Shield type liquid pump

A liquid pump and shielding technology, which is applied to liquid fuel engines, pumps, components of pumping devices for elastic fluids, etc., can solve the problems of sealing attenuation, potting failure, potting material aging, etc., to meet the requirements of Long life, the effect of solving the problem of low reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the drawings and specific embodiments:

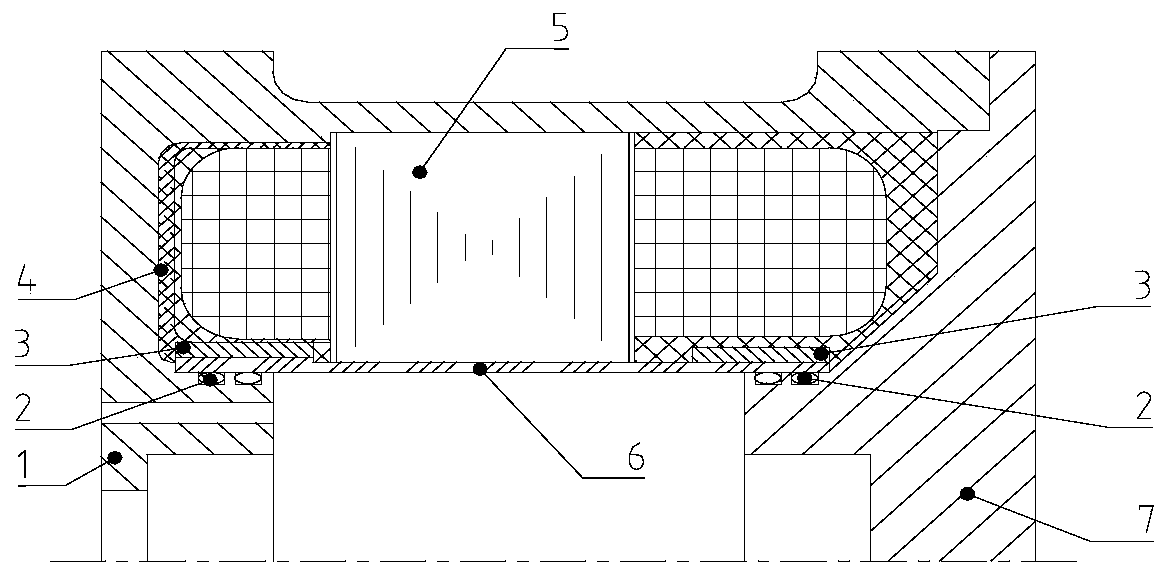

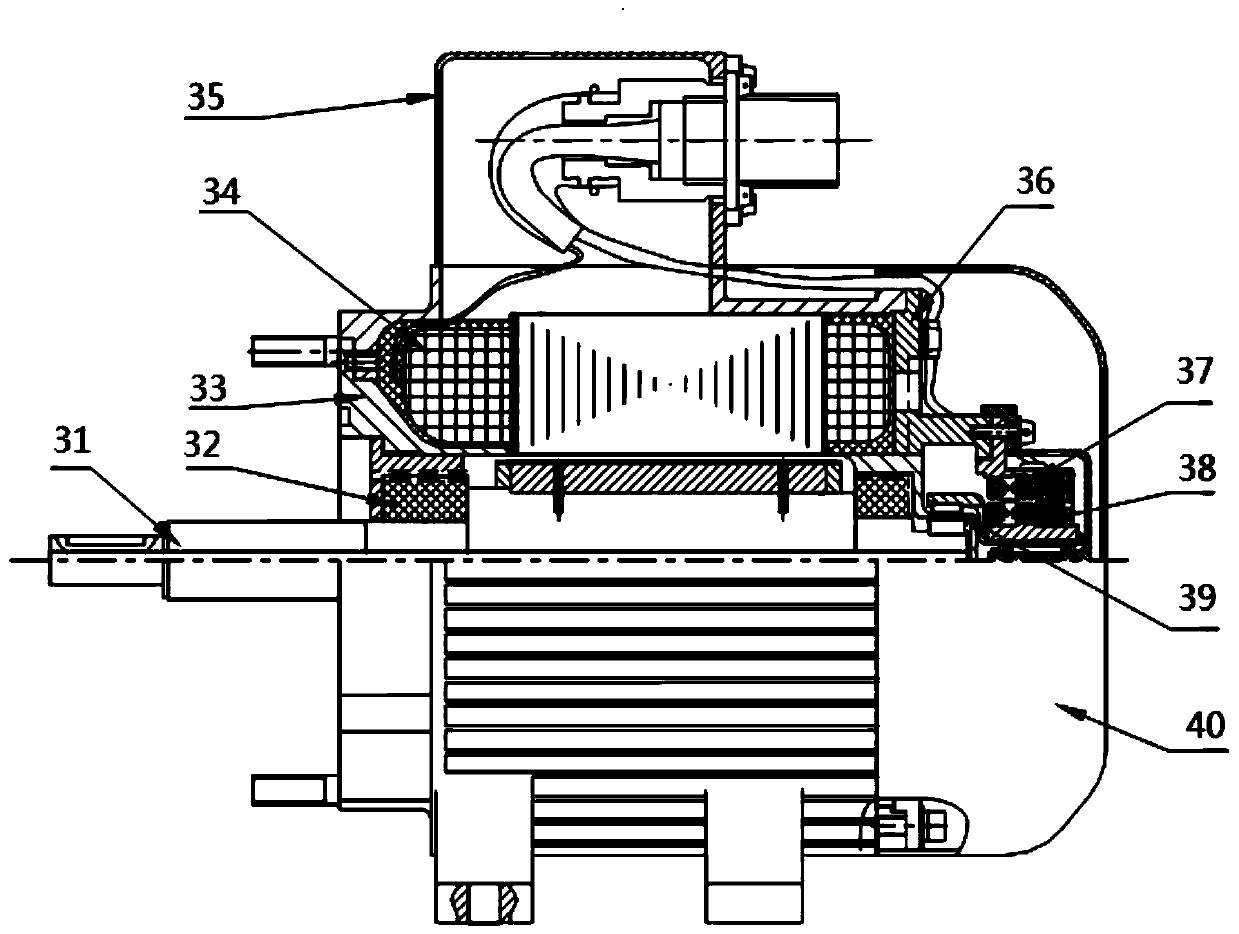

[0013] A high-reliability liquid-cooled pump with a shielded structure, which is composed of a pump body and a motor. figure 2 As shown, it is composed of impeller, liquid inlet, volute, etc., canceling the dynamic seal structure of the original product; the structure diagram of the motor part is as follows image 3 As shown, it is composed of rotor, graphite bearing, end cover, stator, socket, resolver, magnetic gear and other structures. The motor part has a liquid inlet at the motor port, and the coolant enters the motor, and then flows out of the motor shaft. The stator is vacuum potted and protected with a metal sheath to isolate the coolant from the stator to realize the coolant inside the motor Liquid feed structure for circulation.

[0014] A shielded liquid pump, including a pump body and a motor, is characterized in that: a liquid inlet is opened at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com