A kind of fluorescent material and preparation method and application

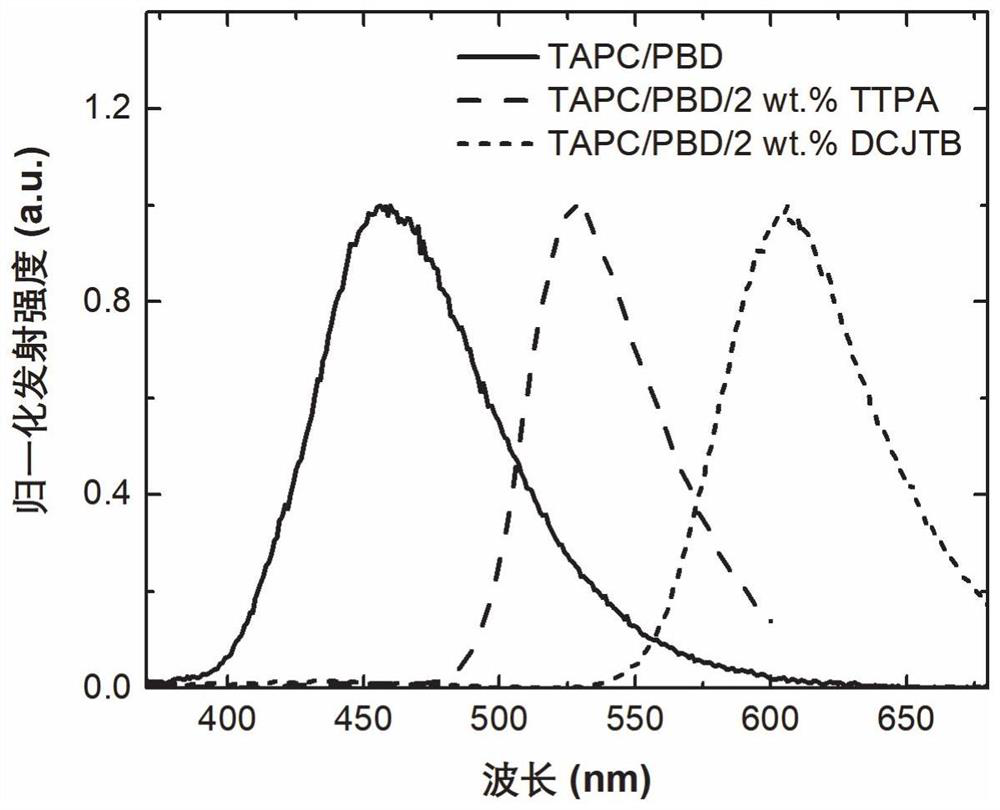

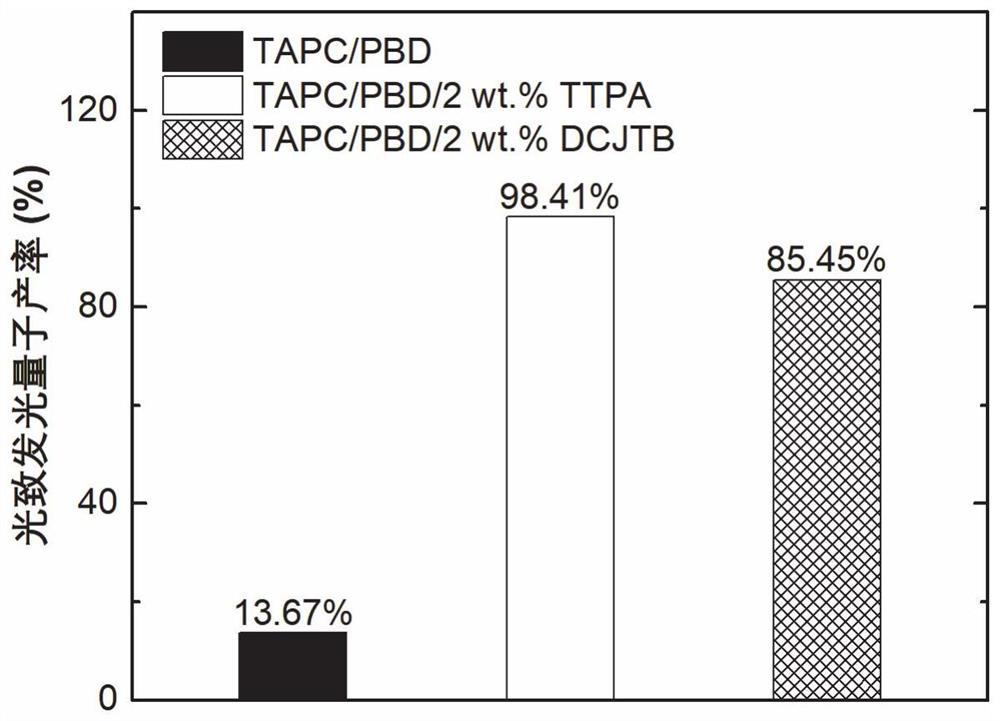

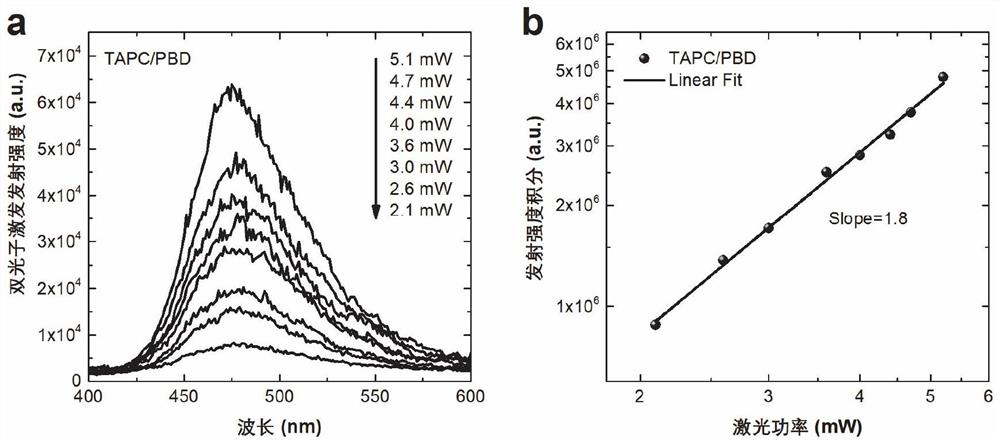

A technology of fluorescent materials and fluorescent dopants, applied in the fields of luminescent materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., can solve the saturation threshold and efficiency reduction of luminescence, the low efficiency of two-photon excitation fluorescence, and the attenuation of luminous efficiency and other problems, to achieve the effect of extremely high quantum yield of photoluminescence, remarkable two-photon properties, and high degree of overlap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In one or more embodiments of the present invention, a method for preparing a fluorescent material includes the following steps:

[0037] The donor material, the acceptor material, and the fluorescent dopant material are mixed and dissolved in a benign solvent, and stirred evenly at room temperature to obtain a clear solution; then the mixed drop is cast on the carrier, and the temperature is raised for annealing. The preparation method is simple and efficient, and a sample film with a larger thickness can be prepared.

[0038] The benign solvent is selected from acetonitrile, dimethyl sulfoxide, N,N-dimethylformamide or tetrahydrofuran solution; preferably, it is tetrahydrofuran. In tetrahydrofuran solution, it is beneficial to achieve high dispersion of different materials, and will not lead to the denaturation of the material itself, which is beneficial to promote the uniform and efficient doping of fluorescent dopants in exciplexes, and is beneficial to play host, ...

Embodiment 1

[0045] Preparation of exciplex material systems without fluorescent dopants:

