Aluminum hydroxide adjuvant and preparation method and application thereof

A technology of aluminum hydroxide and sodium hydroxide, applied in the direction of pharmaceutical formulations, medical preparations containing active ingredients, antibody medical ingredients, etc., can solve the problem of affecting the adsorption rate and sedimentation rate of adjuvants, high equipment and energy requirements, high temperature repeated Dealing with and other issues to achieve the effects of reducing production costs, reducing energy consumption, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

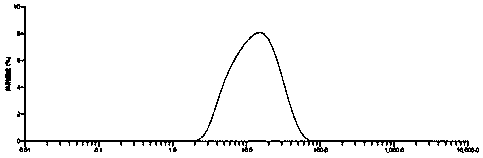

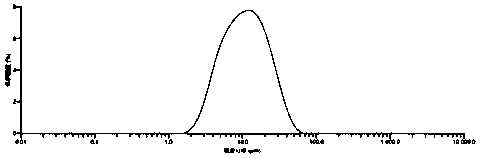

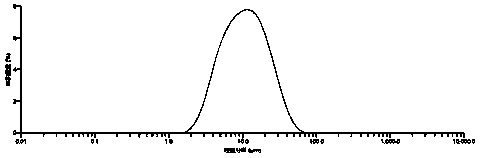

Image

Examples

Embodiment 1

[0043] Weigh disodium hydrogen phosphate, sodium dihydrogen phosphate monohydrate and sodium chloride and dissolve them in water for injection, adjust the pH to 7.0, filter and subpackage to obtain pH7.0 phosphate buffer; weigh KAl(SO 4 )·12H 2 O was dissolved in water for injection, sterile filtered and subpackaged to obtain a 0.21mol / L aluminum potassium sulfate solution; weighed sodium hydroxide was dissolved in water for injection, sterile filtered and subpackaged to obtain a 0.5mol / L sodium hydroxide solution. Prepare tanks for CIP and SIP, and cool to 2-8°C under temperature control.

[0044] Add 160kg pH7.0 phosphate buffer solution into the preparation tank, stir at 80rpm, add 56.5kg of 0.21mol / L aluminum potassium sulfate solution at a speed of 4kg / min, and add 0.5mol / L sodium hydroxide at a speed of 4.0kg / min Solution 54.5kg; adjust the pH to 6.5-7.2, and continue stirring for no less than 30 minutes.

[0045] After standing under controlled pressure, remove the su...

Embodiment 2

[0050] Weigh disodium hydrogen phosphate, sodium dihydrogen phosphate monohydrate and sodium chloride and dissolve them in water for injection, adjust the pH to 7.0, filter and subpackage to obtain pH7.0 phosphate buffer; weigh KAl(SO 4 )·12H 2O was dissolved in water for injection, sterile filtered and subpackaged to obtain a 0.21mol / L aluminum potassium sulfate solution; weighed sodium hydroxide was dissolved in water for injection, sterile filtered and subpackaged to obtain a 0.5mol / L sodium hydroxide solution. Prepare tanks for CIP and SIP, and cool to 2-8°C under temperature control.

[0051] Add 170kg pH7.0 phosphate buffer solution into the preparation tank, stir at 80rpm, add 60kg of 0.21mol / L aluminum potassium sulfate solution at a speed of 3.9kg / min, and add 0.5mol / L sodium hydroxide solution at a speed of 4kg / min 58kg; adjust the pH to 6.5-7.2, and continue stirring for no less than 30 minutes.

[0052] After standing under controlled pressure, remove the superna...

Embodiment 3

[0057] Weigh disodium hydrogen phosphate, sodium dihydrogen phosphate monohydrate and sodium chloride and dissolve them in water for injection, adjust the pH to 7.0, filter and subpackage to obtain pH7.0 phosphate buffer; weigh KAl(SO 4 )·12H 2 O was dissolved in water for injection, sterile filtered and subpackaged to obtain a 0.21mol / L aluminum potassium sulfate solution; weighed sodium hydroxide was dissolved in water for injection, sterile filtered and subpackaged to obtain a 0.5mol / L sodium hydroxide solution. Prepare tanks for CIP and SIP, and cool to 2-8°C under temperature control.

[0058] Add 170kg pH7.0 phosphate buffer solution into the preparation tank, stir at 80rpm, add 60kg of 0.21mol / L aluminum potassium sulfate solution at a speed of 6.1kg / min, and add 0.5mol / L sodium hydroxide solution at a speed of 4kg / min 58kg; adjust the pH to 6.5-7.2, and continue stirring for no less than 30 minutes.

[0059] After standing under controlled pressure, remove the supern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com