Intelligent inspection system and method for secondary equipment of 500kV transformer substation

A technology of intelligent inspection and secondary equipment, applied in information technology support systems, electrical components, circuit devices, etc., can solve problems such as wrong switching of soft press plates, and achieve reasonable structure, convenient use, and good cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

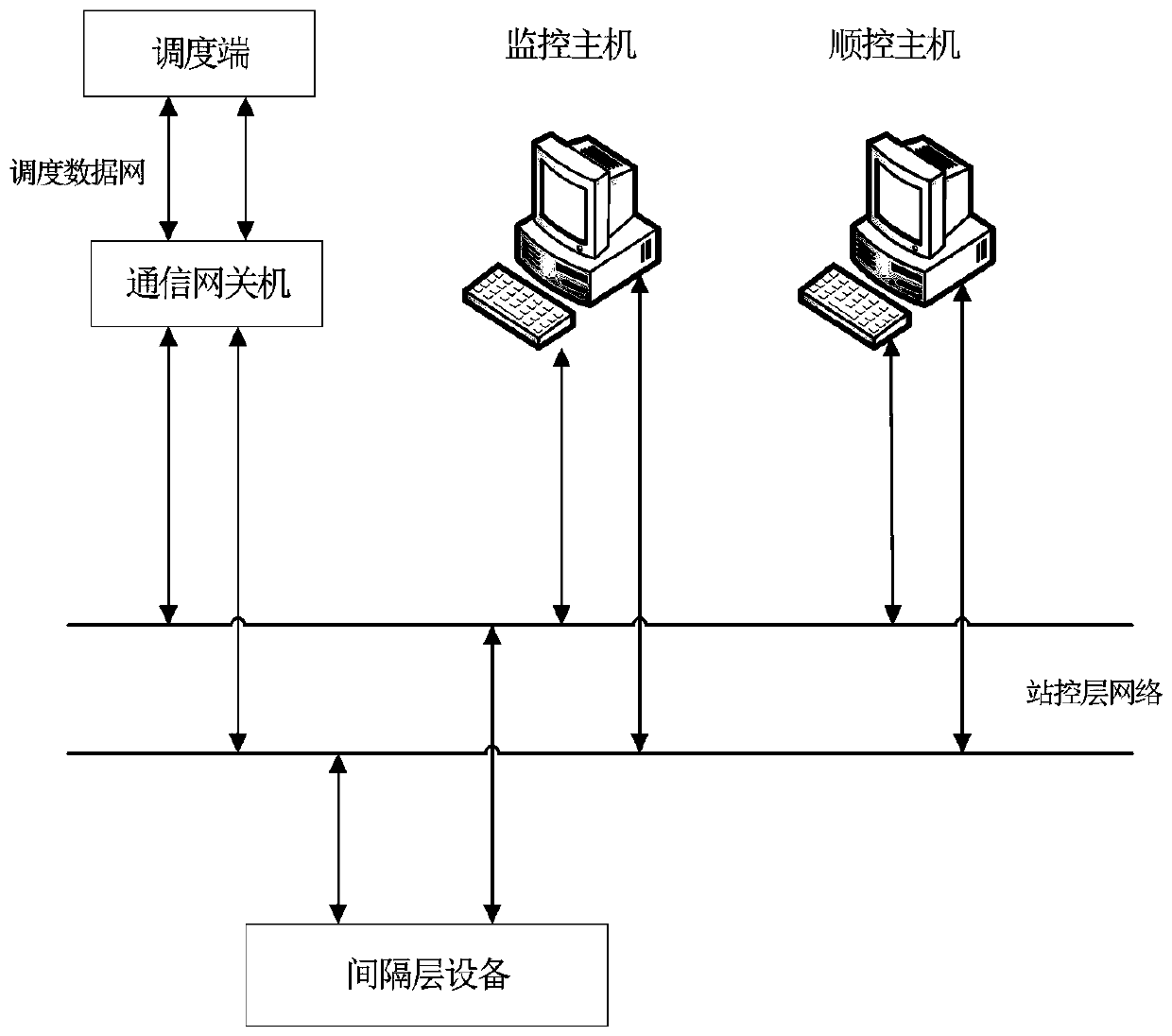

[0049] Such as figure 1 As shown, the present invention discloses an intelligent inspection system for secondary equipment in a 500kV substation, including a monitoring host, a dispatching terminal, a communication gateway, a station control layer network, an interval layer device, a sequence control host, and an inspection module. The monitoring host It is connected to the station control layer network and communicates bidirectionally. The dispatcher is connected to the communication gateway machine and communicates bidirectionally. The communication gateway machine is connected to the station control layer network and communicates bidirectionally. The station control layer network is connected to the interval layer equipment and Bi-directional communication, the sequence control host is connected to the station control layer network and communicates bi-directionally.

[0050] The sequence control host is placed in the protection chamber and conducts human-computer interactio...

