Western solar power generation and cleaning integrated equipment

A solar panel and integrated technology, which is applied in photovoltaic power generation, electrical components, cleaning and flexible items, etc., can solve the problem that solar panel cleaning operations cannot use water resources efficiently, and achieve normal and stable work, efficient and fast cleaning , to ensure the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

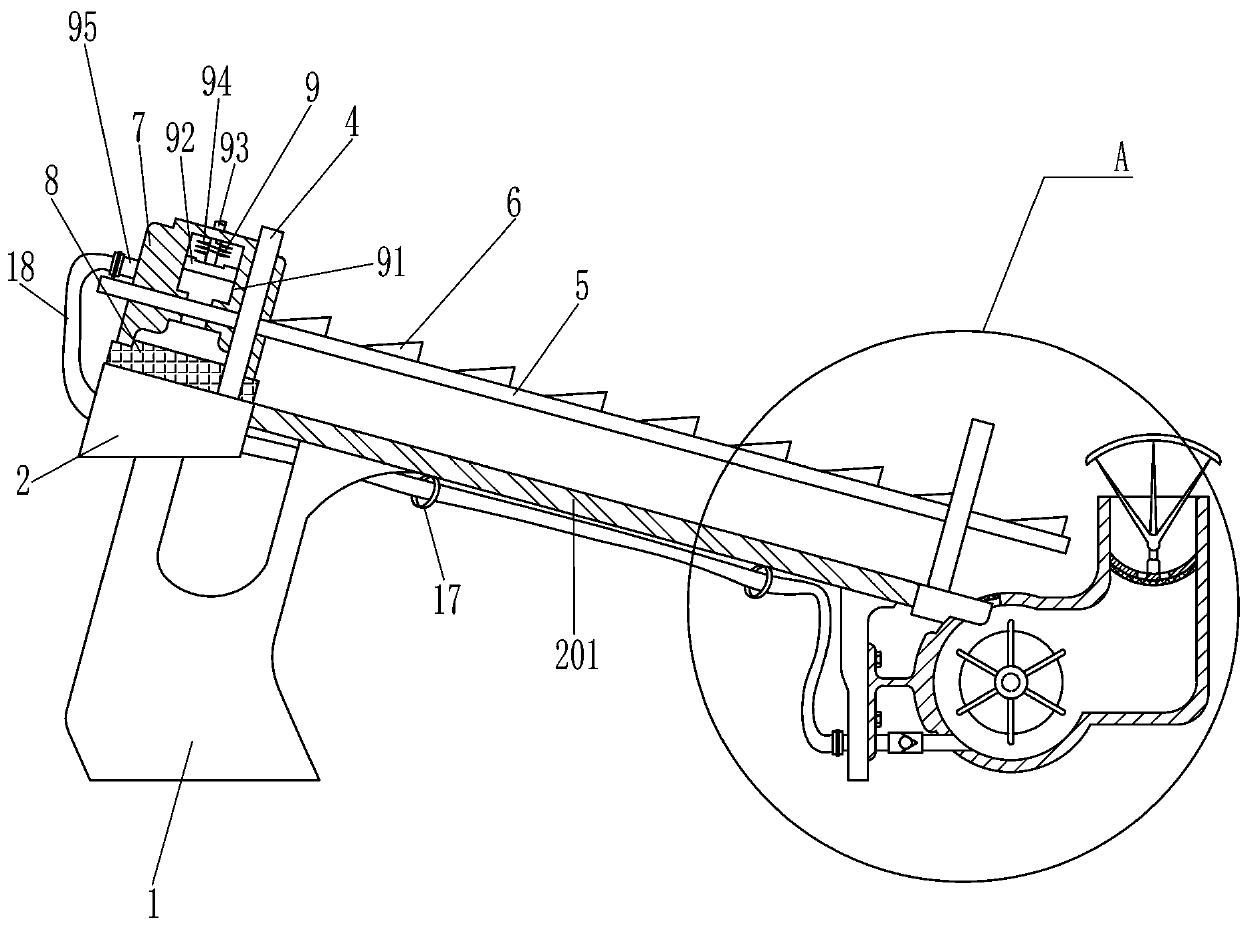

[0019] A western solar power generation and cleaning integrated equipment, such as Figure 1-3 As shown, it includes a base 1, a support block 2, a solar panel 201, a support plate 3, a mounting rod 4, a diagonal rod 5, a first wedge block 6, a mounting frame 7, a sponge block 8, a liquid pumping device 9, a second Wedge block 10, liquid reservoir 11, liquid guide 12, arc-shaped mesh plate 13, arc-shaped opening plate 14, water collector 15, drain pipe 16, guide ring 17 and telescopic hose 18, the top of base 1 is provided with The support block 2, the top of the base 1 is fixedly connected with a solar panel 201, the bottom of the solar panel 201 is provided with a support plate 3 on the side away from the base 1, the front and rear sides of the support block 2 are provided with mounting rods 4, and the side of the support plate 3 is provided with There is a liquid reservoir 11, the top of the liquid reservoir 11 is provided with a liquid guide 12, the top of the liquid guide...

