2000 aluminum alloy profile and manufacturing method thereof

A technology for an aluminum alloy profile and a manufacturing method, applied in the field of aluminum profiles, can solve the problems of deterioration of external appearance, occurrence of orange peel, rough recrystallized structure, etc., and achieve the effects of excellent bendability, simplified manufacturing process, and reduced manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for manufacturing a 2000 aluminum alloy profile, comprising the following steps in sequence:

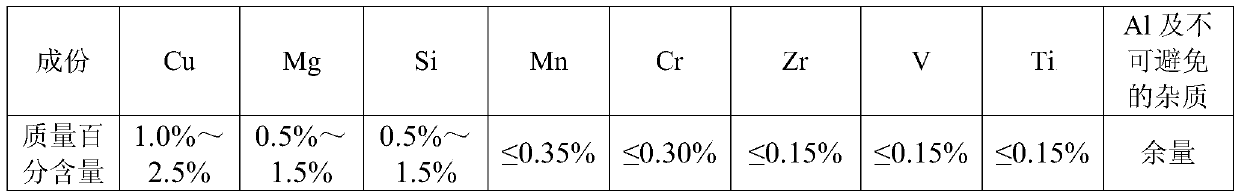

[0031] (1) Prepare aluminum alloy raw materials according to the ratio, and add the prepared aluminum alloy raw materials into a smelting furnace for uniform mixing and then melt and cast them into aluminum alloy ingots, wherein the aluminum alloy raw materials include the following components in mass percentage:

[0032]

[0033] Cu is an element combined with Mg, and Mg is an element combined with Cu and Si. The appropriate content can not only effectively improve the strength of the aluminum alloy material but also avoid cracks that may occur during bending due to the excessive strength of the aluminum alloy material.

[0034] Mn, Cr, Zr and V ensure uniform recrystallization and grain refinement during extrusion. When at least one of Mn, Cr, Zr, and V is not included in the aluminum alloy material, grains of the aluminum alloy material may be coarsened due to F...

Embodiment 2

[0055] A method for manufacturing a 2000 aluminum alloy profile, comprising the following steps in sequence:

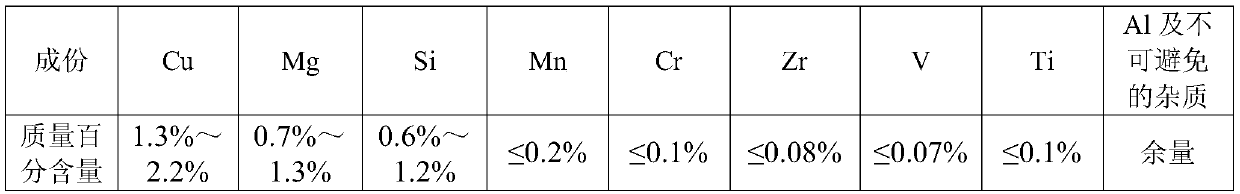

[0056] (1) Prepare aluminum alloy raw materials according to the ratio, and add the prepared aluminum alloy raw materials into a smelting furnace for uniform mixing and then melt and cast them into aluminum alloy ingots, wherein the aluminum alloy raw materials include the following components in mass percentage:

[0057]

[0058] (2) Homogenization: heat the aluminum alloy ingot prepared in step (1) at a temperature of 540° C. for more than 3 hours, and then cool the homogenized ingot to room temperature.

[0059] (3) Extrusion: first heat the billet cooled to room temperature to 350° C. to 450° C., and then place the heated billet in an extruder for hot extrusion to obtain an aluminum alloy profile.

[0060] In the extrusion step, the extruding speed of the aluminum alloy profile from the extruder is above 15 m / min, and the extrusion ratio is above 32.

[0061] ...

Embodiment 3

[0066] A method for manufacturing a 2000 aluminum alloy profile, comprising the following steps in sequence:

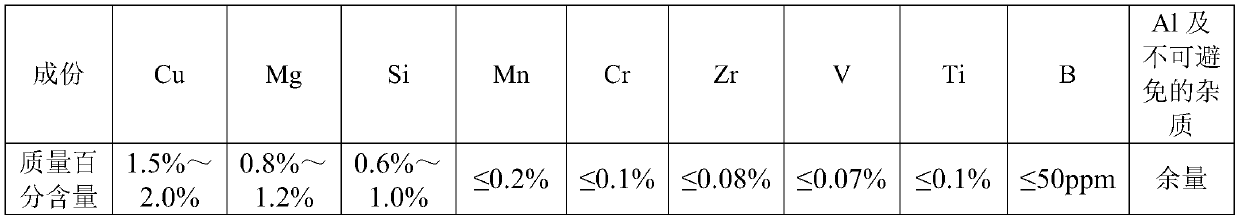

[0067] (1) Prepare aluminum alloy raw materials according to the ratio, and add the prepared aluminum alloy raw materials into a smelting furnace for uniform mixing and then melt and cast them into aluminum alloy ingots, wherein the aluminum alloy raw materials include the following components in mass percentage:

[0068]

[0069] B, like Ti, can refine the casting structure and suppress the occurrence of cracks during casting when producing aluminum alloy materials, and an appropriate content can prevent the increase in the number of coarse intermetallic compounds and also prevent possible deterioration of bendability. Among them, the content of B is more preferably 20 ppm or less.

[0070] It should be noted that, in this aluminum alloy raw material, inevitable impurities such as Fe and Zn are contained. When Fe content is high, Fe will reduce the grain size of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com