Unidirectional moisture-transfer printing process for moisture-absorbing cool fabric

A printing process and one-way moisture-wicking technology, which is applied in the field of fabric printing processing, can solve the problems of sweat sticking to the skin and clothes, poor moisture absorption and air permeability, and stuffy feeling when wearing, so as to promote firmness, enhance hydrophilicity, and improve The effect of one-way moisture transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

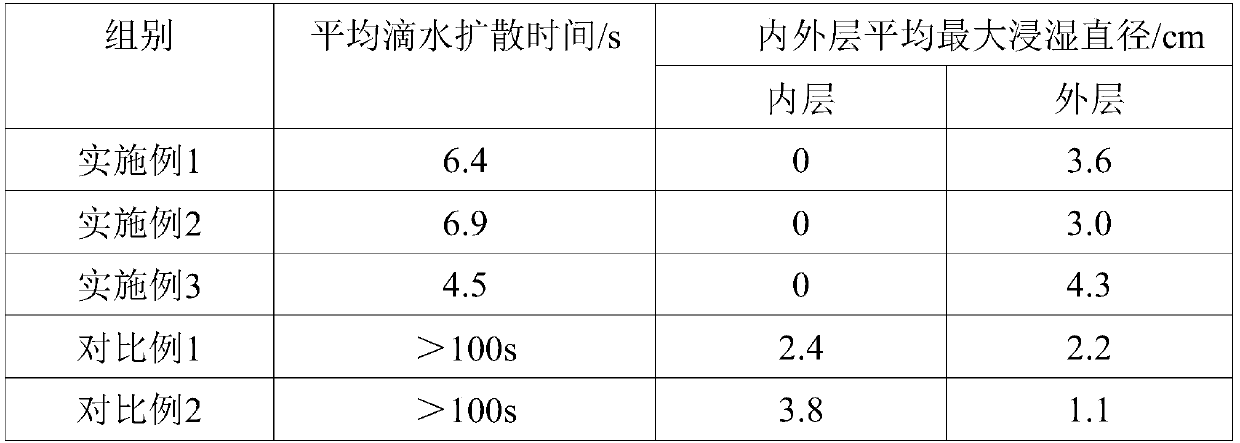

Examples

Embodiment 1

[0024] (1) Spraying: Spray mist activator on 5kg polyester fabric, the amount of activator is to spray 350mL activator evenly per kg polyester fabric, and dry at 80°C for 2h;

[0025] (2) Printing: the ink is passed through the printing roller to form a pattern on the PET film, and then the pattern on the PET film is transferred to the polyester fabric;

[0026] (3) Steaming: put the printed polyester fabric into a steamer for steaming, the steaming temperature is 110°C, the steaming time is 12 minutes, and then the PET film is peeled off;

[0027] (4) Cooling: Put the polyester fabric after peeling off the PET film into the autoclave, fill the autoclave with nitrogen to make the pressure in the autoclave reach 3.5 MPa, and pour 5°C ice water into the jacket of the autoclave, cool for 20 minutes, and after cooling Transfer to room temperature environment.

[0028] The activator consists of 15g diacetone acrylamide, 0.75g ammonium persulfate, 90g water.

[0029] The ink consi...

Embodiment 2

[0031] The spray amount of the activator in Example 1 is replaced by 300mL, and all the other operations are the same as in Example 1.

Embodiment 3

[0033] The ink in Example 1 is replaced by the ethanol solution (ethylene glycol diglycidyl ether , the volume ratio of ethanol is 1:1), and all the other operations are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com