Embodiment 2

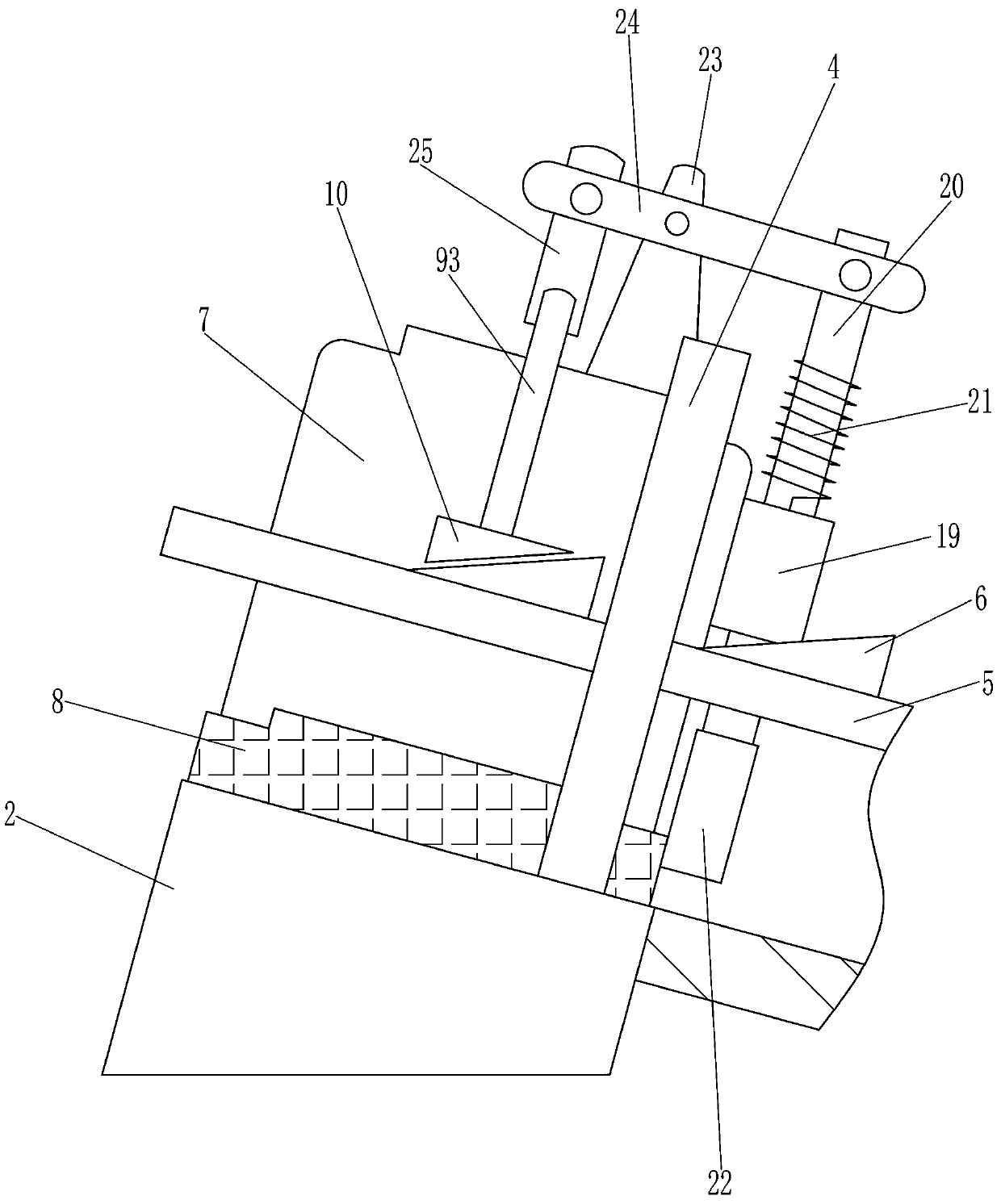

[0023] On the basis of Example 1, such as Figure 1-2As shown, also include guide sleeve 19, guide rod 20, second compression spring 21, rubber wipe block 22, mounting base 23, rotating bar 24 and vertical bar 25, mounting bracket 7 one side is provided with guide sleeve 19, guide sleeve 19 is slidingly connected with a guide rod 20, a second compression spring 21 is connected between the guide rod 20 and the guide sleeve 19, the end of the guide rod 20 is provided with a rubber wiper block 22, and the top of the mounting frame 7 is provided with a mounting seat 23, the mounting seat 23 is connected with rotating rod 24 in rotation, and U-shaped connecting rod 93 is provided with vertical rod 25, and vertical rod 25 is connected with rotating rod 24 in rotation, and the rotating rod 24 on one side away from vertical rod 25 is connected in rotation with guide rod 20 .

