On-site adaptive mbbr treatment device and sewage treatment method using the same

A sewage treatment method and technology of treatment devices, which are applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of the wide distribution of MBBR fillers, the interference of sewage treatment capacity, and the use effect. In order to improve the sewage treatment capacity, improve the sewage treatment effect and use the effect better

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

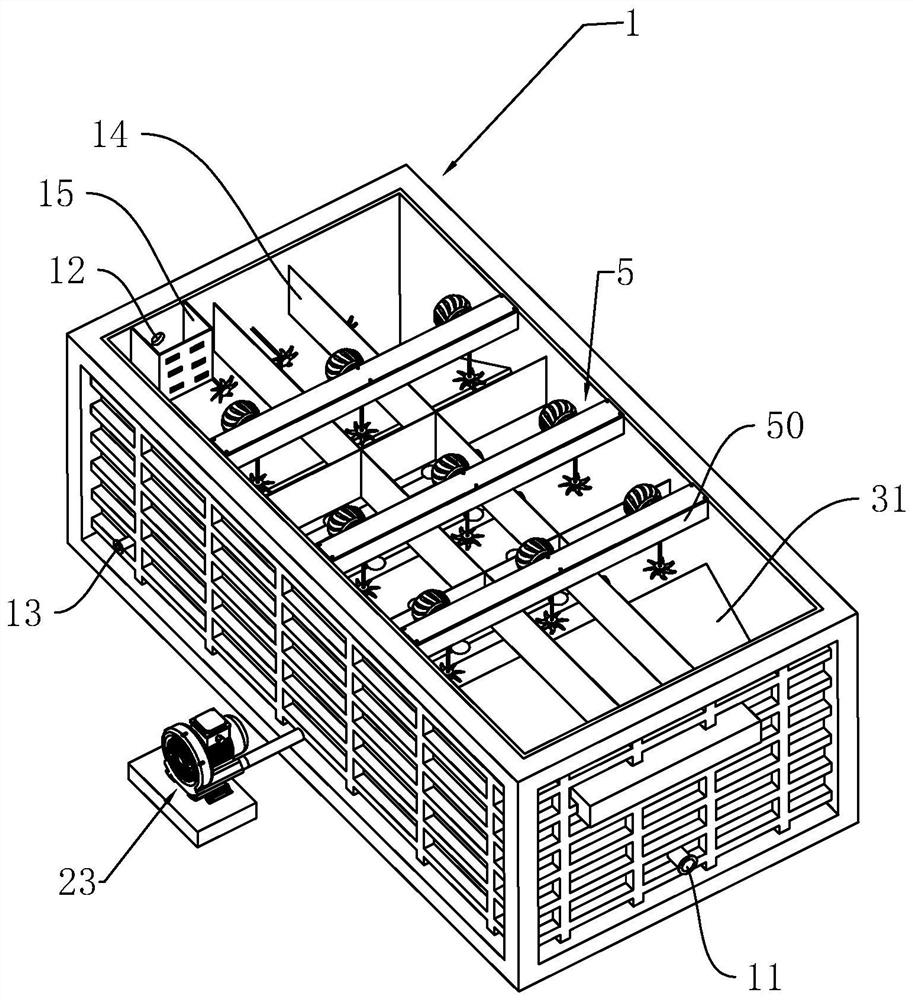

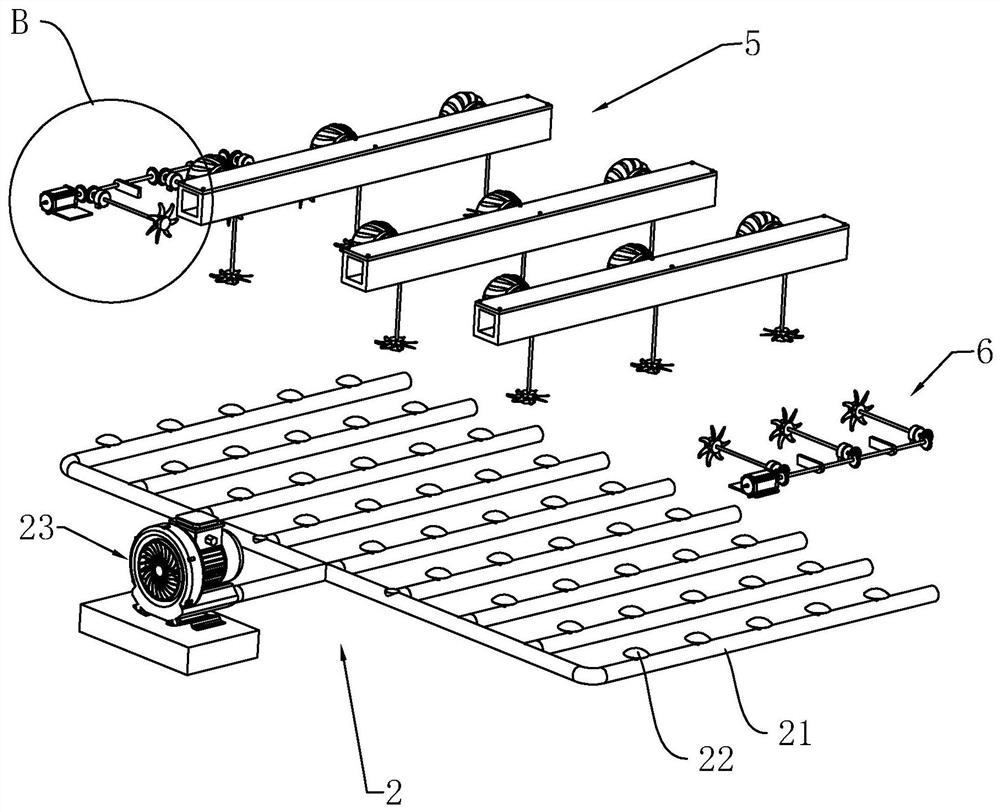

[0040] On-site adaptive MBBR processing device, refer to figure 1 and figure 2 , including a box body 1, an aeration device 2 and an aeration guide device 3 installed in the box body 1, wherein the box body 1 can be welded (riveted) on-site by carbon steel, taking a rectangular parallelepiped box body as an example, the inside The cavity is an upper opening structure. A water inlet pipe 11 communicating with the inner cavity is fixed on one side of the box body 1, and a water outlet pipe 12 communicating with the inner cavity is fixed on the upper part of the opposite side of the box wall; the lower box wall of the box body 1 is also fixed with a The emptying pipe 13 communicated with it.

[0041] refer to figure 2 and image 3 , the aeration device 2 includes a plurality of gas pipelines 21 evenly laid on the inner bottom surface of the box body 1 and fixed, and a plurality of aeration disks 22 are uniformly installed on the gas pipeline 21; the size of the box body 1 i...

Embodiment 2

[0053] On-site adaptive MBBR processing device, refer to figure 1 , the difference from Embodiment 1 is that it also includes a water quality detection device 7 and an on-site control device 8, wherein the water quality detection device 7 can choose an ammonia nitrogen online analyzer, and its sampling end (probe) is placed at the inlet of the outlet pipe 12 of the box body 1. water end side.

