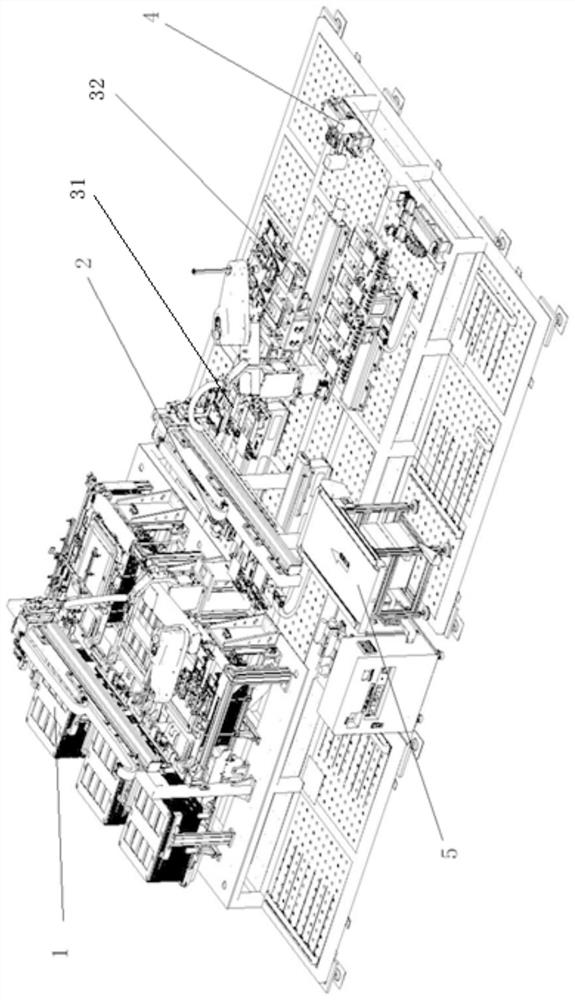

[0127] This embodiment provides an alignment input device, such as Figure 1a and Figure 1b shown, including:

[0128] Feeding device 1, as shown in embodiment 1;

[0129] The transfer platform device 31 is used to accept the liquid crystal panel on the tray from the tray separation assembly 12;

[0130] The ultrasonic cleaning device 2 is arranged above the transfer platform device 31, and is used to clean the liquid crystal panel on the transfer platform device 31. The ultrasonic cleaning device 2 sends ultrasonic waves and blowing gas to the liquid crystal panel on the transfer platform device 31, and passes through the ultrasonic wave. The cleaning device 2 cleans the liquid crystal panel;

[0131] The temporary storage platform device 32 is used to accept the liquid crystal panel on the transfer platform device 31;

[0132] The position alignment device 4 has a position alignment camera 42 (the camera 42 can also be arranged on the slide rail 41 to adjust the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com