Gradient utilization enhanced hot dry rock geothermal system

A hot dry rock, enhanced technology, applied in the field of enhanced hot dry rock geothermal system, can solve the problems of low utilization rate and poor stability of the geothermal system, avoid damage to pipelines and heat exchange devices, reduce energy waste, and improve utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

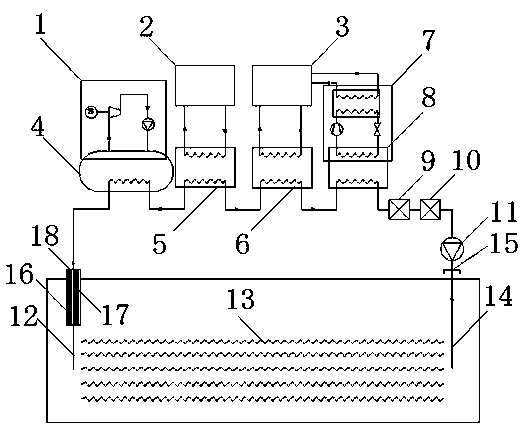

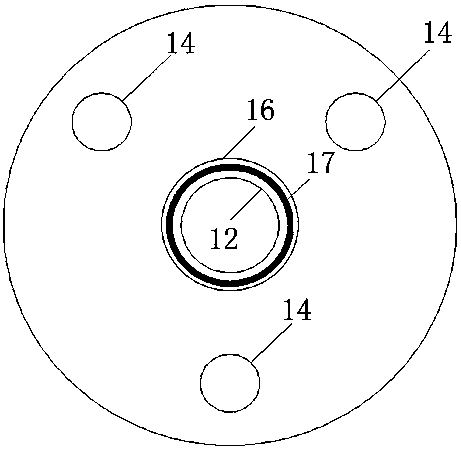

[0020] Embodiment 1, a kind of enhanced hot dry rock geothermal system of cascade utilization, such as figure 1 As shown, it includes the production well pipeline 12 and the reinjection well pipeline 14 connected with the underground hot dry rock. The production well pipeline 12 and the reinjection well pipeline 14 are connected or hydraulically fractured in the dry hot rock formation through the formation of the pipeline or through the formation void connection. The connection realizes communication, and the artificial heat reservoir 13 of low hot dry rock is established. The clean water source is used as the heating medium to inject into the reinjection well pipeline 14, and the working medium exchanges energy with the high-temperature rock mass in the hot dry rock artificial thermal reservoir 13, and then is extracted from the well for utilization.

[0021] The production well pipeline 12 and the reinjection well pipeline 14 are sequentially connected with a first-stage pla...

Embodiment 2

[0025] Embodiment 2, a kind of enhanced hot dry rock geothermal system of cascade utilization, such as figure 2 As shown, there is one production well pipeline 12 and at least two reinjection well pipelines 14 . The water injection pump 11 is arranged between the water return end of the three-stage plate heat exchanger 6 and the water separator 15 , and the water injection pump 11 can be used to pump water to multiple recharge well pipes 14 .

[0026] The method of multiple reinjection well pipelines 14 and one or a small number of production well pipelines 12 effectively avoids the shortcoming of unstable system operation for a period of time, and multiple reinjection well pipelines can be selected to be used at the same time or only through the water divider 15 one.

[0027] Other structures of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0028] Embodiment 3, an enhanced hot dry rock geothermal system for cascade utilization, a four-stage plate heat exchanger 8 is arranged between the three-stage plate heat exchanger 6 and the reinjection well pipeline 14, through which the four-stage plate heat exchanger The device 8 makes full use of the 40°C-45°C working fluid from the three-stage plate heat exchanger 6.

[0029] The heat exchange end of the four-stage plate heat exchanger 8 is connected with a heat pump unit 7 , and the heat pump unit 7 is connected with the radiant heating module 3 . The heat energy generated by the four-stage plate heat exchanger 8 and the heat energy generated by the heat pump unit 7 work together to provide auxiliary heat to the radiant heating module 3 to prevent the situation that the three-stage plate heat exchanger 6 cannot meet the normal use of the radiant heating module 3 .

[0030]The water separator 15 is arranged between the return water end of the four-stage plate heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com