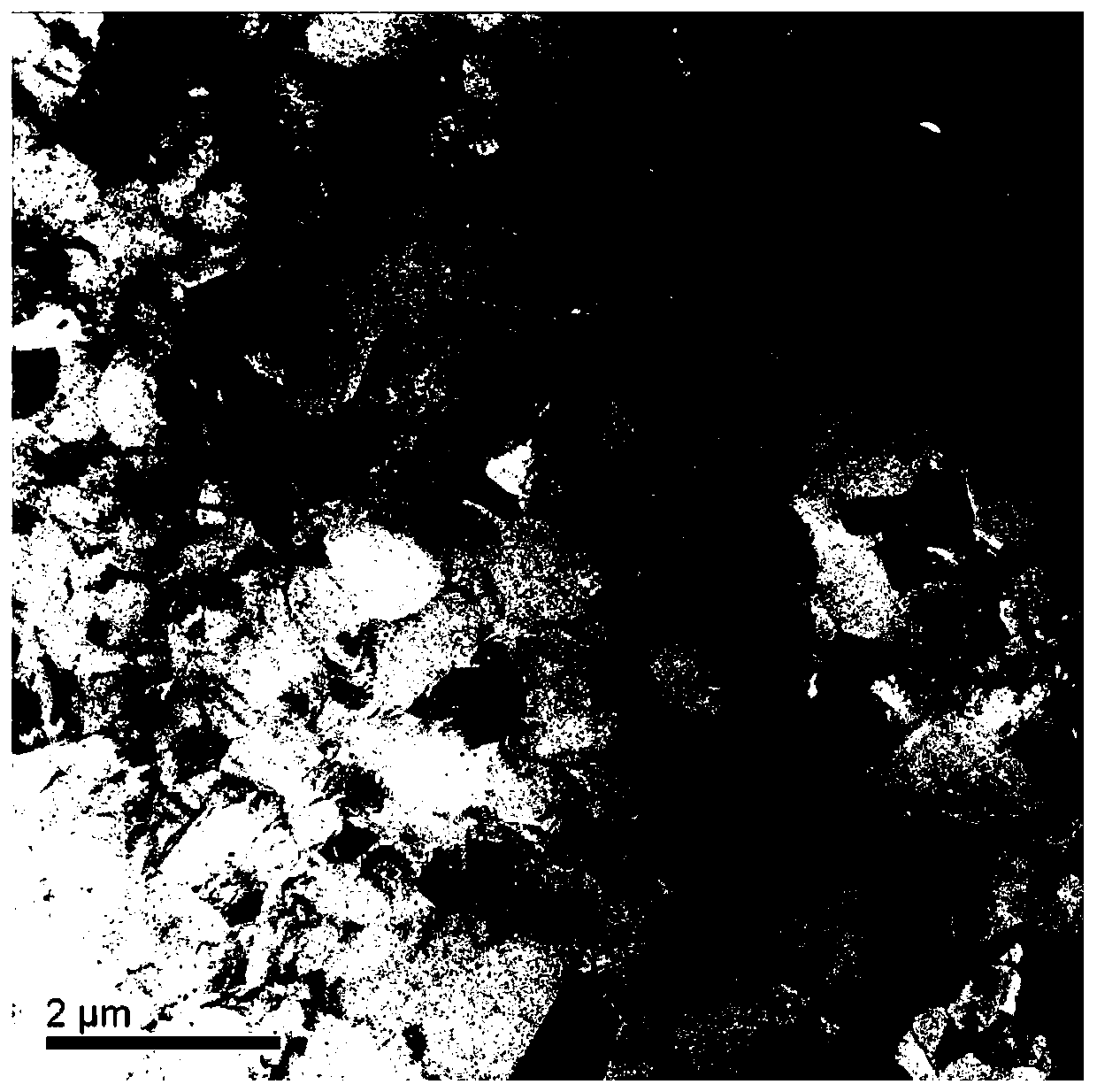

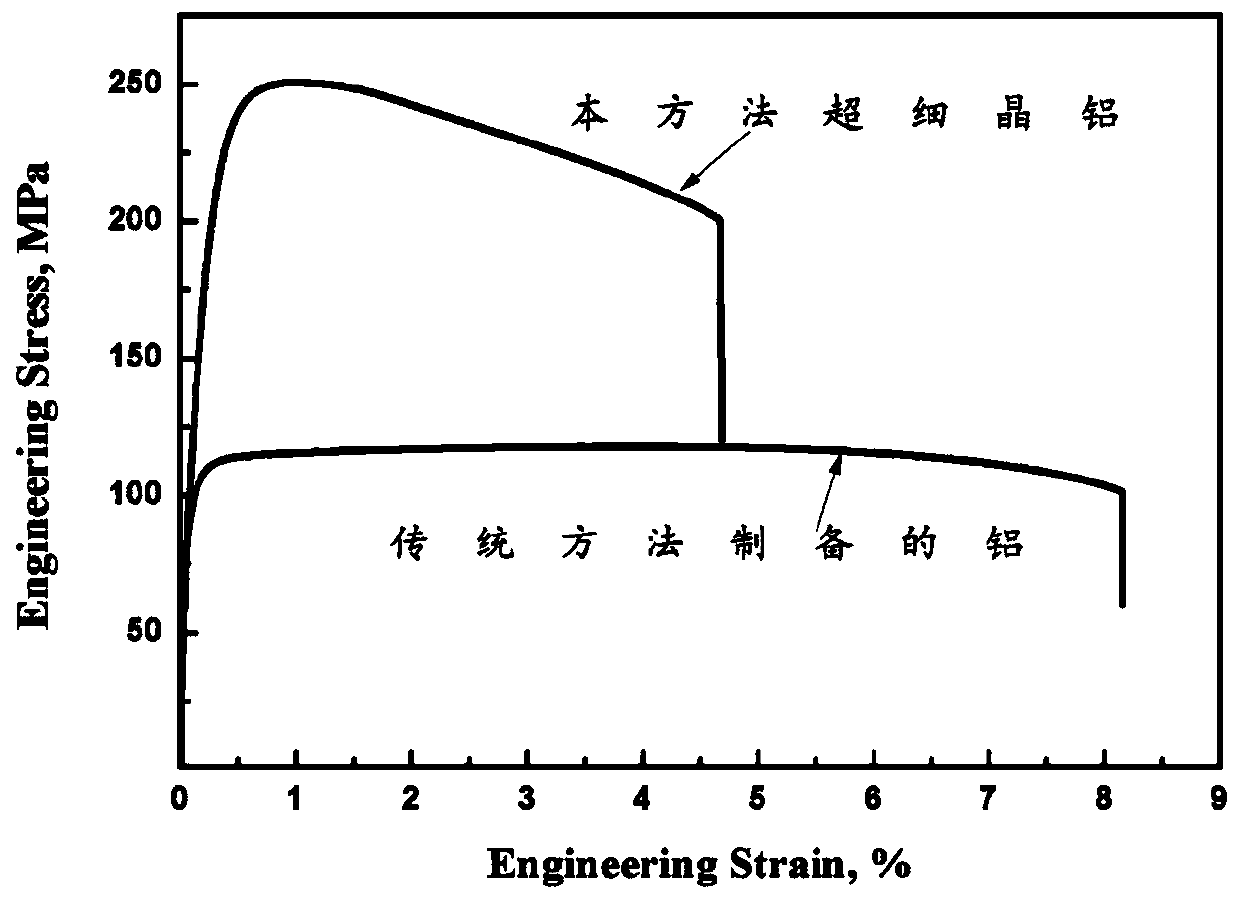

Preparation method of high-strength and high-toughness thin strip aluminum of ultra-fine structure

A fine-structure, high-strength technology, applied in metal rolling, manufacturing tools, temperature control, etc., can solve the problems of complex ultra-fine-grained or nano-crystalline aluminum alloy process, difficult industrial application, and limited product size, so as to facilitate industrial application , low manufacturing cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Taking the ordinary aluminum ingot in the industrial solid solution state as the initial material, the aluminum ingot may contain Si, Mn, Fe, Cu, Mg, Ti, Cr alloy elements and inevitable impurities, each of which is The mass percentage content does not exceed 1.0%, and the total amount of elements does not exceed 2.5%. The steps for preparing ultra-fine structure high-strength aluminum ribbon are as follows:

[0035] Step (1) Homogenization treatment: After sawing and milling the above aluminum casting billet or aluminum ingot, it is placed in a heat treatment furnace at 500°C for 7.0 hours to obtain a base material with homogeneous structure and properties for later rolling .

[0036] Step (2) Rough rolling: After cleaning the surface of the homogeneous aluminum cast slab, perform hot rolling, the hot rolling start-up temperature is 500°C, the final rolling temperature is 450°C, and the final rolling thickness is controlled at 20mm;

[0037] Step (3) Strong shear deformation...

Embodiment 2

[0042] Taking the ordinary aluminum ingot in the industrial solid solution state as the starting material, the mass percentage of Si, Mn, Fe, Cu, Mg, Ti, Cr and other alloying elements and inevitable impurities in the aluminum ingot shall not exceed 2.5%, The mass percentage content of each element does not exceed 0.5%. The steps for preparing ultra-fine structure high-strength aluminum ribbon are as follows:

