Push shovel-type salt pan sea salt collecting device

A sea salt and salt field technology, applied in transportation and packaging, energy input, motor vehicles, etc., can solve the problems of low work efficiency, high labor intensity, and great effort to collect sea salt, so as to reduce labor intensity and improve work efficiency. , the effect of reducing the drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

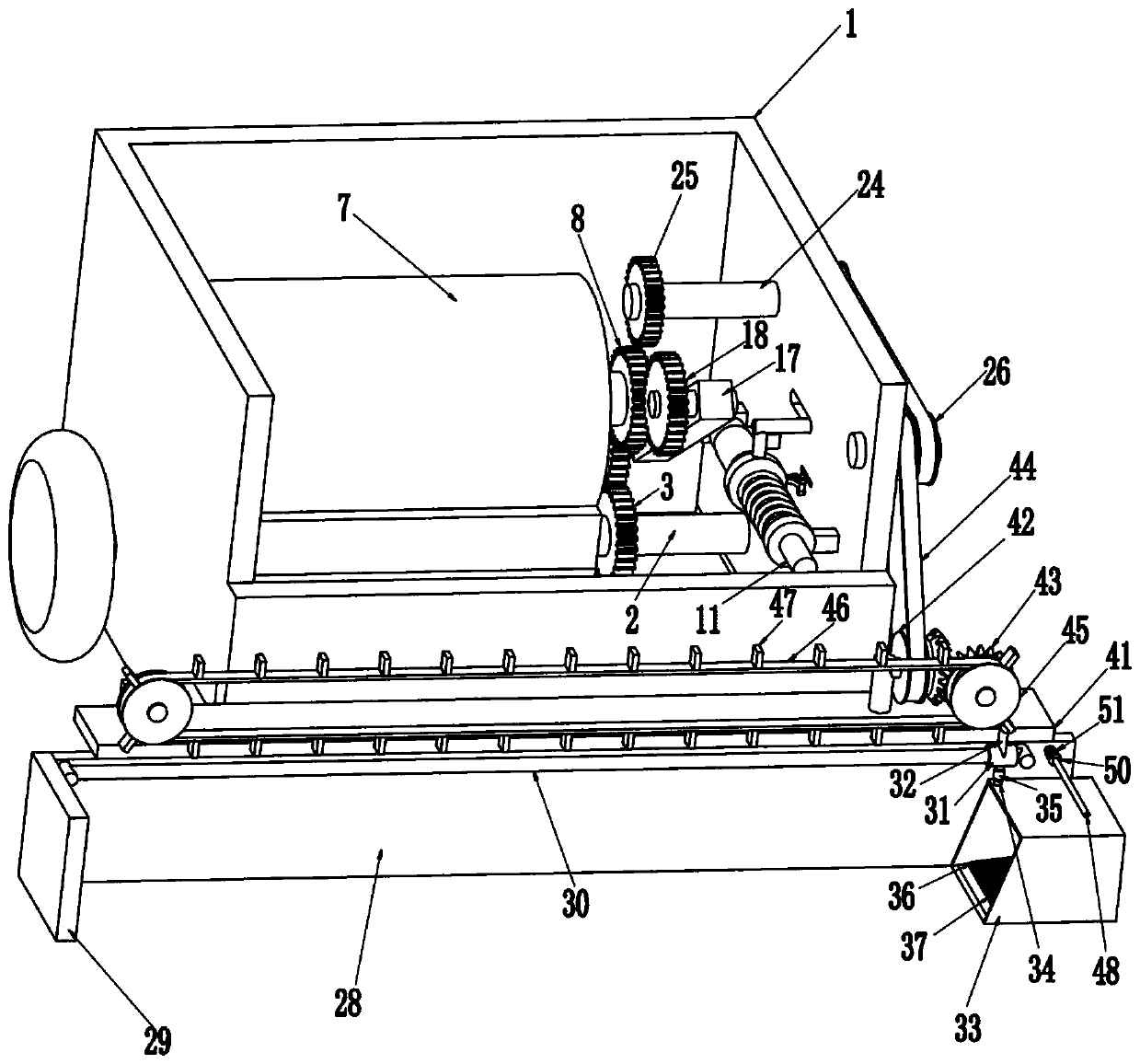

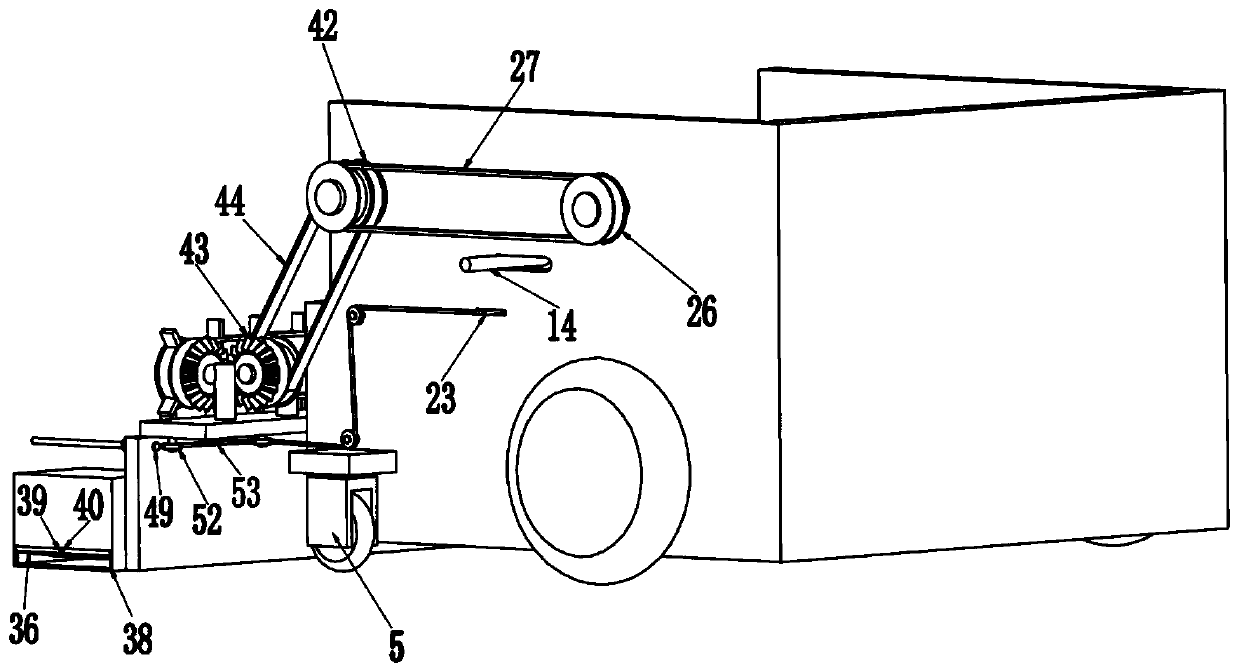

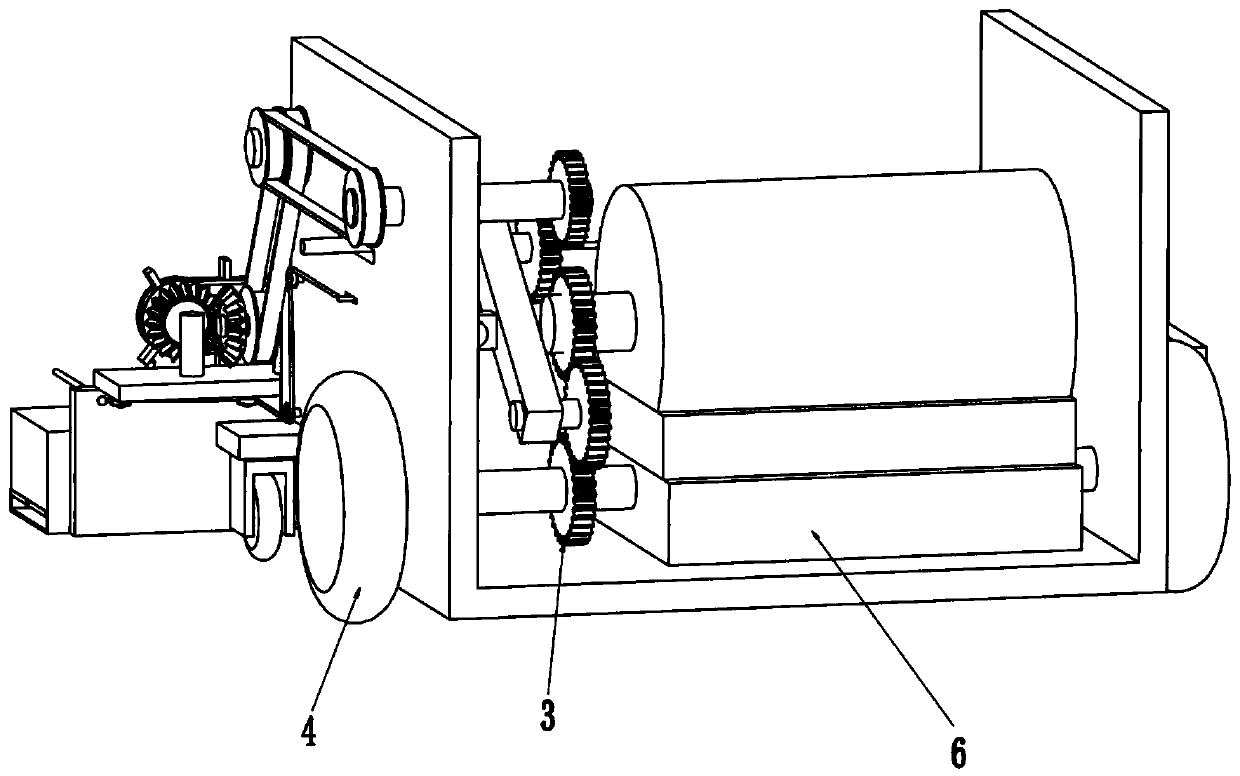

[0026] A device for collecting sea salt in push-and-shovel salt pans, such as Figure 1-6 As shown, it includes a housing 1, a first rotating rod 2, a roller 4, a universal wheel 5, a support block 6, a motor 7, a second gear 8, a first support sleeve 9, a second support sleeve 10, and a slide bar 11 , scraper 