Embodiment 2

[0055] Such as figure 2 , image 3 As shown, the present invention discloses an intelligent inspection method for secondary equipment in a 500kV substation, including S1 soft pressing plate one-button sequential control, S2 pressing plate intelligent inspection, S3 monitoring optical word intelligent inspection, S4 pressing plate anti-error locking management and S5 The biometric steps are as follows:

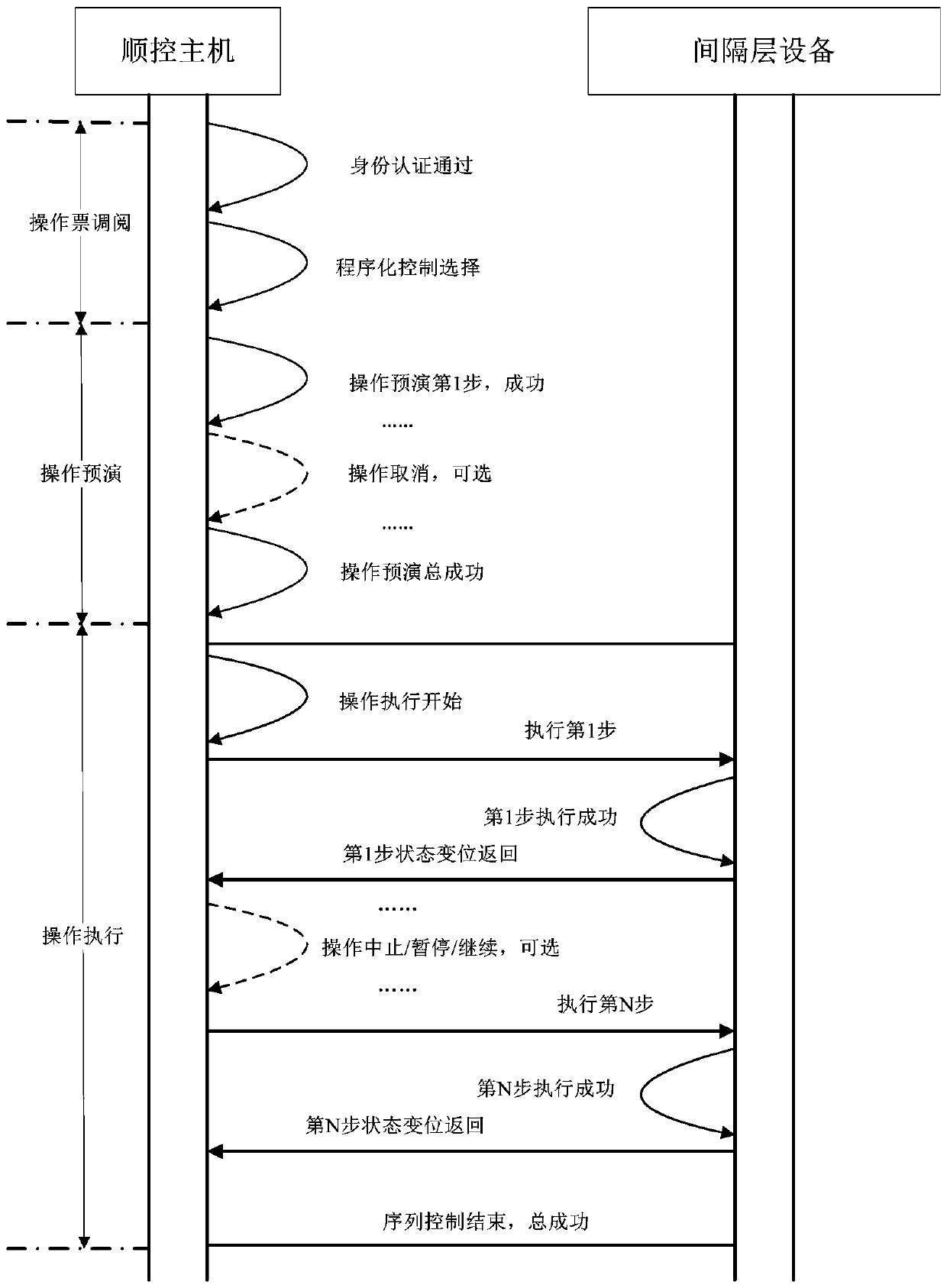

[0056] S1 soft platen one-button sequential control

[0057] Such as figure 2 As shown, the sequence control host initiates the station-side programmed control, and the steps include S1.1 operation ticket retrieval, S1.2 operation rehearsal and S1.3 operation execution, a total of three steps. During the process, the operation is canceled and the operation is suspended. , operation continuation and operation termination for manual intervention.

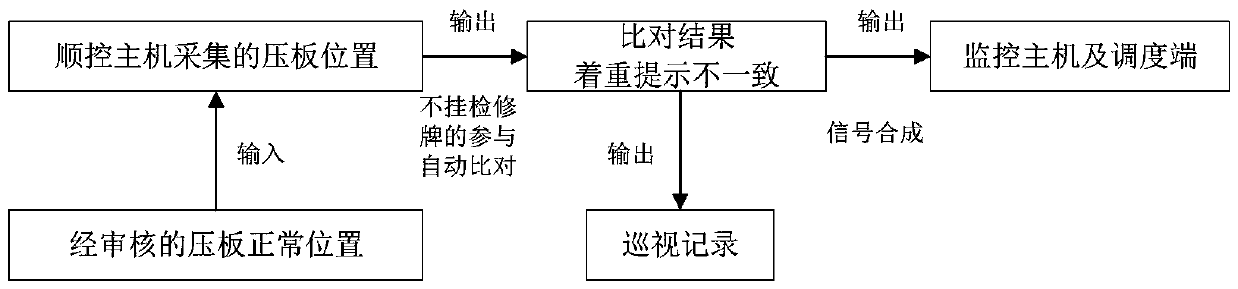

[0058] S2 inspection platen

[0059] S2.1 Arrangement rules of pressure plate

[0060] Use color to distinguish the sequence ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com