Thermally activated delayed fluorescent material and organic light-emitting diode prepared therefrom

A heat-activated delay and light-emitting diode technology, which is applied in luminescent materials, organic chemistry, chemical instruments and methods, etc., can solve the problems of lack of heat-activated delayed fluorescent materials, and achieve low singlet triplet energy level difference and high photoluminescence quantum production. efficiency, high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

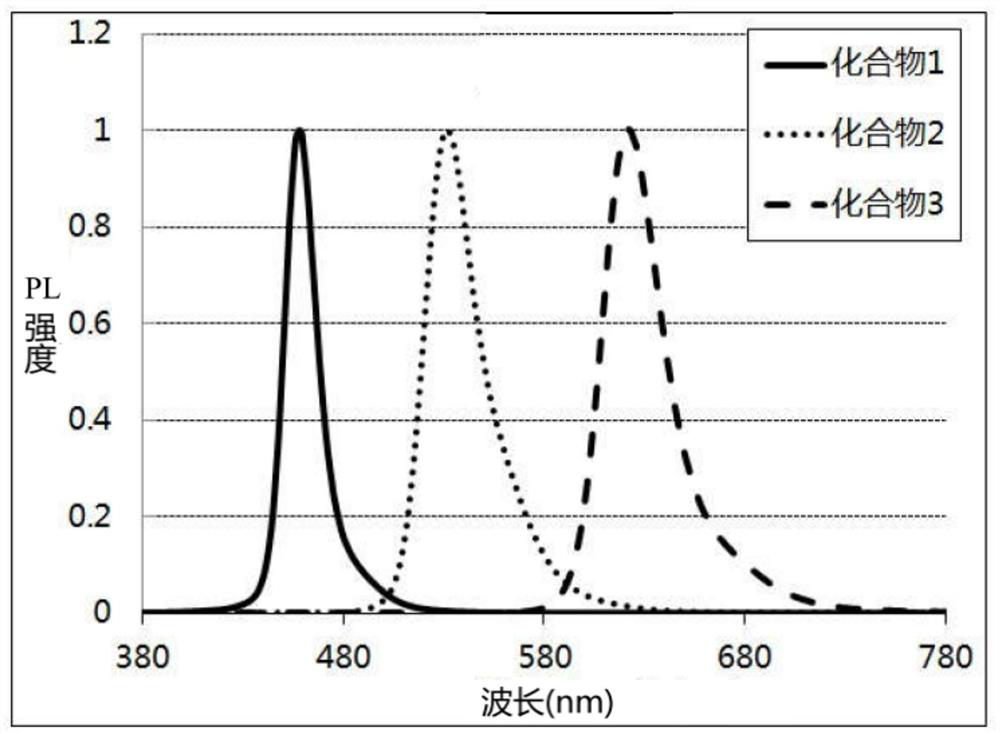

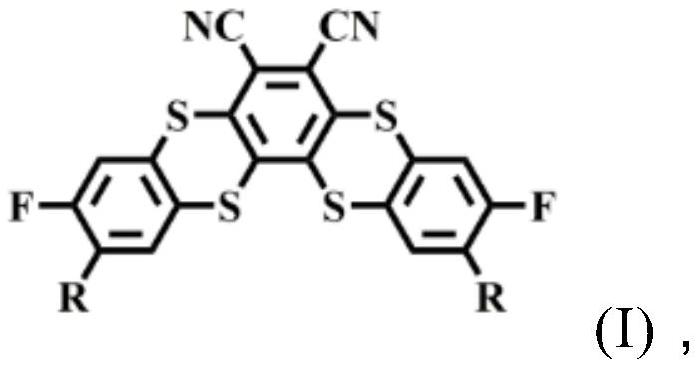

[0027] Example 1: Preparation of thermally activated delayed fluorescent material with the following structural formula

[0028]

[0029] The synthesis steps are as follows:

[0030]

[0031] First, add raw material 1 (3.0g, 5mmol), carbazole (2.0g, 12mmol), palladium acetate (90mg, 0.4mmol) and tri-tert-butylphosphine tetrafluoroborate (0.34g, 1.2 mmol). Then, put the two-necked bottle into the glove box, and add NaOt-Bu (1.16 g, 12 mmol) into the two-necked bottle. Next, under an argon atmosphere, pour 100 mL of toluene that had been dehydrated and deoxygenated into the two-neck flask, and react at 120° C. for 48 hours to obtain a reaction liquid. After cooling to room temperature, the reaction solution in the two-neck flask was poured into 300 mL of ice water. Subsequently, the reaction solution was extracted with dichloromethane. After three extractions, the organic phases obtained from each extraction were combined and separated and purified by column chromatogra...

Embodiment 2

[0032] Example 2: Preparation of thermally activated delayed fluorescent material with the following structural formula

[0033]

[0034] The synthesis steps are as follows:

[0035]

[0036] First, add raw material 1 (3.0g, 5mmol), 9,9-dimethylacridine (2.5g, 12mmol), palladium acetate (90mg, 0.4mmol) and tri-tert-butylphosphine tetrafluoroethylene to a 250mL two-necked flask Borate (0.34 g, 1.2 mmol). Then, put the two-necked bottle into the glove box, and add NaOt-Bu (1.16 g, 12 mmol) into the two-necked bottle. Next, under an argon atmosphere, pour 100 mL of toluene that had been dehydrated and deoxygenated into the two-neck flask, and react at 120° C. for 48 hours to obtain a reaction liquid. After cooling to room temperature, the reaction solution in the two-neck flask was poured into 300 mL of ice water. Subsequently, the reaction solution was extracted with dichloromethane. After three extractions, the organic phases obtained from each extraction were combined...

Embodiment 3

[0037] Example 3: Preparation of thermally activated delayed fluorescent material with the following structural formula

[0038]

[0039] The synthesis steps are as follows:

[0040]

[0041] First, add raw material 1 (3.0g, 5mmol), phenoxazine (2.2g, 12mmol), palladium acetate (90mg, 0.4mmol) and tri-tert-butylphosphine tetrafluoroborate (0.34g , 1.2 mmol). Then, put the two-necked bottle into the glove box, and add NaOt-Bu (1.16g, 12mmol) into the two-necked bottle. Next, under an argon atmosphere, pour 100 mL of toluene that had been dehydrated and deoxygenated into the two-neck flask, and react at 120° C. for 48 hours to obtain a reaction liquid. After cooling to room temperature, the reaction solution in the two-neck flask was poured into 300 mL of ice water. Subsequently, the reaction solution was extracted with dichloromethane, extracted three times, and the organic phases obtained by each extraction were combined, and separated and purified by column chromatog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com