[0054] A filter plate 15 is fixed around the water inlet side of the outlet pipe 12 in the casing 1 , and the aperture on the filter plate 15 is smaller than the size of the MBBR filler to prevent the MBBR filler from breaking away from the casing 1 . The sampling end of the ammonia nitrogen online analyzer can be placed in a cavity surrounded by a plurality of filter plates 15 .

[0055] refer to Figure 6 , the on-site control device 8 includes a PLC controller 81, and the electrical signal of the PLC controller 81 is connected to the output end of the ammonia nitrogen online analyz...

Embodiment 3

[0058] Sewage treatment methods using on-site self-adaptive MBBR treatment devices, including:

[0059] Step 1. Water intake, which includes installing and constructing a sewage pumping device to pump sewage to be treated from a designated area (river channel); the sewage pumping device includes a lift pump, and three lift pumps can be selected, of which two are used normally and one is used as a backup.

[0060] Step 2, primary sedimentation, which includes the construction of a primary sedimentation tank to receive the sewage pumped by the lift pump; the sewage is sanded in the primary sedimentation tank; a float level controller can be installed in the primary sedimentation tank and coupled with the lift pump Linkage, so that when the liquid level reaches a certain set height, the lift pump will be automatically stopped.

[0061] Step 3, biochemical treatment, which includes building an on-site self-adaptive MBBR treatment device, introducing the sewage after the initial pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com