A male shaft processing method and mold for an intermediate shaft of an automobile steering system

A technology of an automobile steering system and a processing method, which is applied to the male shaft processing method of the intermediate shaft of the automobile steering system and the field of molds. Processing efficiency, avoiding welding defects, and ensuring the effect of precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the drawings and embodiments, but it is not used as a basis for any limitation on the invention.

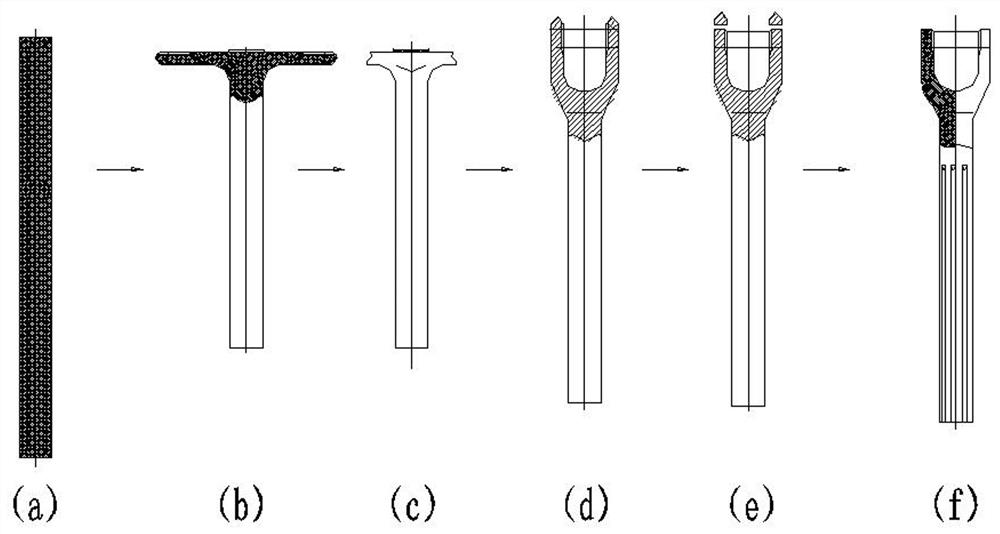

[0028] Refer to attached figure 1 As shown, a male shaft processing method of an intermediate shaft of an automobile steering system includes the following steps:

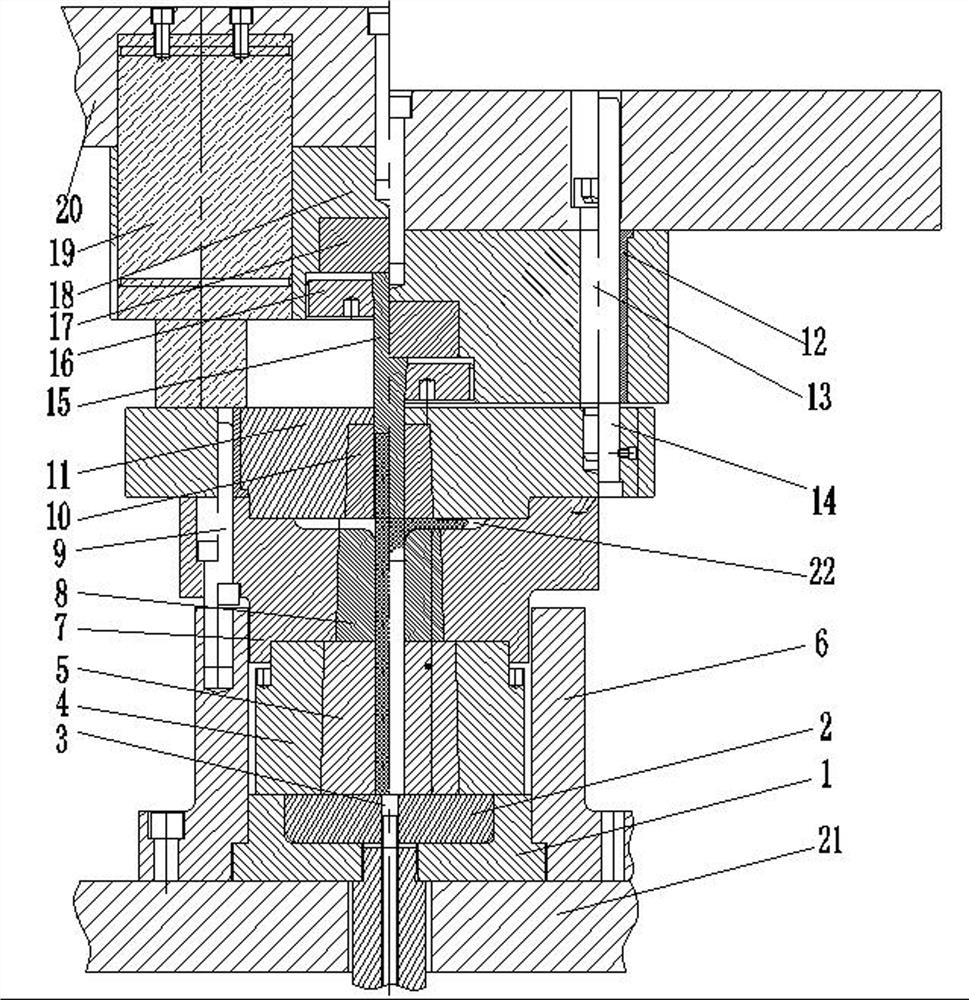

[0029] Step 1, such as figure 1 As shown in (a), according to the design length of the male shaft, the bar that has been spheroidized and annealed is sawed; after lubrication, the bar is put into figure 2 In the upsetting extrusion molding die shown, the hydraulic press presses down. First, the nitrogen spring 19 is pressed against the stress ring 11 of the lower die. When the hydraulic press continues to press down, the punch 15 in the upper die presses down the bar. At the upper end, the material flows radially to the cavity connected with the lower die hole to form a T-shaped head, which is obtained as follows figure 1 (b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com