[0043] Step (1) Homogenization treatment: After sawing and milling the above aluminum casting billet or aluminum ingot, it is placed in a heat treatment furnace at 580°C for 2.0 hours to obtain a base material with homogeneous structure and properties.

[0044] Step (2) Rough rolling: After cleaning the surface of the homogeneous aluminum cast slab, perform hot rolling, the hot rolling start-up temperature is 580°C, the final rolling temperature is 480°C, and the final rolling thickness is controlled at 20mm;

[0045] Step (3) Strong shear deformation rolling: rough-rolled alu...

Embodiment 3

[0050] Taking the ordinary aluminum ingot in the industrial solid solution state as the starting material, the mass percentage of Si, Mn, Fe, Cu, Mg, Ti, Cr and other alloying elements and inevitable impurities in the aluminum ingot shall not exceed 1.5%, The mass percentage content of each element does not exceed 0.3%. The steps for preparing ultra-fine structure high-strength aluminum ribbon are as follows:

[0051] Step (1) Homogenization treatment: After sawing and milling the aluminum casting billet or aluminum ingot, it is placed in a 450°C heat treatment furnace for 15.0 hours to obtain a base material with homogeneous structure and properties for later rolling.

[0052] Step (2) Rough rolling: After cleaning the surface of the homogeneous aluminum cast slab, perform hot rolling, the hot rolling start-up temperature is 450°C, the final rolling temperature is 430°C, and the final rolling thickness is controlled at 15mm;

[0053] Step (3) Strong shear deformation rolling: rough-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com