Intelligent AGV warehousing robot

A technology of robots and robot bodies, which is applied to instruments, motor vehicles, computer parts, etc., can solve problems such as single function, labor waste, and low work efficiency, so as to improve storage efficiency, realize intelligence and informationization, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0027] As a preferred embodiment of the present invention, the power supply device 26 is connected to the control box 27 through wires, and the control box 27 includes an intelligent processor 28 and a control switch 29 .

[0028] As a preferred embodiment of the present invention, the intelligent processor 28 includes a circuit mainboard and a microprocessor and a processing chip arranged on the circuit mainboard, the microprocessor and the processing chip are connected by wires, and the intelligent processing The detector 28 is connected with the collection device 30 by wires.

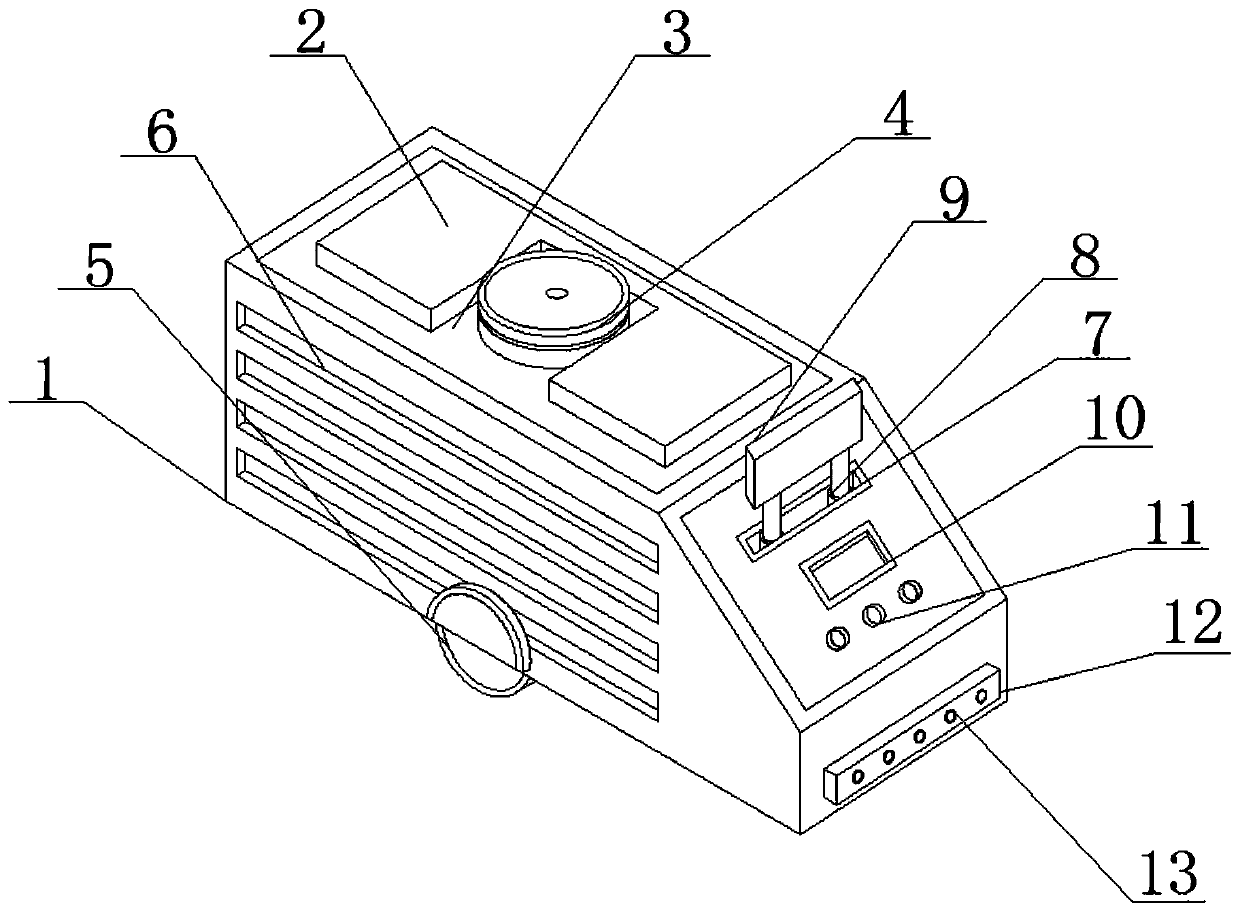

[0029] As a preferred embodiment of the present invention, one side of the box body 1 is provided with a cooling groove 6 .

