Greenhouse efficiency-increasing system and method integrating biogas purification application

A technology for greenhouses and greenhouses, which is applied to the greenhouse efficiency enhancement system and field of integrated biogas purification applications, and can solve problems such as greenhouse collapse, environmental pollution, and temperature fluctuations, so as to reduce supply costs, reduce emission pollution, and achieve zero emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

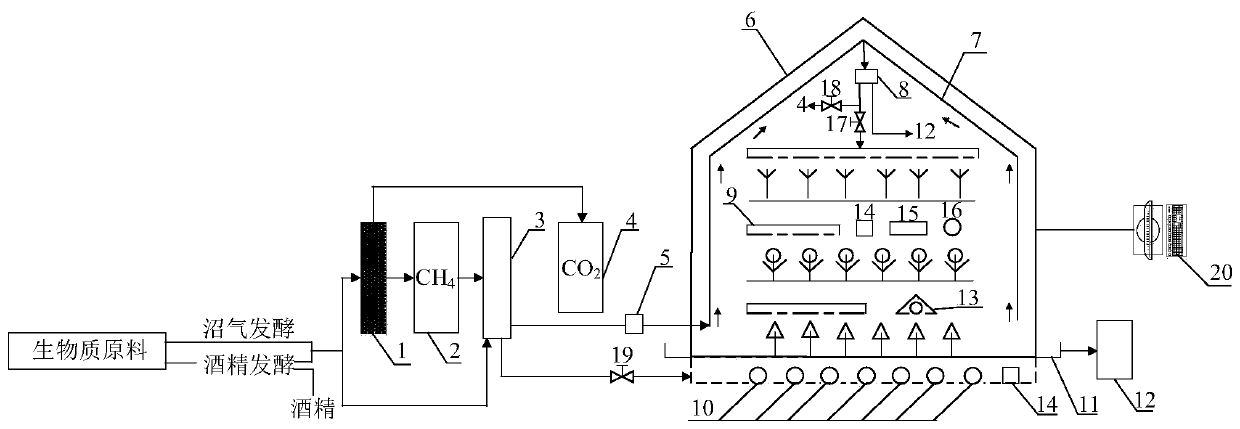

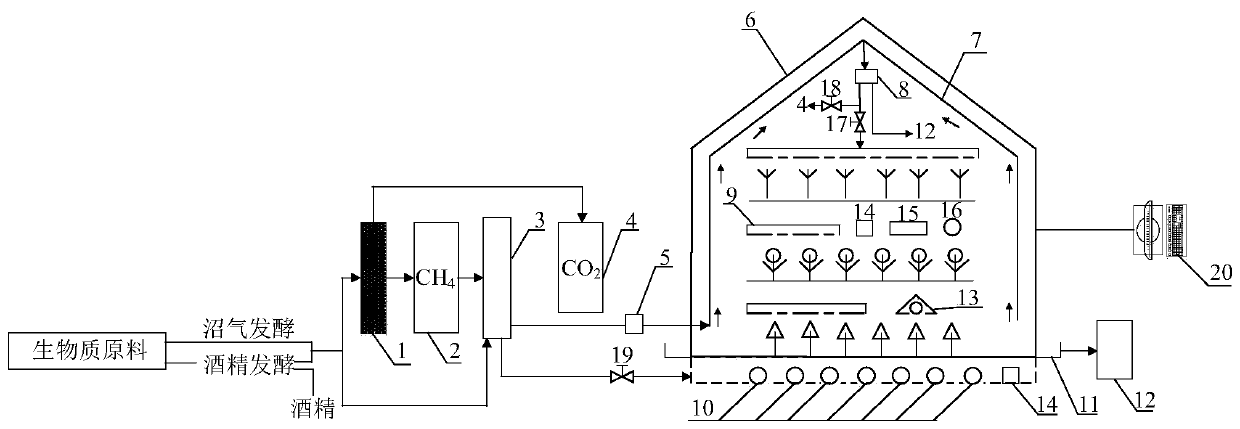

[0027] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

[0028] The present invention utilizes CH in the biogas purification process 4 and CO 2 , to meet the requirements of the greenhouse for temperature, light, water and CO 2 Fertilizer needs. According to the actual situation of the greenhouse, choose to burn biogas or CH 4 Provide heat for the greenhouse, and the CO produced by the condensation of flue gas 2 and H 2 O can be used in greenhouse CO 2 Gas fertilizer application and water for crops. At the same time, the radiators on the side walls of the greenhouse can melt the snow on the top of the greenhouse in winter. The water obtained during the melting process can also be used as water for greenhouse crops. Biogas lamps are installed in the greenhouse to meet the requirements of greenhouse lighting. Alcoholic fermentation and biogas fermentation are centrally arranged to facilitate the production of raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com