Heterojunction silicon wafer transmission positioning device and method

A positioning device and heterojunction technology, applied in transportation and packaging, conveyor objects, photovoltaic power generation, etc., can solve the problem that the transmission positioning mechanism is difficult to meet the needs of silicon wafer transportation, the speed of the walking arm cannot be too fast, and the silicon wafer transmission Insufficient precision and other problems, to achieve the effect of reducing human intervention, easy daily maintenance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

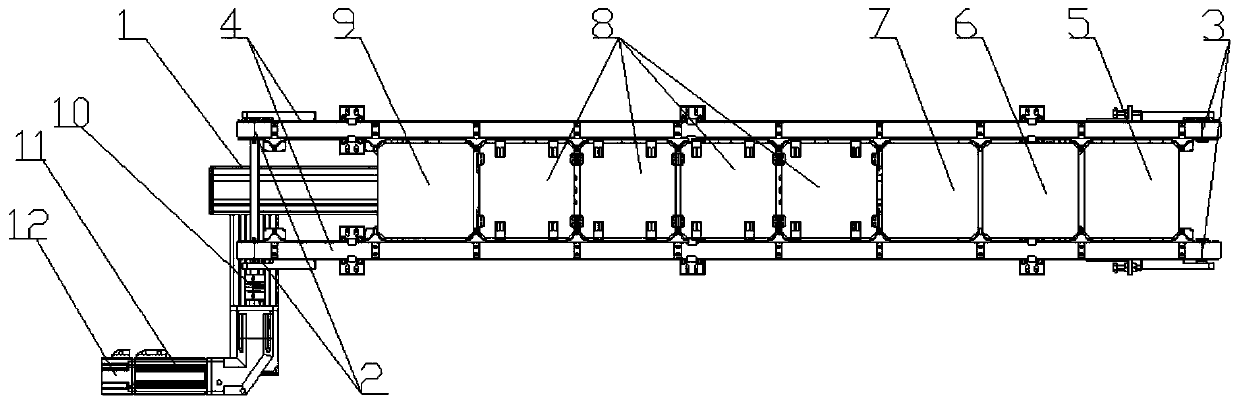

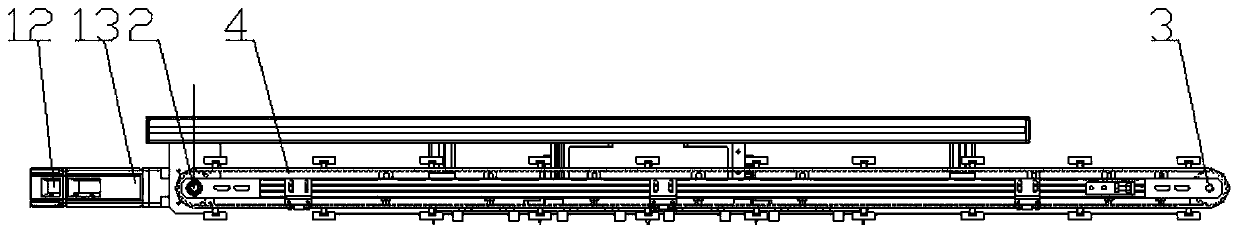

[0037] Implementation case 1: With the development of the country, environmental protection issues have arisen spontaneously, and the government has paid more and more attention to the field of new energy. The continuous advancement of Industry 4.0, and the development and improvement of mechanical intelligence will lead industrial production to In the new era of revolution, through intelligent manufacturing and intelligent control systems, industrial production can be truly achieved, labor intensity can be reduced, labor efficiency can be improved, and the level of industrial production has reached a new level. In the production process of the PECVD process of amorphous silicon, solar SHJ photovoltaic cells are basically operated in the form of automatic assembly lines, so the cells need to be transported between the automation and the main equipment for many times. Due to the SHJ cells The surface is very sensitive, which requires high equipment and high position accuracy whe...

Embodiment example 2

[0043] Implementation Case 2: This implementation is further optimized on the basis of Embodiment 1. This embodiment focuses on the improvements compared with Embodiment 1, and the similarities will not be repeated, such as Figure 5 As shown, the frame 1 is provided with a synchronous belt limiting module, which is used to prevent the synchronous belt 4 from shaking on the Y axis and jumping on the Z axis. , the Y-axis limit bearing 17 is a soft elastic structure for the synchronous belt 4 during operation, so that under the action of the driving wheel set 2 and the driven wheel set 3, a slight swing in the up and down direction will occur. Therefore, we set The synchronous belt 4 limit module is used to limit the vertical direction of the synchronous belt 4 to ensure the stable and reliable operation of the synchronous belt 4.

Embodiment example 3

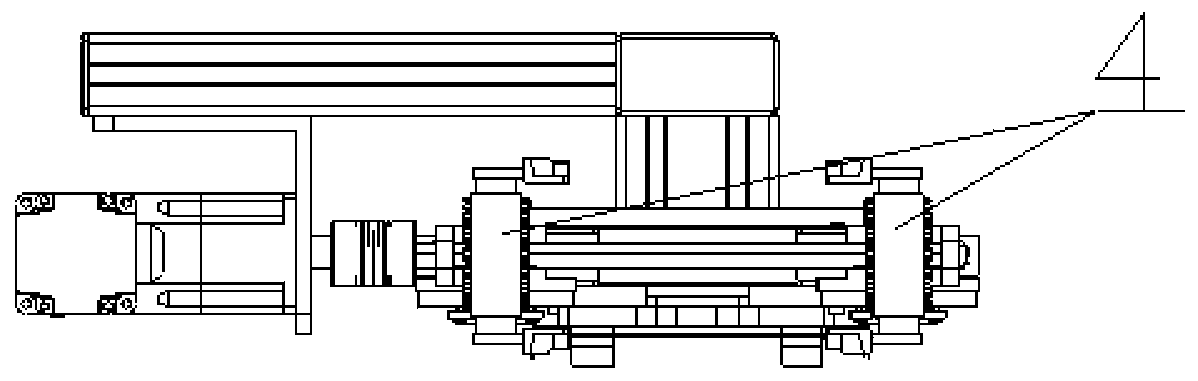

[0044] Implementation Case 3: This implementation is further optimized on the basis of Embodiment 1. This embodiment focuses on the improvements compared with Embodiment 1, and the similarities will not be repeated. The drive components include a drive motor 12 and a reducer 11 , the drive motor 12 is connected to the reducer 11 in transmission, and a coupling 10 is arranged between the reducer and the driving shaft. The assembly is made into a modular structure, including a drive motor 12, a reducer 11 and a shaft coupling 10, which are arranged in a modular structure, so that it is easy to disassemble, easy to maintain, and low in cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com