Reinforced flow guide type large-flow injection device of gaseous fuel engine

A gas fuel and injection device technology, which is applied in combustion engines, internal combustion piston engines, engine components, etc., can solve the problems affecting the quality of natural gas combustion, the inability of injection holes to play a good role in guiding gas flow, and hindering the efficiency of natural gas intake. problems, to achieve the effect of improving mixing, improving combustion quality, and reducing NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

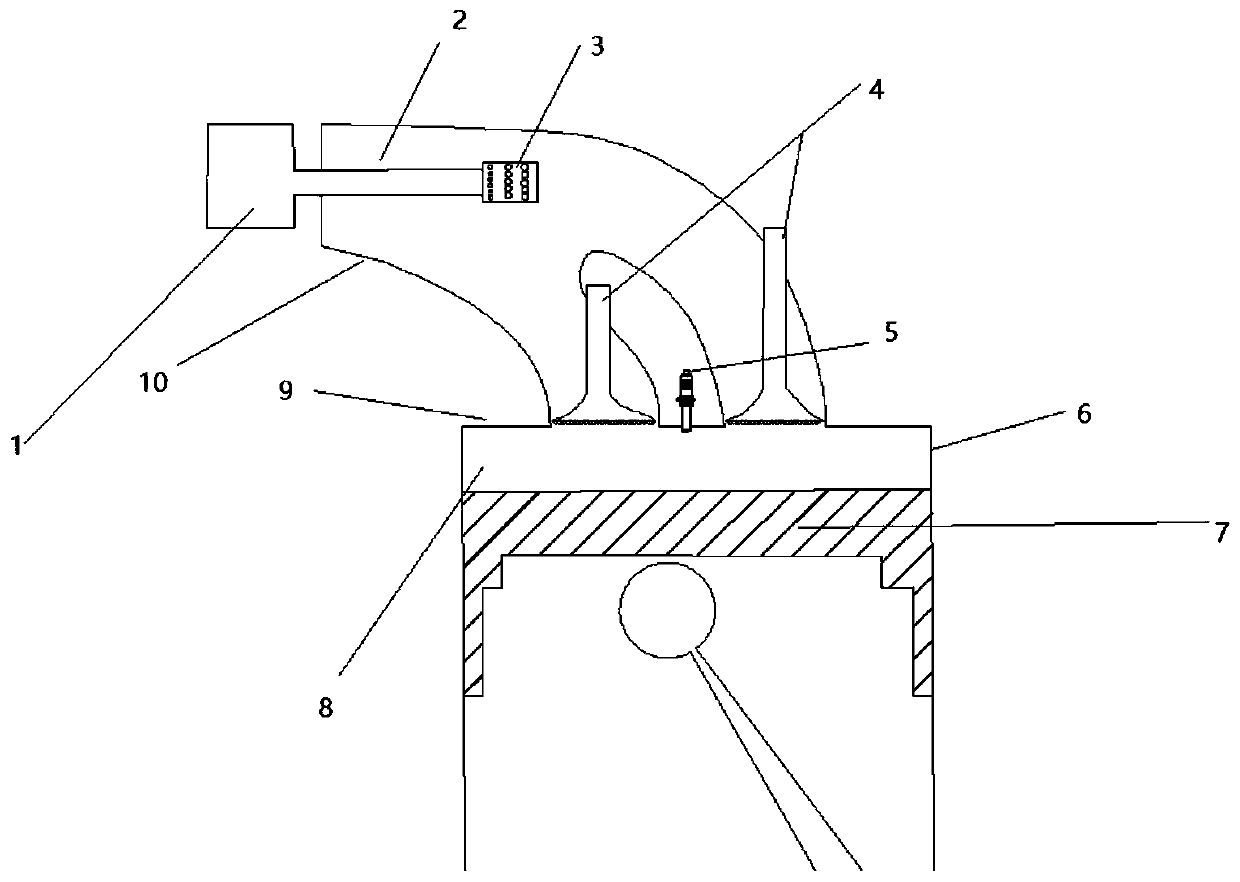

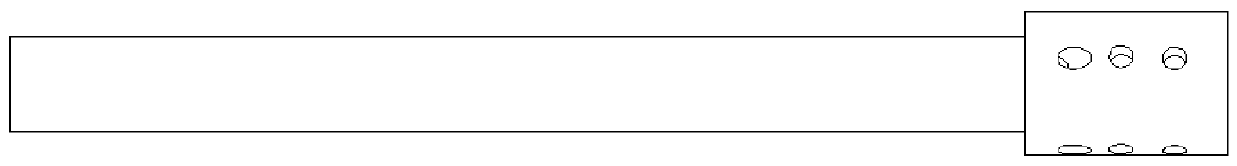

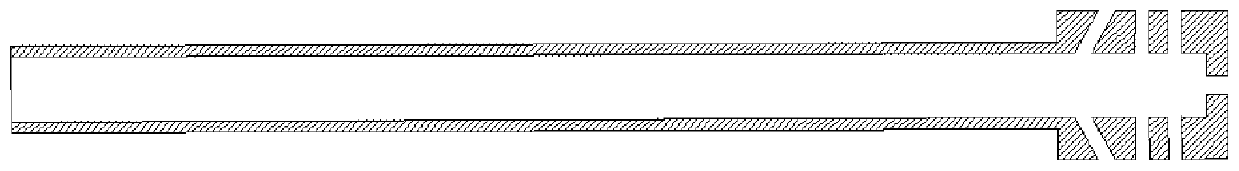

[0019] combine Figure 1-5 , the present invention includes intake manifold 10, cylinder head 9, gas injection valve 1, gas guide pipe 2, gas nozzle 3, gas nozzle 3 is connected with gas injection valve 1 through gas guide pipe 2, gas nozzle 3 Go deep into the intake manifold, thicken the pipe wall near the end of the gas nozzle, and process multiple groups of nozzle holes at the thickened part. The center of each group of nozzle holes is evenly distributed along the circumference of the pipe wall, and each group of nozzle holes The center is composed of a plurality of nozzle holes, thickening treatment is carried out at the nozzle to reduce the diameter-depth ratio of the nozzle holes, so that each nozzle hole has a better flow guiding effect, and the gas nozzle 3 has a porous structure. The axial direction of the injection hole and the jet flow can pass through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com