Method for designing triangular rubber core structure of tire

A technology of apex rubber core and structure design, applied in the field of tire structure, can solve the problems of time-consuming and laborious, unable to obtain the tire apex rubber core structure, unsatisfactory mechanical-related performance results, etc., achieves reliable principle, improves structural design efficiency, and is easy to implement The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to understand the above-mentioned purposes and advantages of the present invention more clearly, the specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings:

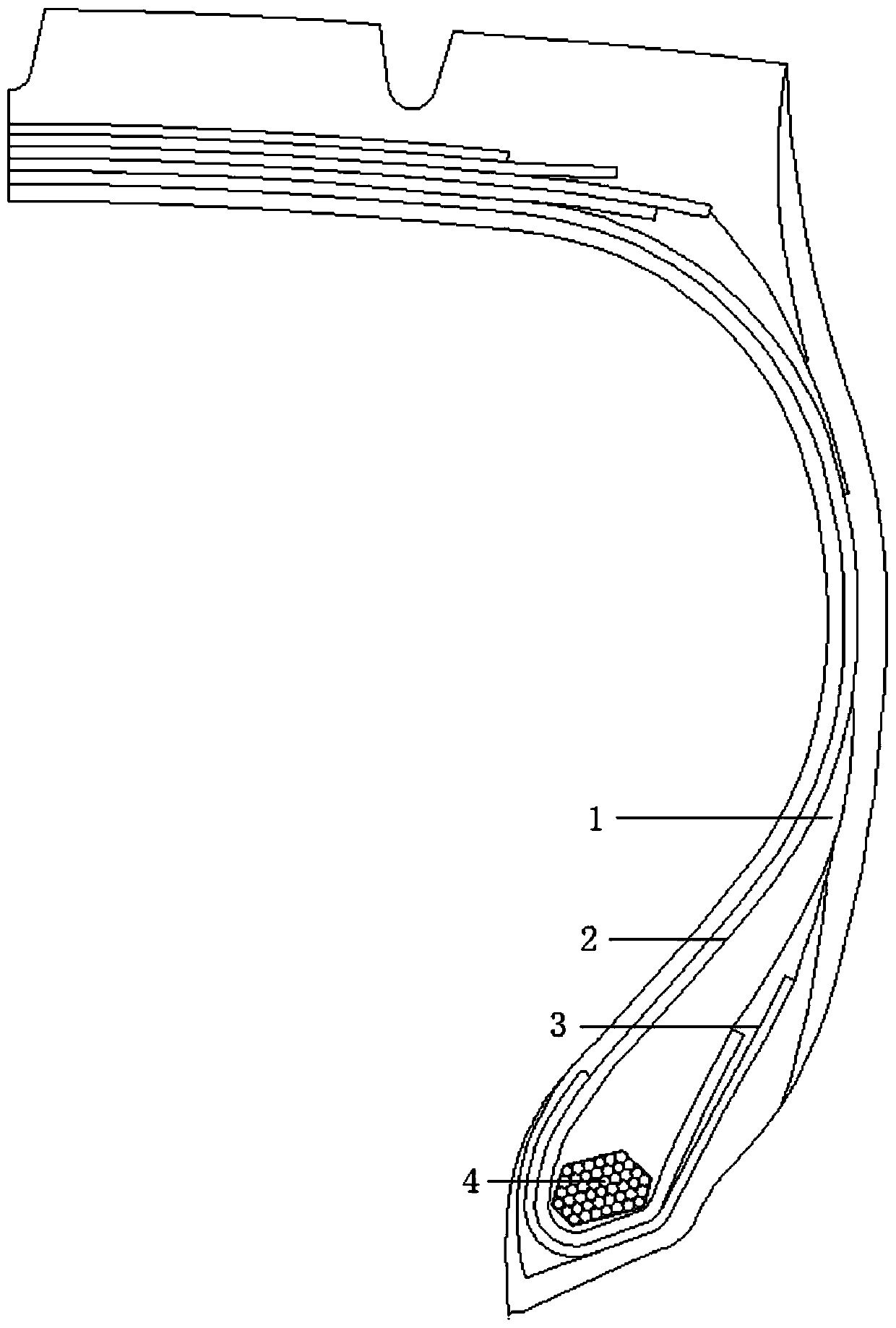

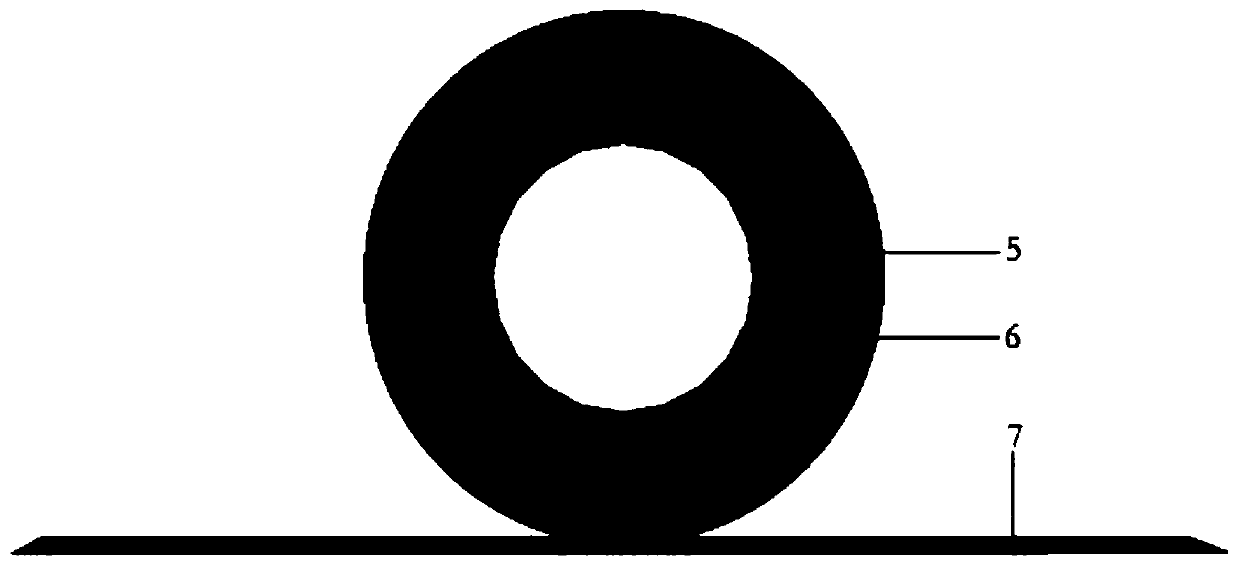

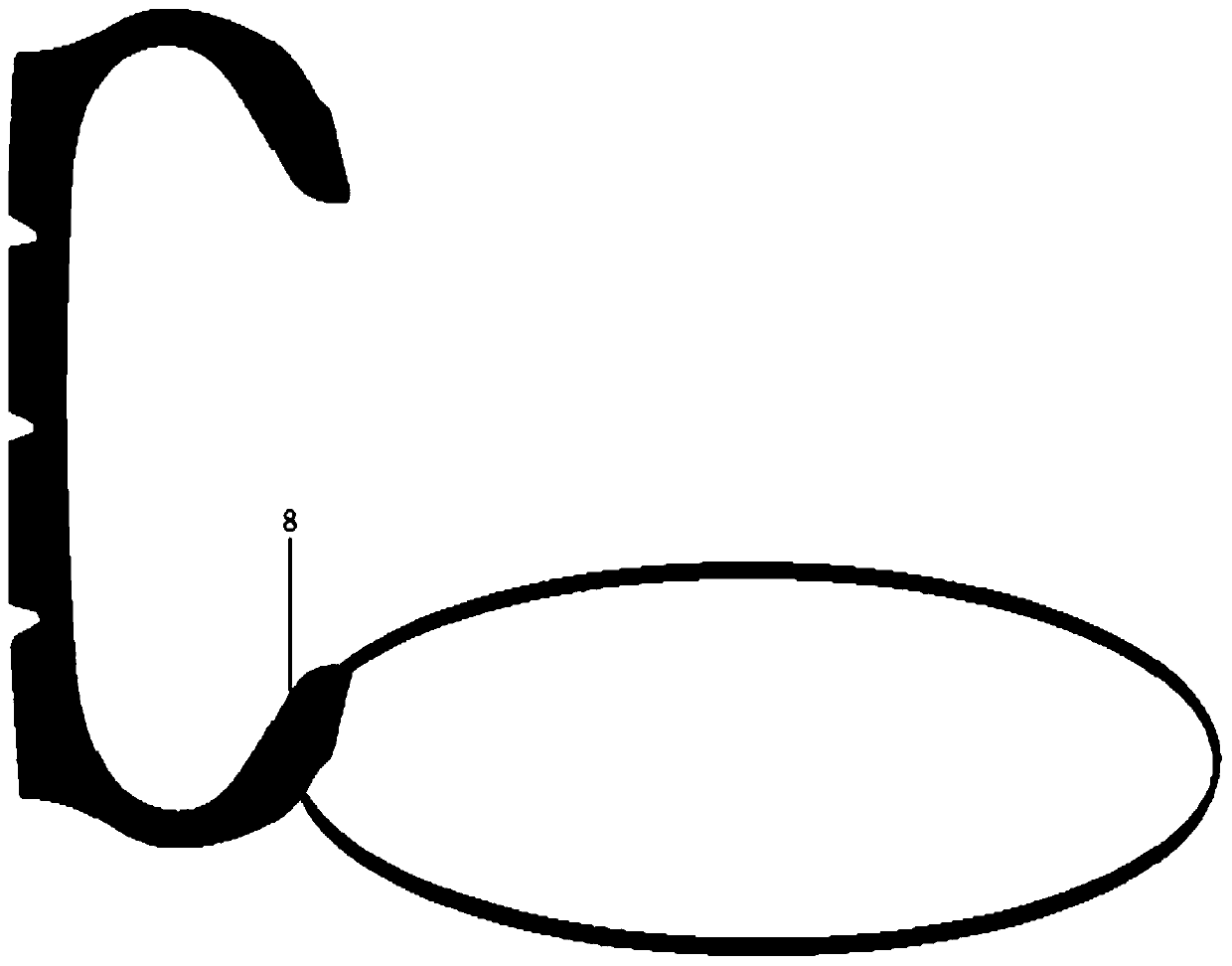

[0048] The present invention relates to a structure design method of a tire apex, specifically a method for determining the material boundary position of a multi-formulation apex structure, such as upper and lower / soft and hard apex structures, upper, middle and lower three-layer apex structures The rubber core structure or multi-layer apex core structure, creatively proposed the secondary development function based on finite element software for the first time, and wrote the tire section node information and the minimum value of the maximum principal strain into the finite element software result file. After the value is calculated, the cloud diagram of the minimum value of the maximum principal strain of the apex rubber core is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com