Equipment for hydrogen production

An equipment and hydrogen technology, applied in hydrogen/syngas production, lighting and heating equipment, hydrogen, etc., can solve the problems of resource waste and insufficient energy utilization, save production costs, facilitate separation and purification, and avoid leakage and waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

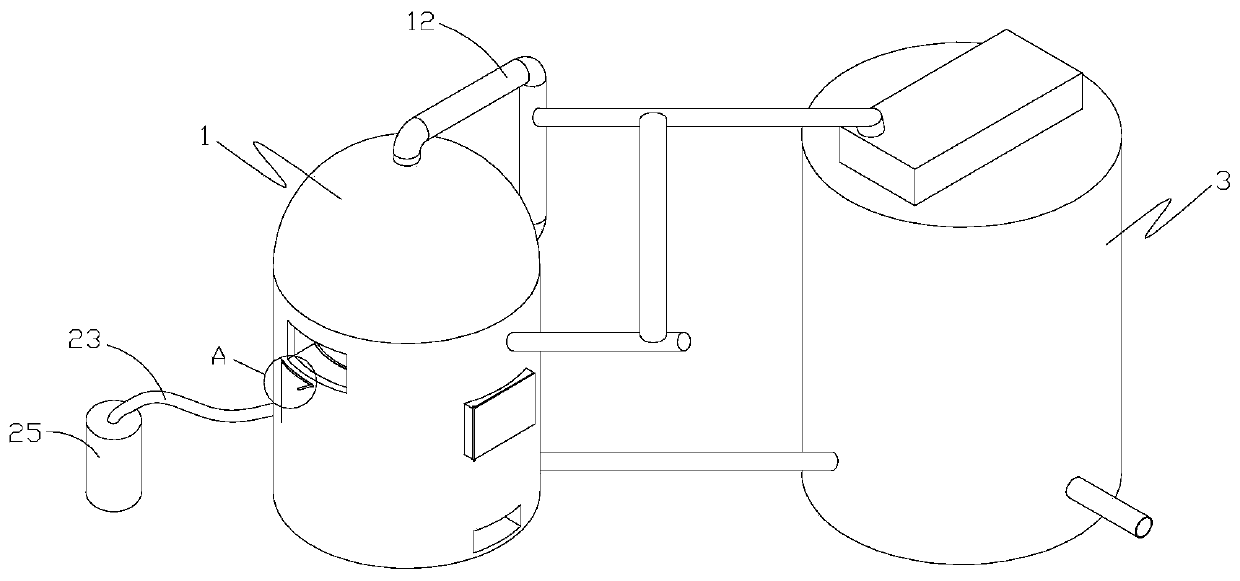

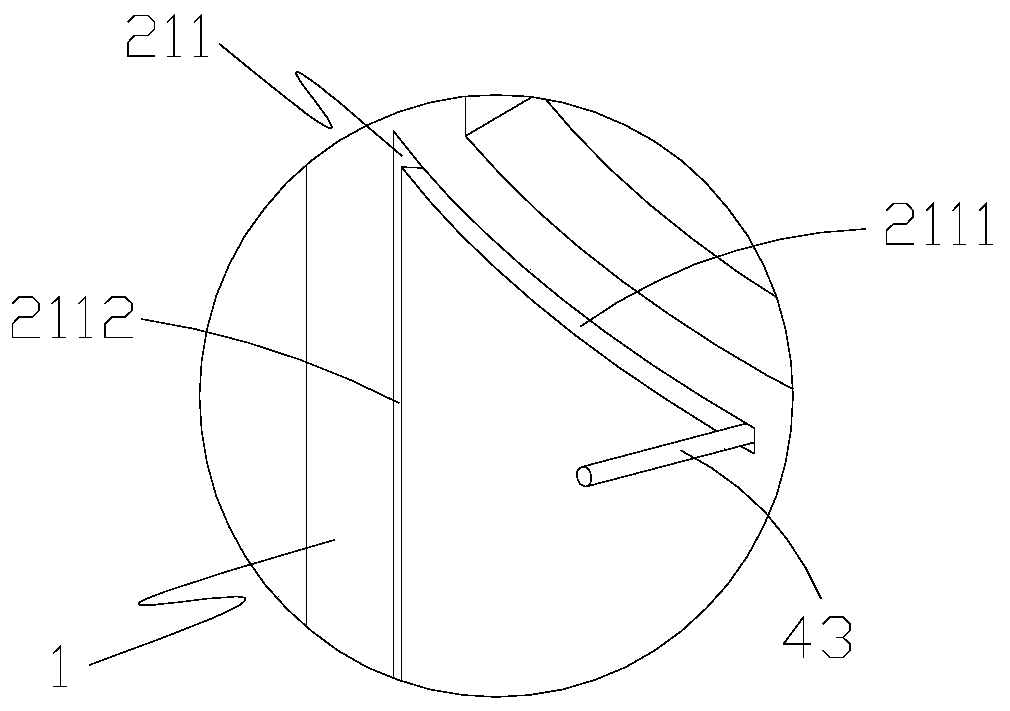

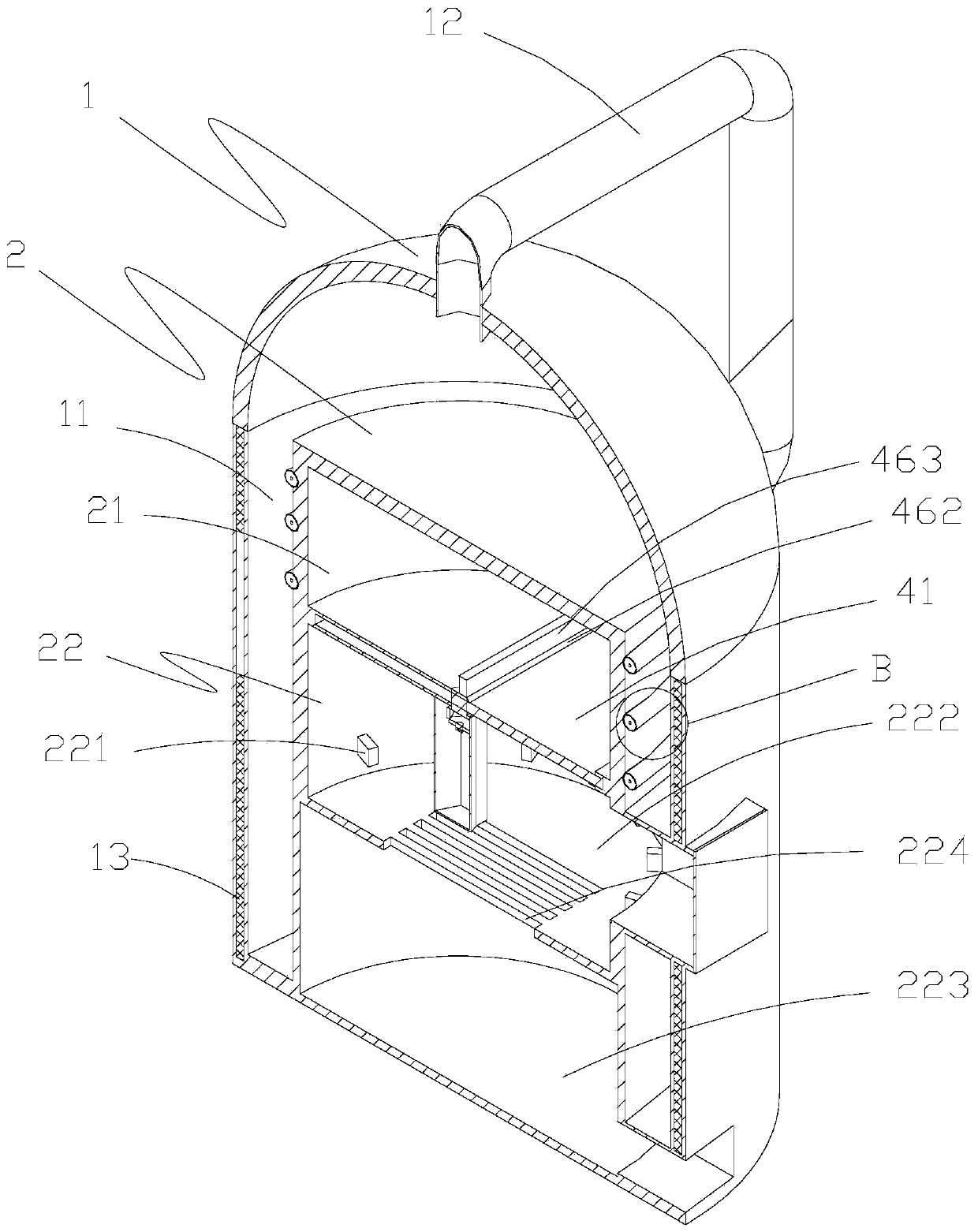

[0027] Such as Figure 1-14 Shown, a kind of equipment for hydrogen production comprises steam boiler 1, reaction furnace 2 and purification furnace 3; steam boiler comprises steam chamber 11, steam pipe 12 and auxiliary heating device; The reaction furnace is basically surrounded, so that the reaction furnace can directly heat the steam chamber, the heating efficiency is high, the heat loss is small, and the equipment occupies a smaller area; the reaction furnace includes a reaction chamber 21, a heating chamber 22 and a switch device; the reaction chamber and the steam chamber Closely attached, the heating chamber is installed under the reaction chamber and is close to the reaction chamber, so that the heating chamber can directly heat the reaction chamber; in order to better introduce the heat in the heating chamber into the reaction chamber and the steam chamber, the A plurality of heat conduction fins 221 are installed on the inner wall. One end of the heat conduction fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com