Compact Airy beam phase plate and manufacturing method thereof

An Airy beam and manufacturing method technology, applied in the field of information optics, can solve problems such as difficult miniaturization, and achieve the effects of easy miniaturization and integration, compact structure, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

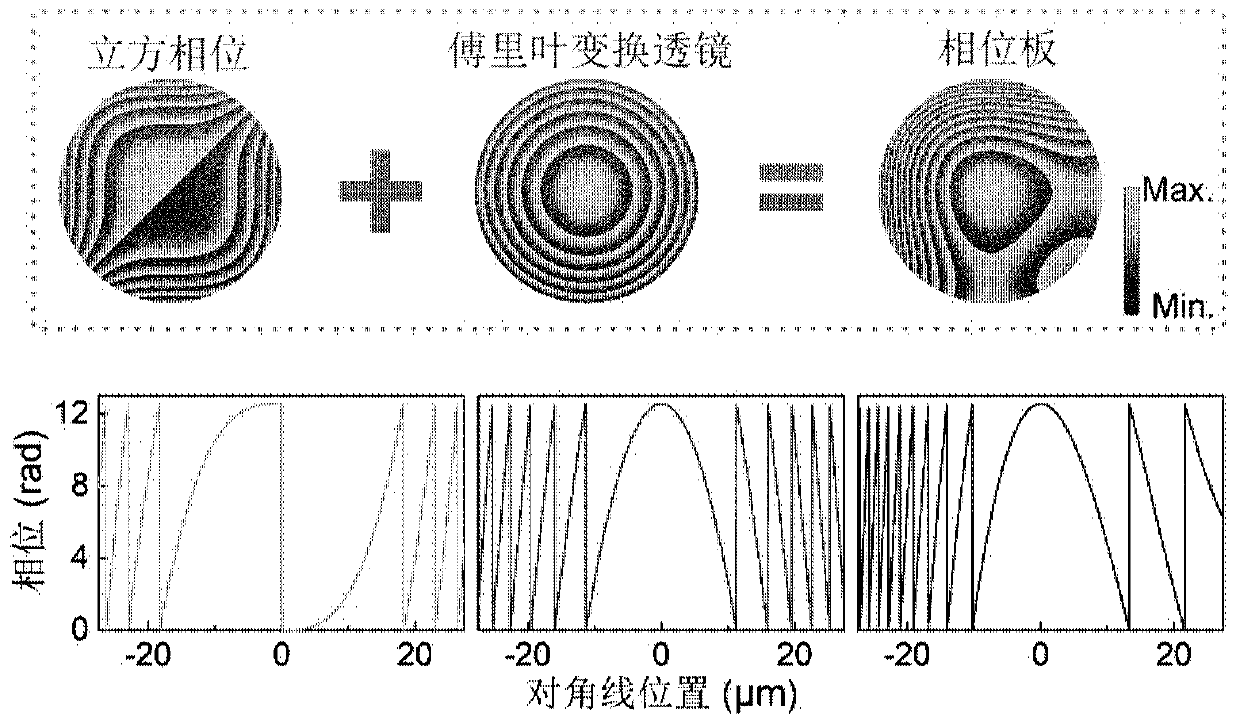

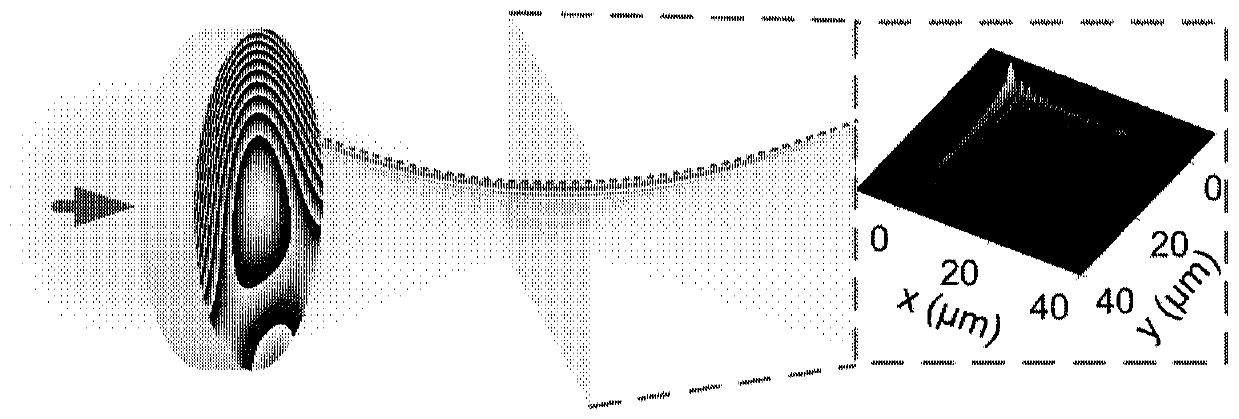

Method used

Image

Examples

Embodiment 1

[0049] According to the design of the present invention, the cubic phase constant k can be produced 0 Airy phase plate of 7 μm and lens focal length f of 60 μm, such as Figure 4 shown. The manufactured Airy phase plate can be prepared by femtosecond laser direct writing three-dimensional processing technology. In order to ensure a good processing effect, a cylindrical base with a thickness of 2 μm is added to the bottom of the phase plate to compensate for the initial position error of the z-direction processing;

[0050]Based on the manufacturing of the phase plate of the present invention, different phase modulation depths can be manufactured for different laser light source wavelengths and materials. In Example 1, the green light source with a wavelength of 532nm is manufactured, the maximum phase modulation depth is 4π, and the refractive index of the polymer material used is 1.505, therefore, the maximum height of the phase plate fringes is 2.11 μm.