[0024] When the staff pulls the U-shaped connecting rod 93 to move upward, the U-shaped connecting rod 93 dr...

Embodiment 3

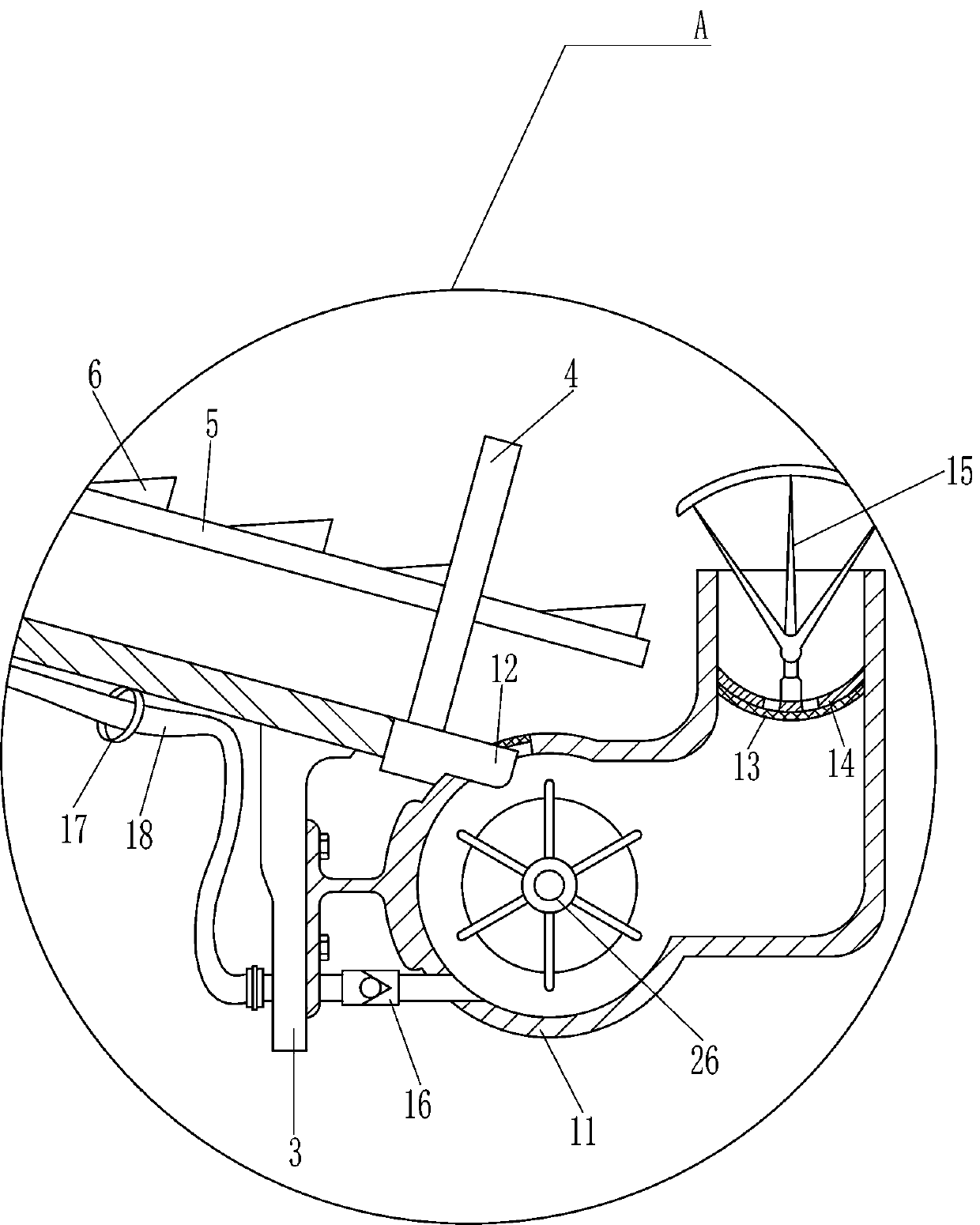

[0026] On the basis of Example 2, such as image 3 As shown, a stirring plate 26 is also included, and the liquid reservoir 11 is rotatably connected with the stirring plate 26 .

[0027] Since the surface of the solar panel 201 is made of glass, and the glass cleaning agent has low surface tension, good wettability, and has a high degree of wetting, dissolution, and dissociation and dispersion of dirt, it can be properly supplied to the liquid reservoir. Inject a certain amount of glass cleaning agent in 11, by agitating disc 26, be convenient to the sufficient mixing of glass cleaning agent and clear water, have reached the effect that guarantees that solar cell panel 201 cleans up comprehensively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com