An intelligent monitoring method for blast furnace skip top prevention

A technology of intelligent monitoring and feeding trucks, which is applied in elevators, transportation and packaging, elevators in buildings, etc., can solve problems such as derailment, inability to stop as required, and adverse effects of signal transmission of hoisting and dragging systems, etc., to achieve data Record and facilitate the analysis of the cause and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below with reference to the accompanying drawings.

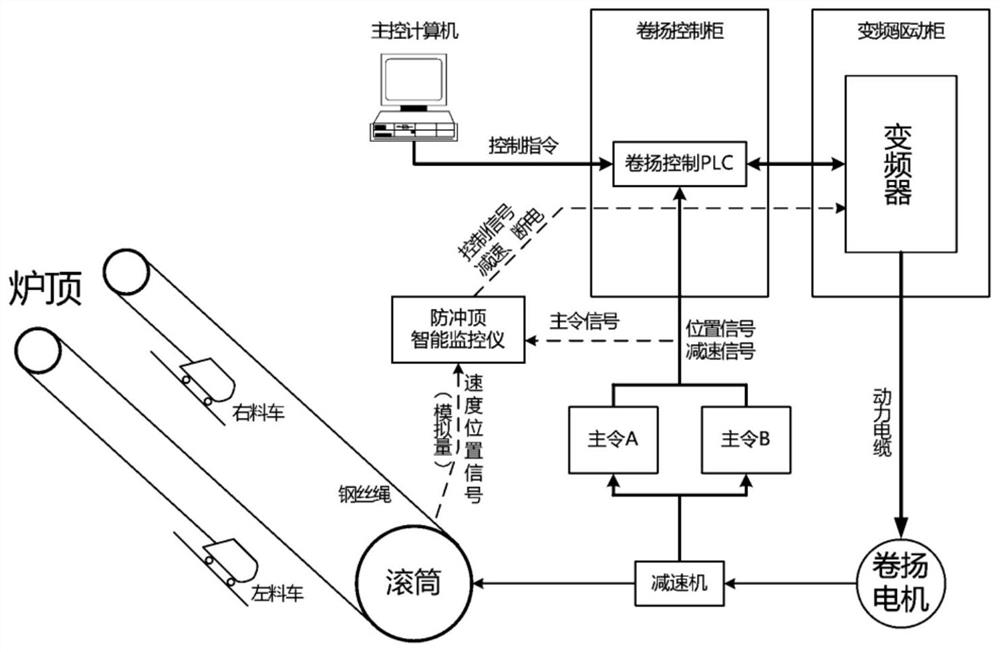

[0032] Anti furnace Car invention hoisting intelligent monitoring method, such as image 3 FIG achieved by the following steps:

[0033] Step 1: Access the drag winch controller system;

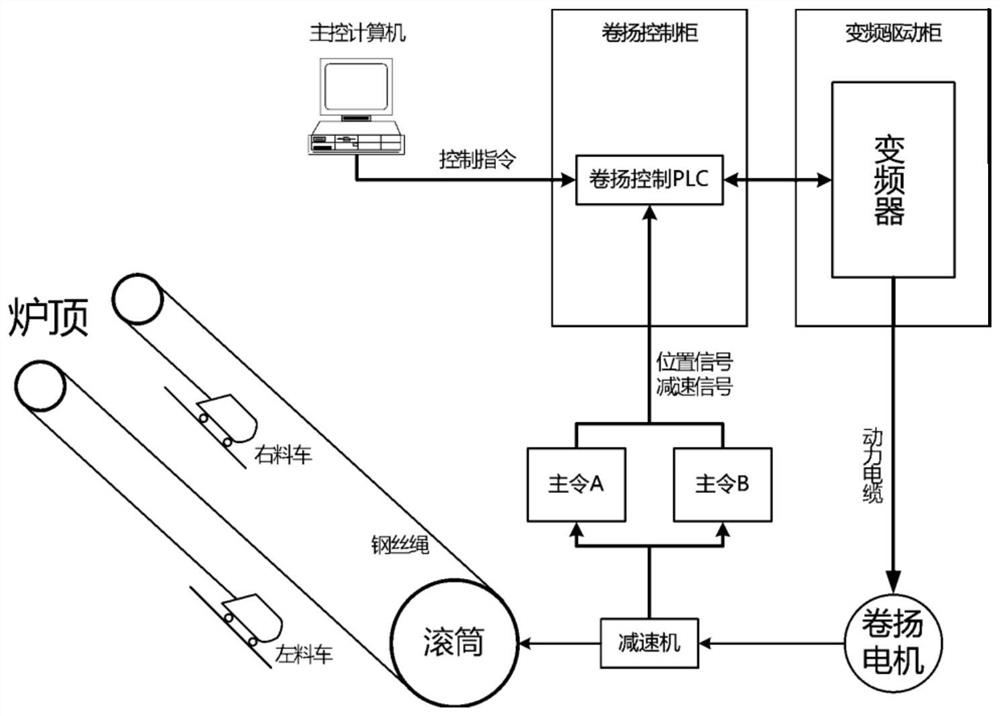

[0034] The controller PLC is a small core, the master A and the output B of the master positions (switch) access controller, two output signals (and switch) all the way to access the drive controller (for controlling the speed ), the total power inverter further access path (for controlling the opening power-off), as Figure 4 Indicated.

[0035] Step 2: determining the filling time trolley BF - correspondence relationship between the rotational speed of the drum;

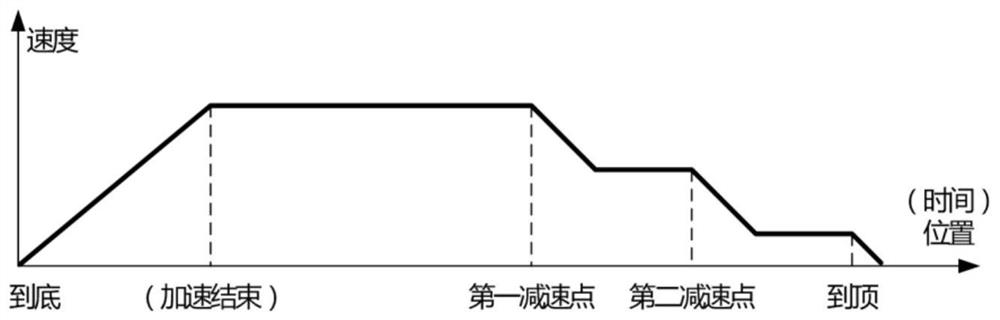

[0036] Since the materials blast furnace car running the curve, a fixed curve, the vehicle starts running from the base material, to the end of acceleration, then deceleration point first, second deceleration time point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com