28, support plate 41, drive assembly, control assembly and collection assembly, the first rotating rod 2 is provided in the lower part of the rear side of the housing 1, and the first rotating rod 2 is provided with a driving assembly, which is used to drive The device moves, and the drive assembly can also be used to drive the collection assembly to work. The left and right ends of the first rotating rod 2 are provided with rollers 4, the lower part of the front side of the housing 1 is provided with a universal wheel 5, and the housing 1 is provided with a support block 6. The support block 6 is bolted with a motor 7, and the second gear 8 is installed on the output sh...

Embodiment 2

[0035] This example is on the basis of embodiment 1, as figure 1 , figure 2 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, it also includes a second push rod 48, a block 49, a fixed ring 50, a third spring 51, a guide wheel 52 and a stay cord 53, and the right part of the scraper 28 is slidably provided with a second push rod 48, and the second The rear end of the push rod 48 is provided with a stopper 49, the second push rod 48 is provided with a fixed ring 50, a third spring 51 is arranged between the fixed ring 50 and the scraper 28, and the bottom of the support plate 41 and the right universal wheel 5 Both the upper and the outer right wall of the housing 1 are provided with guide wheels 52 , and stay cords 53 are connected between the block 49 and the cross bar 23 , and the stay cords 53 bypass all the guide wheels 52 .

[0036] Also comprise guide rod 36, gauze 37, first ferrule 39 and pin 40, bucket 33 right side bottoms have drain outlet 38, be prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com