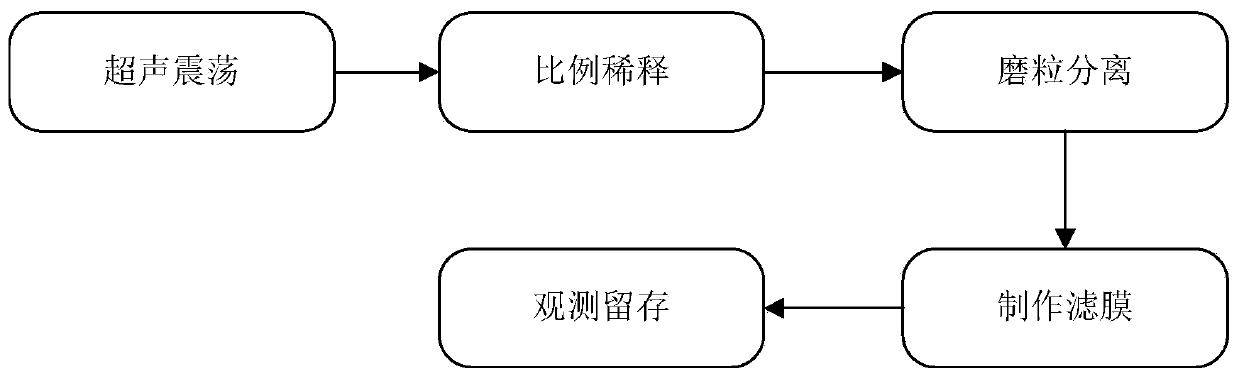

Offline abrasive particle extraction method

An extraction method and technology of abrasive particles, applied in sampling, particle and sedimentation analysis, preparation of test samples, etc., can solve problems such as inaccurate analysis of abrasive particles, achieve convenient research, ensure observation effect, and reduce stacking phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

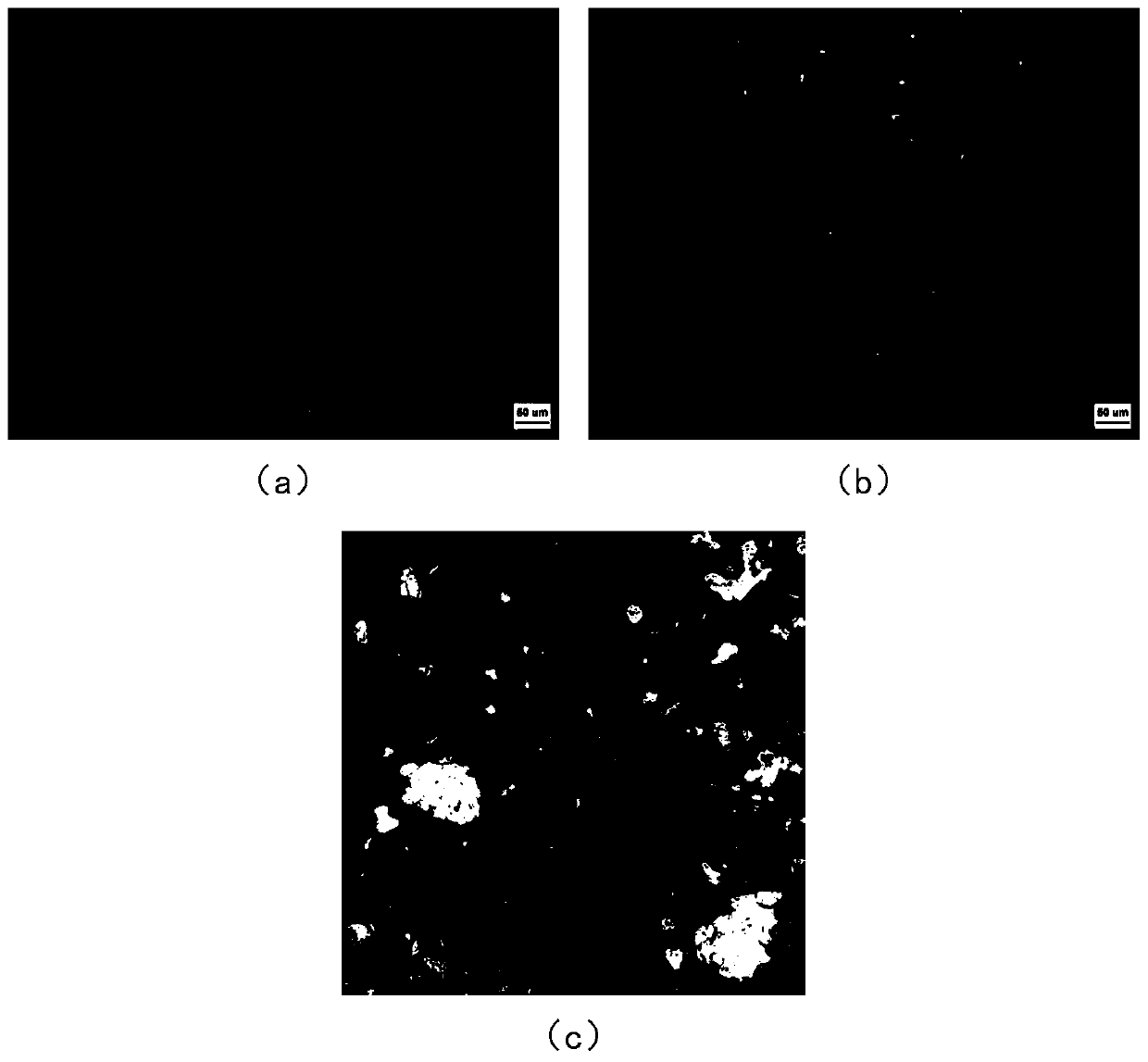

[0028] For off-line abrasive particle extraction methods, figure 2 (a) It clearly shows that white products appear in the samples under the clear solutions of various concentrations at 30°C, such as image 3 As shown in (a), this is caused by the dissolution of the filter membrane by the clear solution of N-methylpyrrolidone, and the filter membrane on each sample slide has cracked and peeled, as shown in image 3 As shown in (b), these white formations, cracking and peeling have seriously affected the observation and study of abrasive particles on the filter membrane of the slide in the sample. And during the experiment, because the constant temperature platform at 30°C is basically at room temperature, it is similar to placing the slide and filter membrane directly at room temperature for normal temperature drying. It can be seen from the experimental results that when the temperature is 30°C, each concentration None of them can be successfully made into fragment slide sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com