Surface-mounted permanent magnet rotor disc of high-strength axial magnetic field motor

An axial magnetic field, permanent magnet rotor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, electromechanical devices, etc. To solve the problems of air gap and other problems, to solve the problem of structural safety, easy and convenient transfer, and reduce the temperature rise of the rotor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] For axial field permanent magnet motors, the structural strength of the rotor directly affects the maximum speed and power density of this type. With the continuous development of axial field motor technology, the protection of permanent magnets and the improvement of rotor strength have become the field of this field. An important research hotspot and direction.

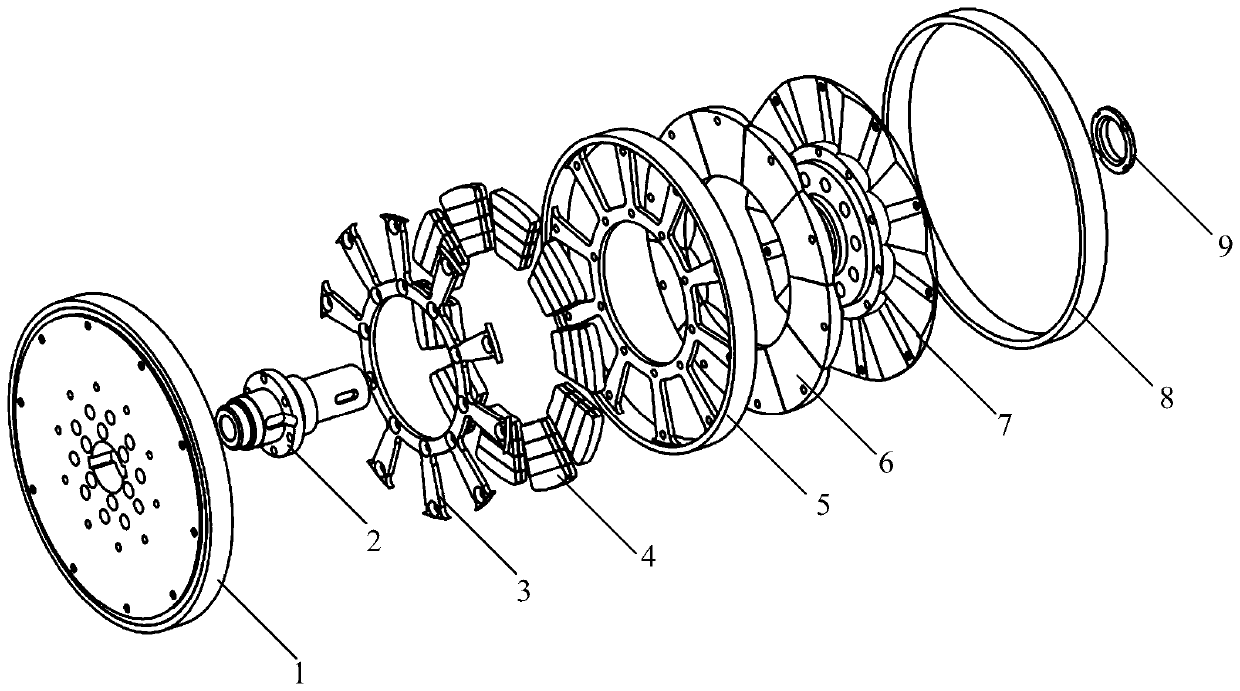

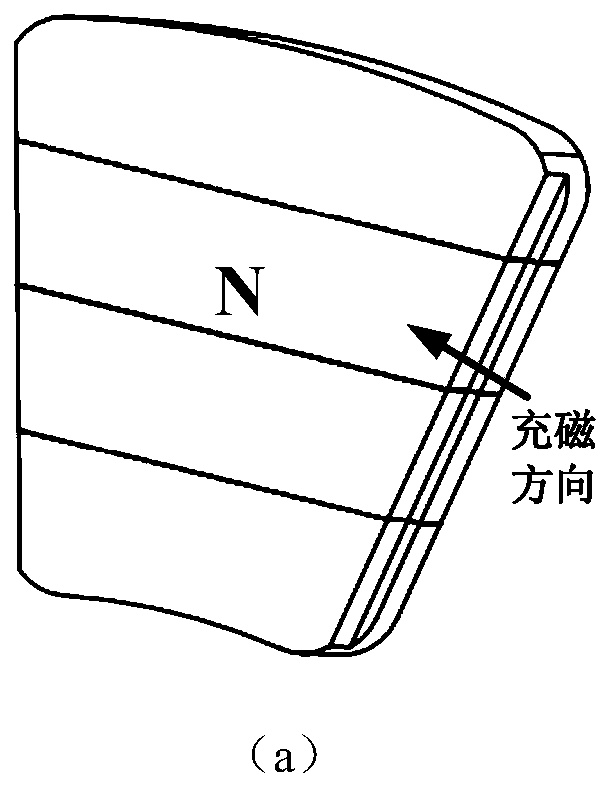

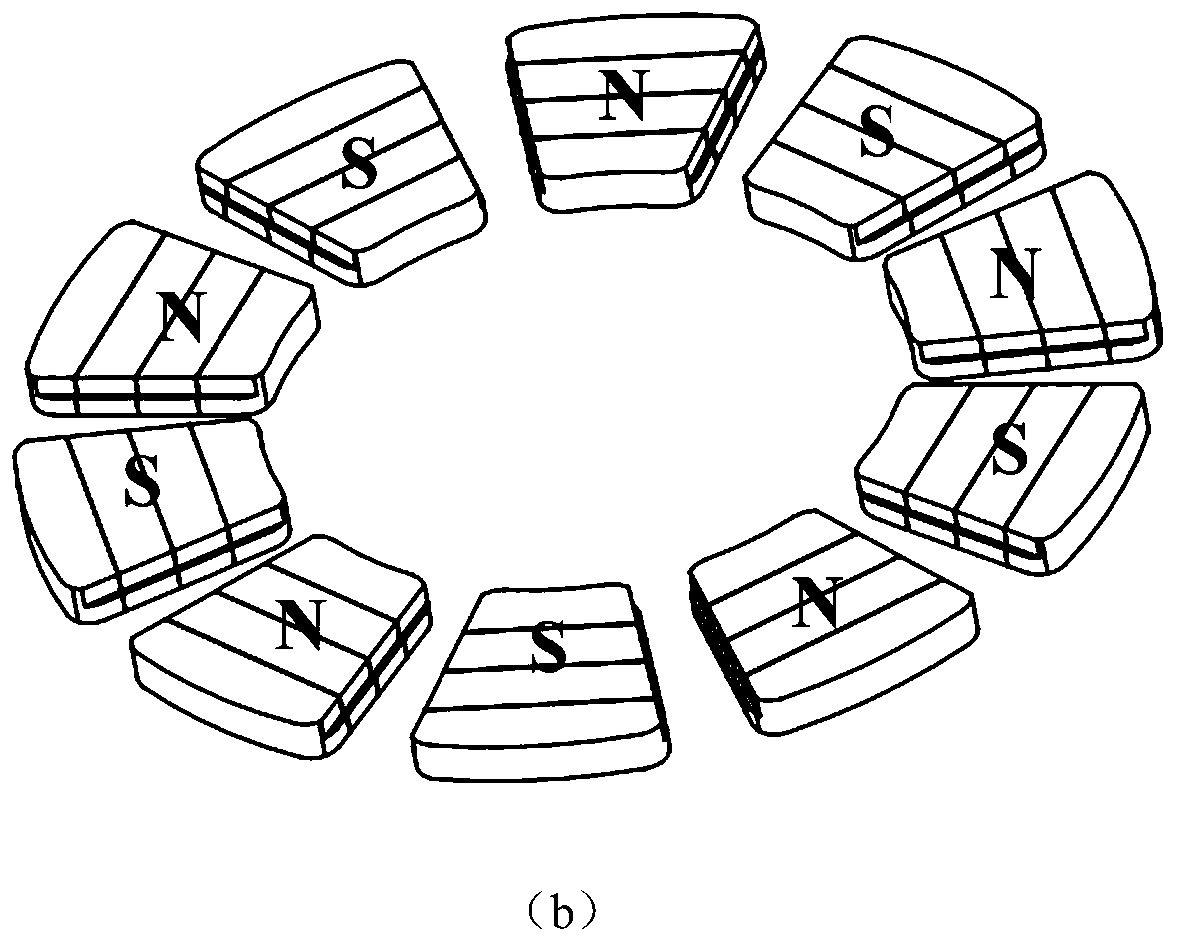

[0032] The present invention proposes a surface-mounted permanent magnet rotor disk for a high-strength axial magnetic field motor, which includes two rotor disks 1 mounted symmetrically on the rotating shaft 2 facing each other, and a space is left between the two rotor disks 1 for installing the stator disk; Each rotor disc 1 includes spoke-shaped permanent magnet pressure plate 3 of polymer material, trapezoidal permanent magnet 4, fixed frame 5 of polymer material, rotor magnetic back yoke 6, rotor support plate 7 and carbon fiber sheath 8 arranged in sequence;

[0033] The rotor magnetically conductive b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com