Embodiment 2

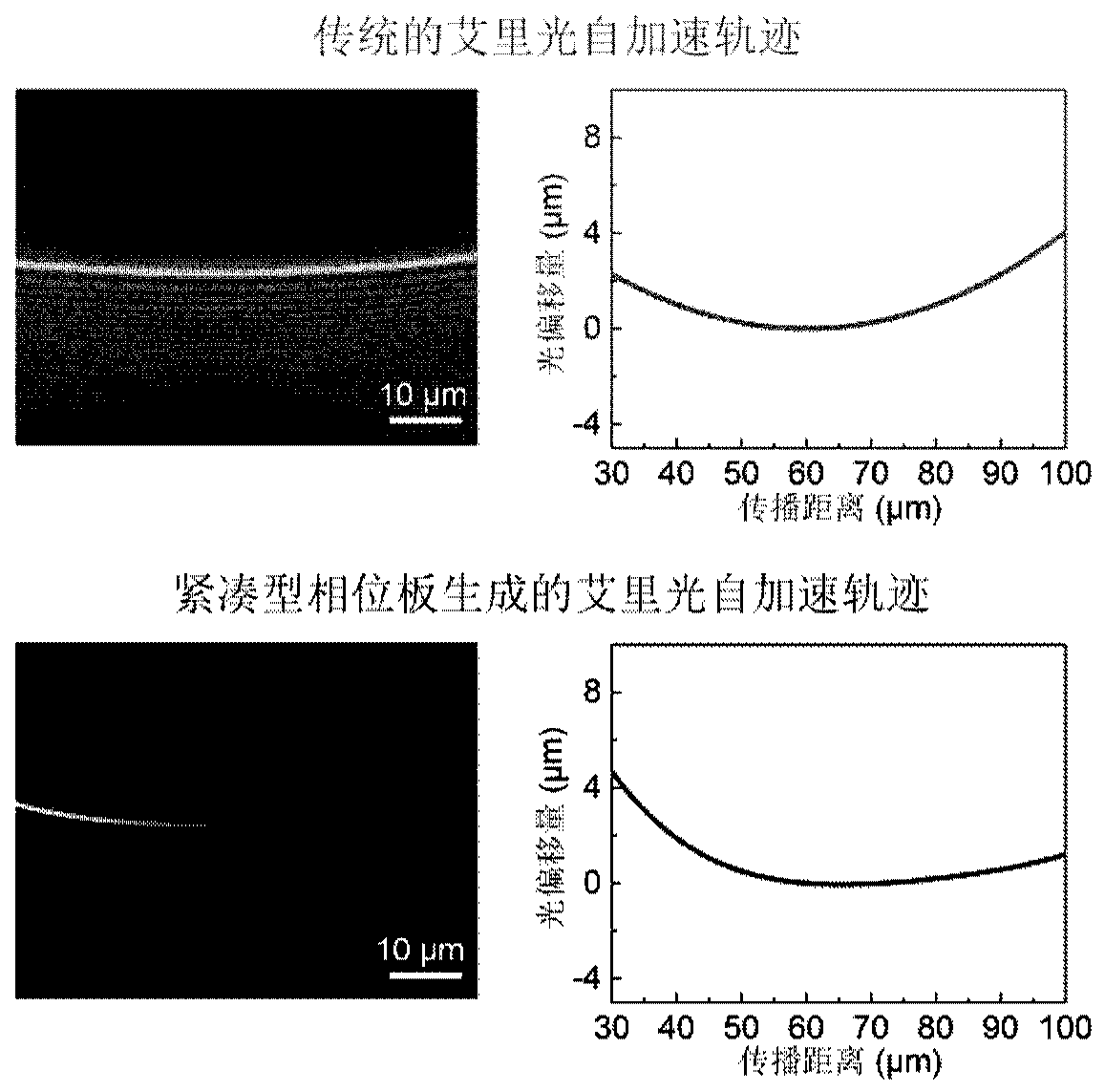

[0052] In the manufacturing method of the phase plate in the present invention, both characteristic parameters can be adjusted freely, so as to generate Airy beams with different characteristics. for k 0 = 7.5 μm, f = 60 μm, k 0 = 7.5 μm, f = 50 μm and k 0 = 9.5 μm, f = 40 μm three parameters of phase plate manufacturing and femtosecond laser three-dimensional processing effect as follows Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com