Catalytic combustion type MEMS gas sensor and working method thereof

A gas sensor, catalytic combustion technology, applied in the field of sensors, can solve problems such as poor safety and poor temperature isolation structure, and achieve the effects of low cost, fast response time and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

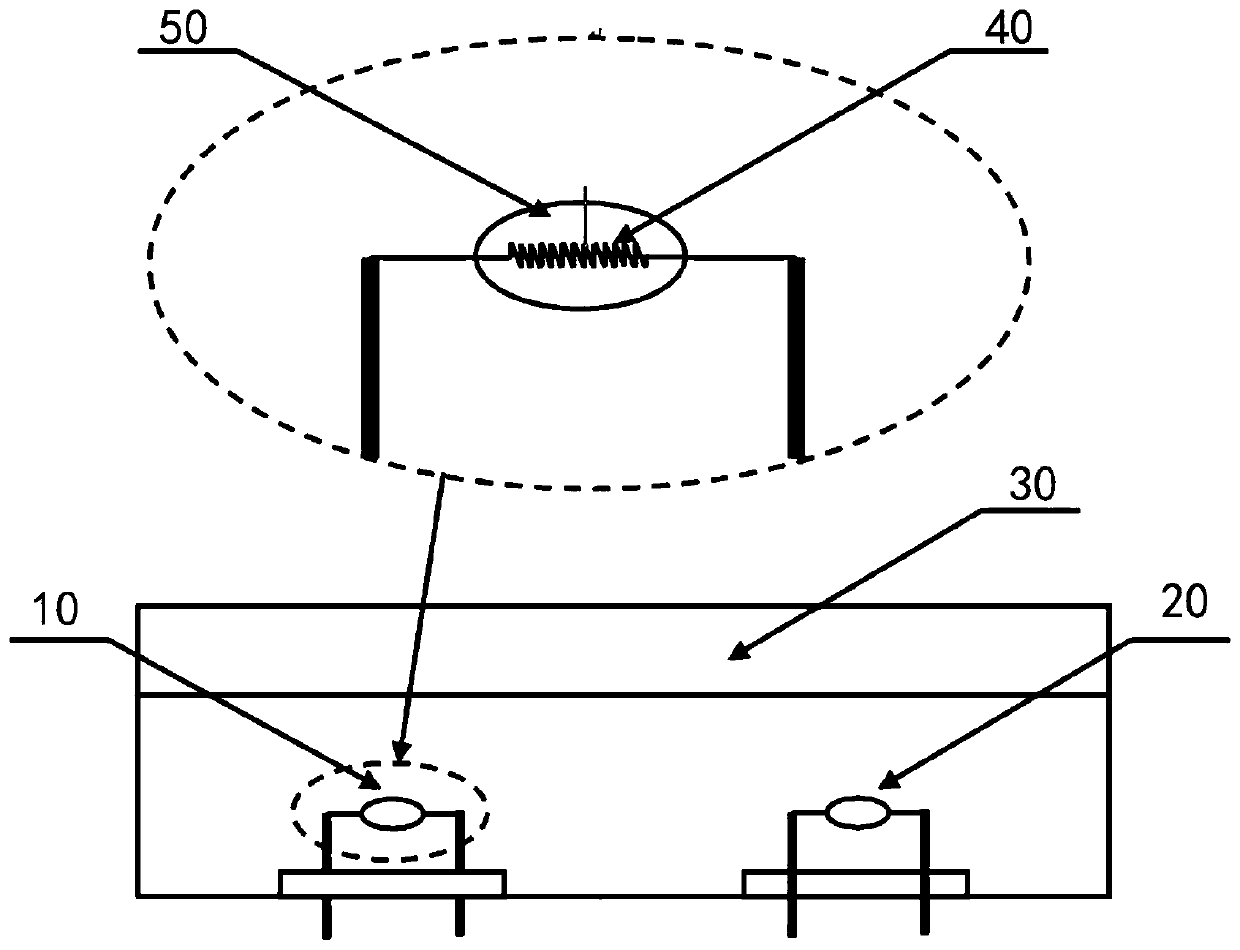

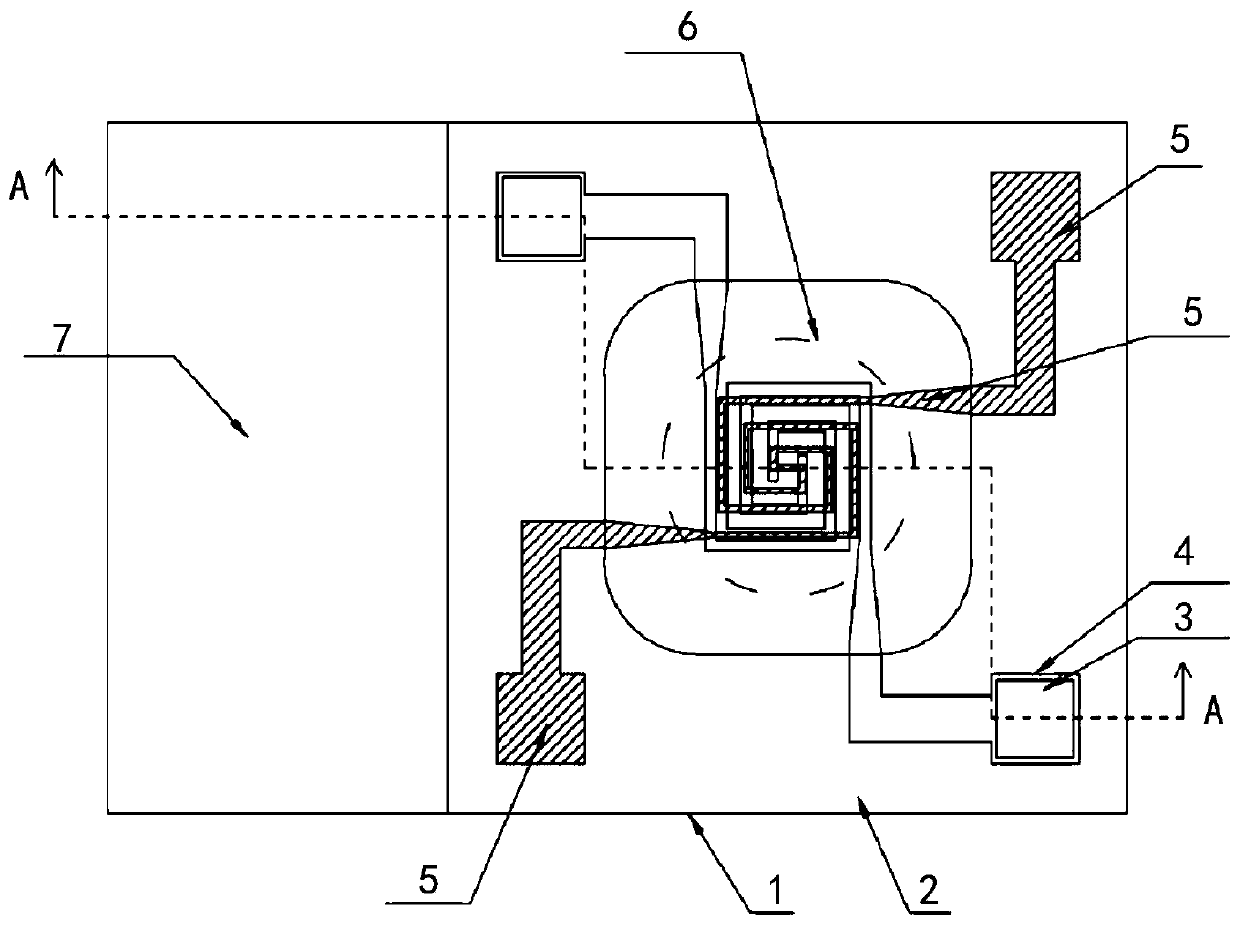

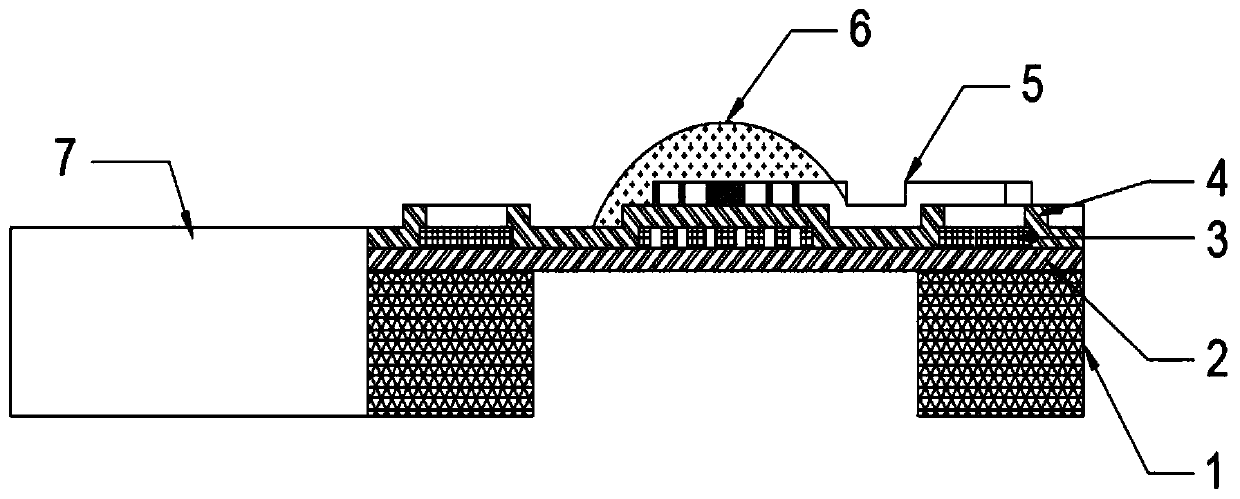

[0028] See figure 2 and image 3 The embodiment of the present invention provides a catalytic combustion type MEMS gas sensor, which includes a substrate 1, a first insulating support layer 2, a resistance heating layer 3, a second insulating support layer 4, a temperature sensing electrode layer 5, and a catalytic material layer 6 and microcontroller 7. The first