Hydroisomerization catalyst having nano ZSM-22 zeolite loaded with phosphorus and nickel as well as preparation method and application of hydroisomerization catalyst

A ZSM-22, hydroisomerization technology, applied in the field of hydroisomerization performance research, can solve the problems of large Ni loading capacity and difficulty in further improving catalyst hydroisomerization activity, and achieve high isomer yield efficiency, high isomer selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of ZSM-22-De carrier is:

[0036] (1) 0.3gAl 2 (SO 4 ) 3 18H 2 Dissolve O in 30mL deionized water, add 0.9g KOH after fully dissolved, and then slowly add 2g of 1,6-hexanediamine and stir for 1 hour to obtain a clear solution, then add 10g of silica sol solution, and form a silica-alumina gel after stirring for 1 hour (1.0Al 2 o 3 / 15K 2 O / 100SiO 2 / 37HD / 3800H 2 (2), put in a kettle and crystallize at 50° C. for 6 hours, take the kettle to obtain the initial gel, add 2 g of high molecular weight polymer (about 20,000 actual molecular weight, but not limited to this) to the initial gel under stirring conditions, Continue to stir for 4 hours, put in a kettle, and conduct static crystallization at 160° C. for 48 hours. After washing, filtering, and calcining at 500° C. for 15 hours, a zeolite sample was obtained, and a nanometer ZSM-22 zeolite containing a mesoporous structure was obtained.

[0037] (2) Carry out acid treatment to the nanom...

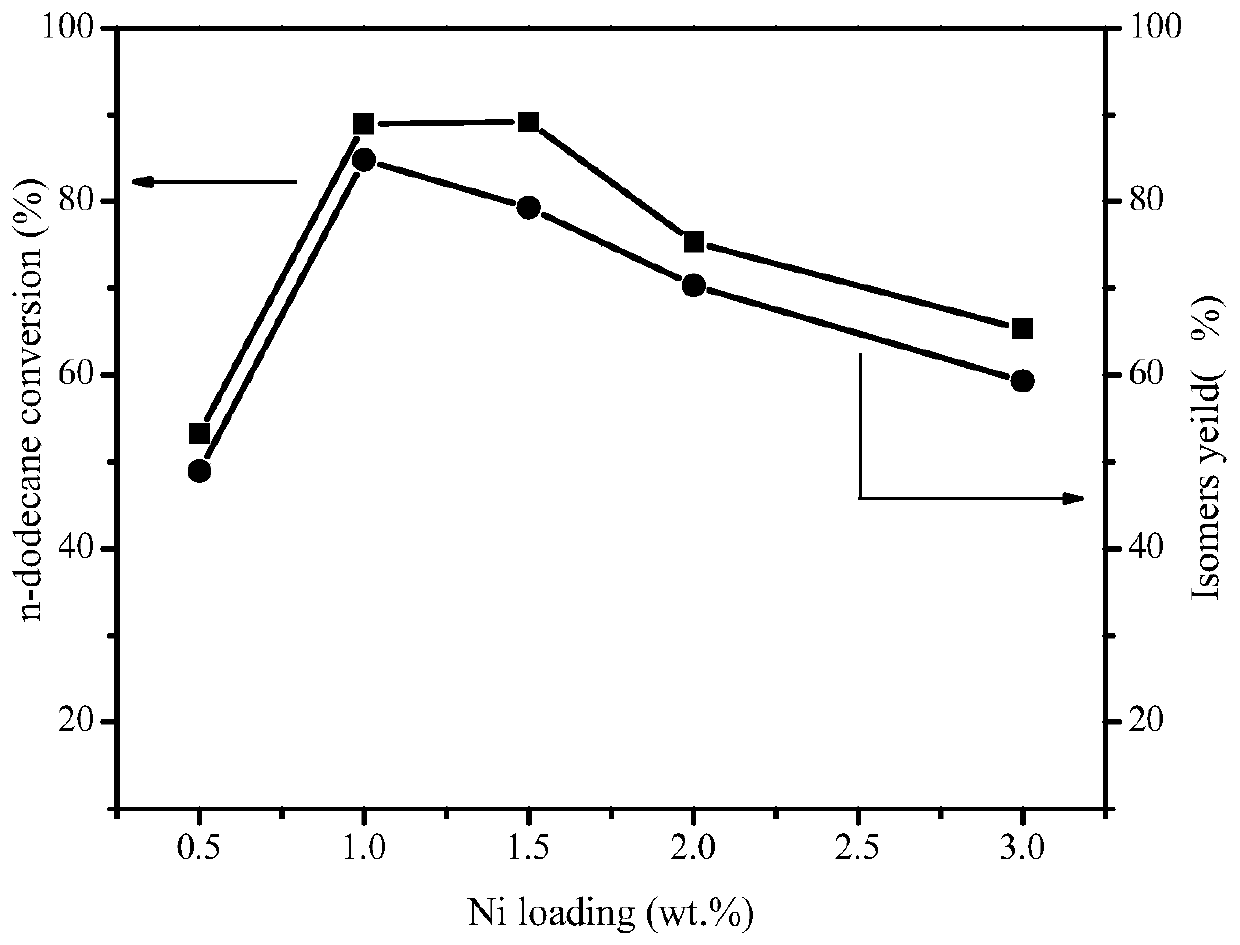

Embodiment 1

[0039] ZSM-22-De carrier 2.0g, 0.0519g Ni(NO 3 ) 2 ·6H 2 O and 0.0146 g of NH 4 h 2 PO 2 Dissolve it in 3.0mL of distilled water, add it dropwise to 2g of ZSM-22-De powder after the impregnation is completed, let it stand at room temperature for more than 12 hours, and dry it in an oven at 100°C for 12 hours. The catalyst precursor is compressed under a certain pressure, taking 40-60 mesh, and finally in H 2 In the atmosphere of 450 ° C for 3 hours, marked as NiP / ZSM-22-De#1 catalyst. Wherein, the loading amount of Ni is 0.5% by mass percentage, and the molar ratio of P / Ni atoms in the raw material is 1. (In the NiP / ZSM-22-De#1 catalyst, NiP only expresses that the active substance is phosphorus-nickel substance, which does not mean that the molar ratio of Ni and P in the final product is 1:1, 13 form volatile)

Embodiment 2

[0041] ZSM-22-De carrier 2.0g, 0.1038g Ni(NO 3 ) 2 ·6H 2 O and 0.0292 g of NH 4 h 2 PO 2 Dissolve it in 3.0mL of distilled water, add it dropwise to 2g of ZSM-22-De powder after the impregnation is completed, let it stand at room temperature for 12 hours, and dry it in an oven at 100°C for 12 hours to prepare the catalyst The precursor is compressed under a certain pressure, taking 40-60 mesh, and finally in H 2 In the atmosphere of 450 ° C for 3 hours, marked as NiP / ZSM-22-De#2 catalyst. Wherein, the loading amount of Ni is 1.0% by mass percentage, and the molar ratio of P / Ni atoms in the raw material is 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com