A kind of preparation technology of solid lactic acid

A lactic acid, solid technology, applied in dairy products, other dairy products, mixers with rotary stirring devices, etc., can solve the problem of reducing the service life of device components, and the safety and stability effect of a single screw hole fastening method cannot be fully guaranteed and polished. Problems such as high head consumption, to achieve the effect of eliminating non-directional relative torsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

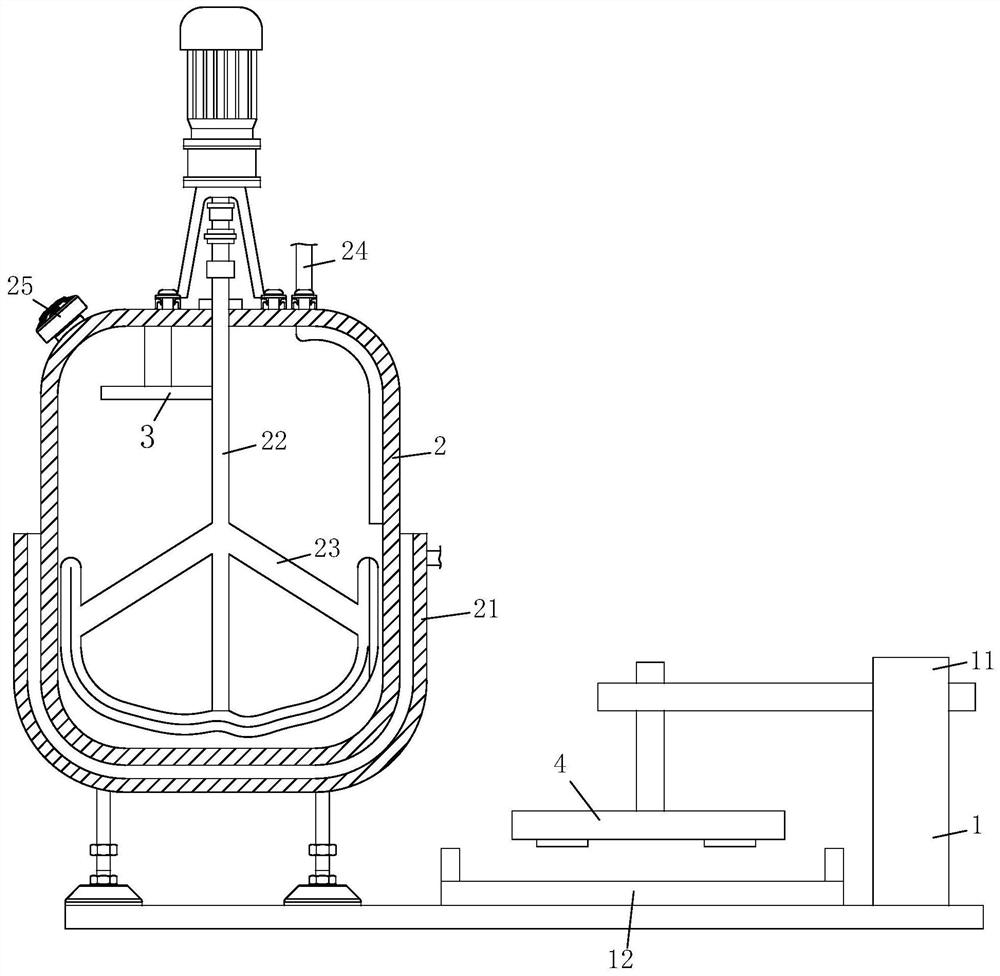

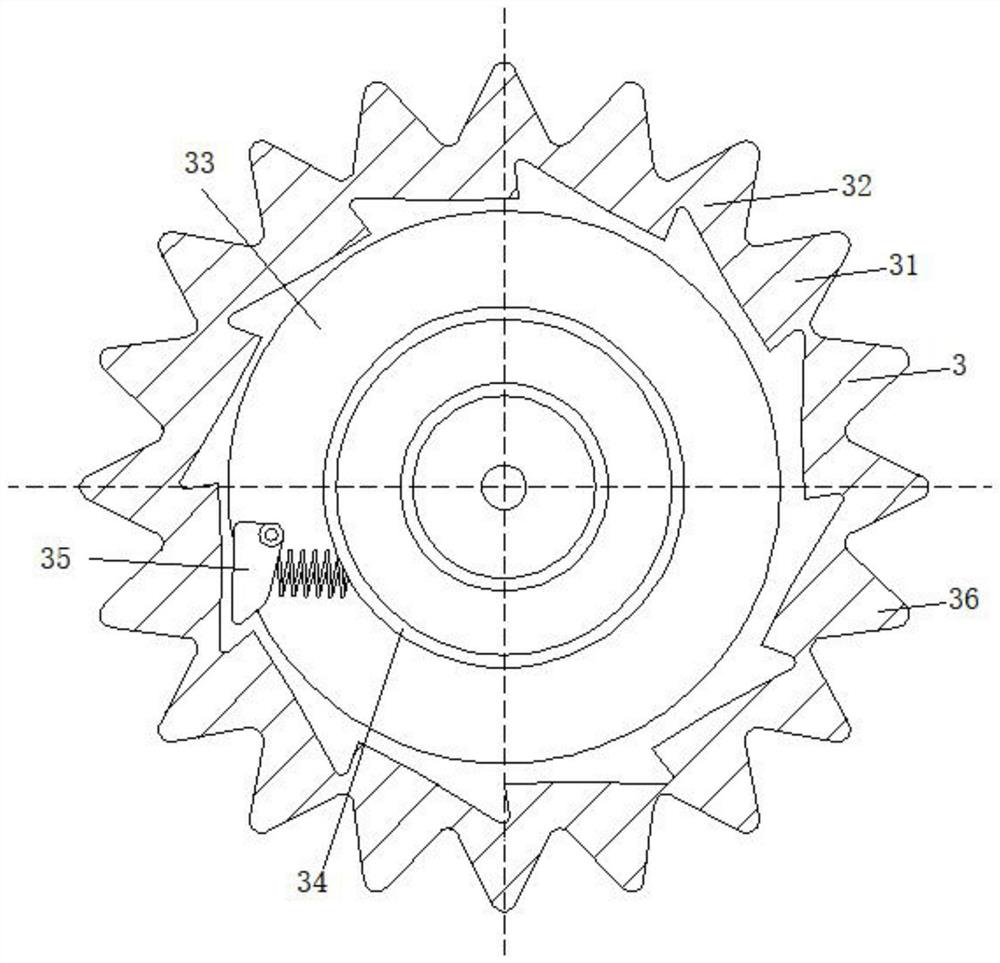

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

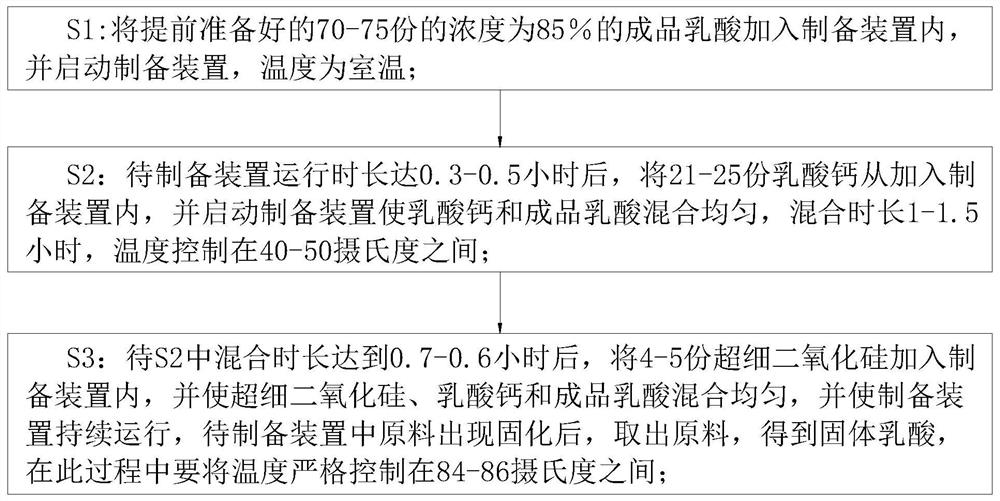

[0029] Such as Figure 1-Figure 6 Shown, the preparation technology of a kind of solid lactic acid of the present invention, this technology comprises the following steps:

[0030] S1: Add 70-75 parts of finished lactic acid with a concentration of 85% prepared in advance into the preparation device, and start the preparation device at room temperature;

[0031] S2: After the preparation device has been running for 0.3-0.5 hours, add 21-25 parts of calcium lactate into the preparation device, and start the preparation device to mix calcium lactate and finished lactic acid evenly. The mixing time is 1-1.5 hours, and the temperature is controlled at Between 40-50 degrees Celsius;

[0032] S3: After the mixing time in S2 reaches 0.7-0.6 hours, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com