insulating support layer 2 is arranged on the substrate 1, the resistance heating layer 3 is arranged on the first insulating support layer 2, and the second insulating support layer 4 covers the resistance heating layer 3; the temperature sensing electrode layer 5 is arranged on the On the second insulating support layer 4, the catalytic material layer 6 is attached to the temperature sensing electrode layer 5 and the upper part of the heating work area of the second insulating support layer 4. The microcontroller 7 is arranged on the substrate 1, and the microcontroller 7 is electrically connected to the heating ...

Embodiment 2

[0038] See figure 2 and image 3 The embodiment of the present invention provides a working method of a catalytic combustion type MEMS gas sensor, wherein the working temperature of the MEMS gas sensor is 100-600°C. The method includes the following steps:

[0039] Step S10, the control microcontroller 7 measures the resistance values of the heating resistance layer 3 and the temperature sensing electrode layer 5, and obtains the heating power and heating temperature of the heating resistance layer 3 and the temperature sensing electrode layer 5.

[0040] Among them, the resistance value of the resistance heating layer 3 is Rh, the power supply voltage is VCC, the heating power is controlled by PWM, and the PWM duty cycle Duty is D, then the heating power P is:

[0041] P=D*VCC / Rh 2 ;

[0042] The resistance of the temperature-sensing electrode layer is Rs, the temperature coefficient of the temperature-sensing electrode material is K, and the resistance of the temperature-sensing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com