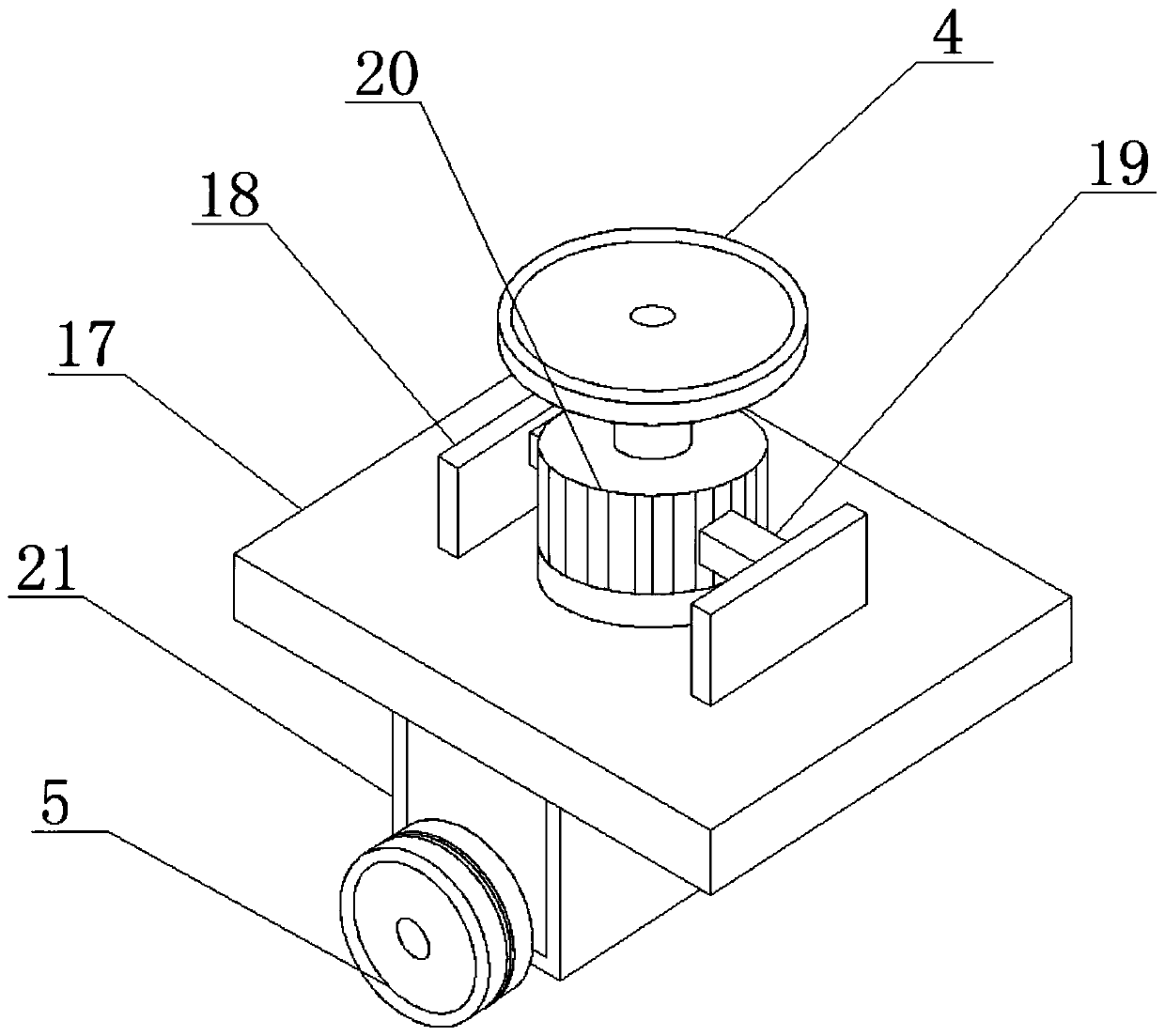

[0030] As a preferred embodiment of the present invention, the mounting plate 17 is installed on the bottom plate 22 , and the bottom plate 22 is provided with an opening one, and the opening one matches with the motor box 21 .

[0031] As a preferred embodiment of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com