[0046] The donor material (TAPC), acceptor material (PBD), and benign solvent (tetrahydrofuran) provided in this example were directly purchased from a reagent company.

[0047] The preparation method is as follows:

[0048] 1) Weigh 62.6 mg (0.1 mol) of TAPC and 35.4 mg (0.1 mol) of PBD, mix them and dissolve them together in 10 ml of tetrahydrofuran solvent, add magnets and place them on a magnetic stirring table to stir overnight to obtain a clear mixture;

[0049] 2) After stopping stirring, take a clean quartz piece and place it horizontally, and use a dropper to cast the mixed droplet on the quartz piece;

[0050] 3) Place the quartz plate bearing the sample on a hot stage and anneal at 50° C. for 20 minutes to obtain an undoped exciplex material film, which is marked as TAPC / PBD.

Embodiment 2

[0052] Preparation of green fluorescent dopant-doped exciplex material system:

[0053] The donor material (TAPC), acceptor material (PBD), green fluorescent dopant (TTPA), and benign solvent (tetrahydrofuran) provided in this example were directly purchased from a reagent company.

[0054] The preparation method is as follows:

[0055] 1) Weigh out 62.6 mg (0.1 mol) of TAPC, 35.4 mg (0.1 mol) of PBD, and 2.0 mg of TTPA, wherein by mass fraction, TTPA / (TAPC+PBD+TTPA)=2%, mix them together Dissolve in 10ml of tetrahydrofuran solvent, add magnetron, put it on a magnetic stirring table and stir overnight to obtain a clear mixed solution;

[0056] 2) After stopping stirring, take a clean quartz piece and place it horizontally, and use a dropper to cast the mixed droplet on the quartz piece;

[0057] 3) Place the quartz plate bearing the sample on a hot stage and anneal at 50° C. for 20 minutes to obtain an exciplex film doped with a green fluorescent agent, which is marked as TA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com