Mechanical welding method for closely-spaced pipe joint of header

A technology of mechanical welding and close-packed tubes, which is applied to welding equipment, arc welding equipment, and the edge of workpieces, etc., can solve problems such as high work intensity, low production efficiency, and unstable welding quality, and achieve reduced labor intensity and high production efficiency. The effect of improving and stabilizing welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

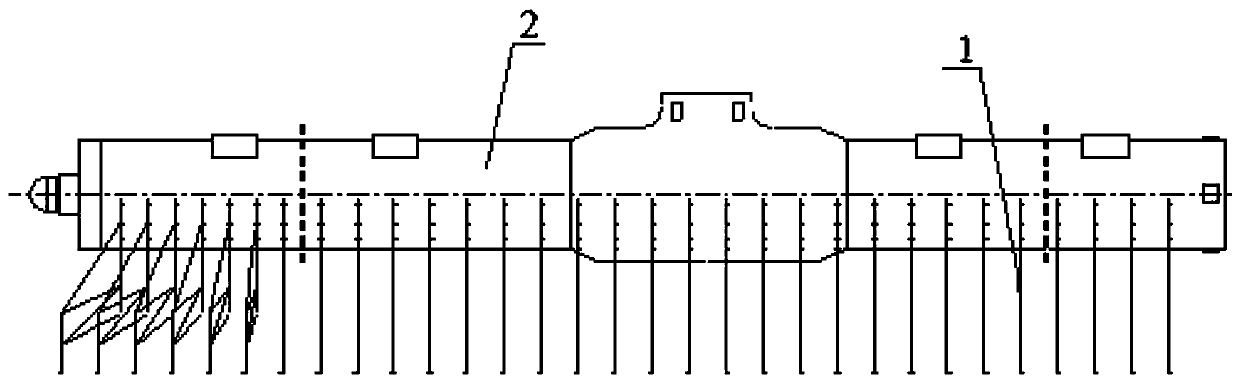

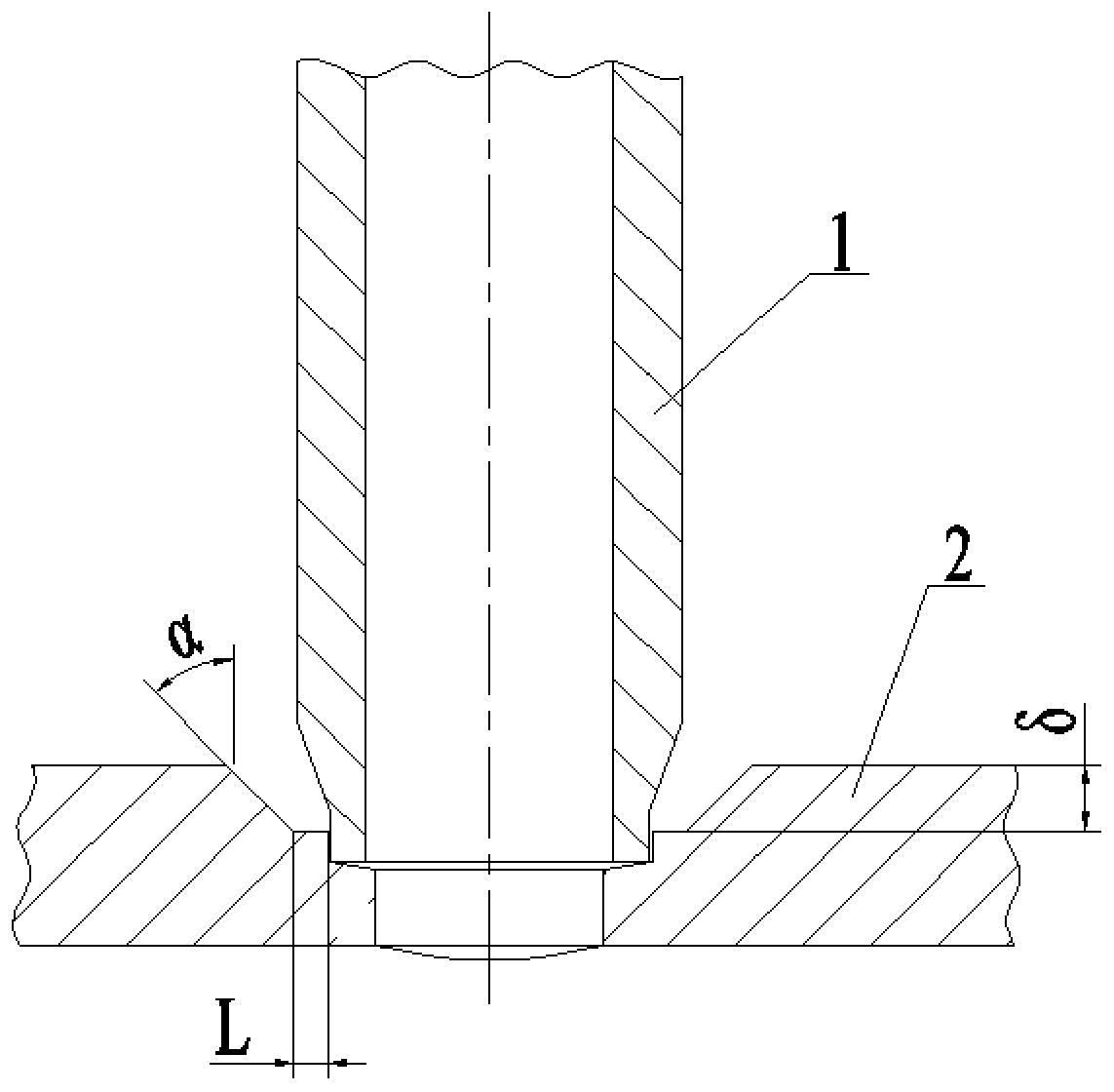

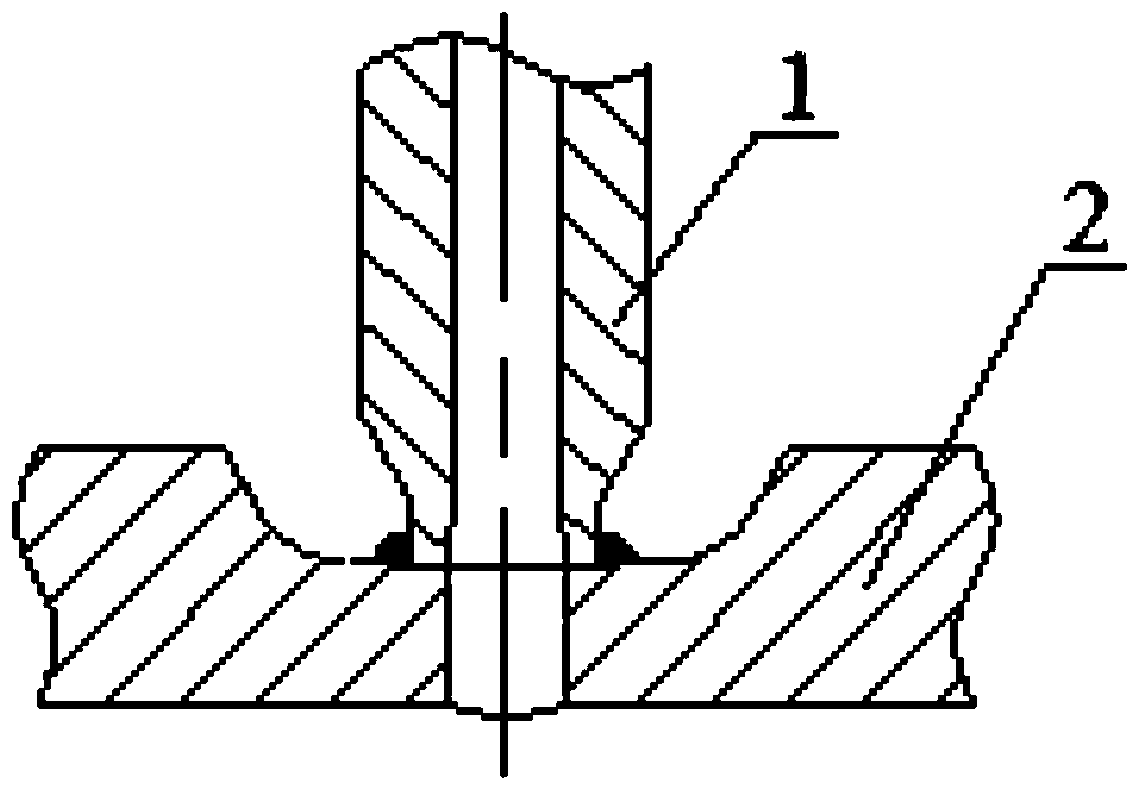

[0017] Specific implementation mode one: combine Figure 1 to Figure 3 To illustrate this embodiment, a mechanical welding method for header close-packed pipe joints described in this embodiment includes the following steps:

[0018] Step 1: Assembling and positioning: first, install the closely-packed pipe joints 1 to be welded on the pipe holes of the header 2 body, and then use electrode arc welding or solid wire gas shielded welding to weld the closely-packed pipe joints to be welded 1 for positioning welding;

[0019] Step 2: Selection of equipment process: CNC automatic welding equipment is selected as the welding equipment, and the welding process adopts solid wire melting electrode gas shielded welding. The welding shielding gas is a mixture of argon and carbon dioxide, and the gas ratio of argon and carbon dioxide is determined by the user. The welding material is determined;

[0020] Step 3: Equipment clamping: according to the outer diameter and height of the pipe...

specific Embodiment approach 2

[0034] Specific implementation mode two: combination Figure 1 to Figure 3 To illustrate this embodiment, in step one of this embodiment, the welding method during tack welding is spot welding, the number of welding points is 2-3 points, and the welding points are arranged symmetrically about the center. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0035] Specific implementation mode three: combination Figure 1 to Figure 3 To illustrate this embodiment, in step 2 of this embodiment, in the mixed gas of argon and carbon dioxide, the proportion of argon is 80%-95%, and the proportion of carbon dioxide is 5%-20%. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com