Production process of bis(trimethoxysilyl)ethane product

A trimethoxysilyl-based and production technology technology, applied in the field of production technology of diethane products, can solve problems such as difficulty in meeting production and life, difficulty in realizing industrialized production in production technology, low product purity, etc., and achieves easy operation and preparation. The effect of increasing the rate of reaction and the high reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

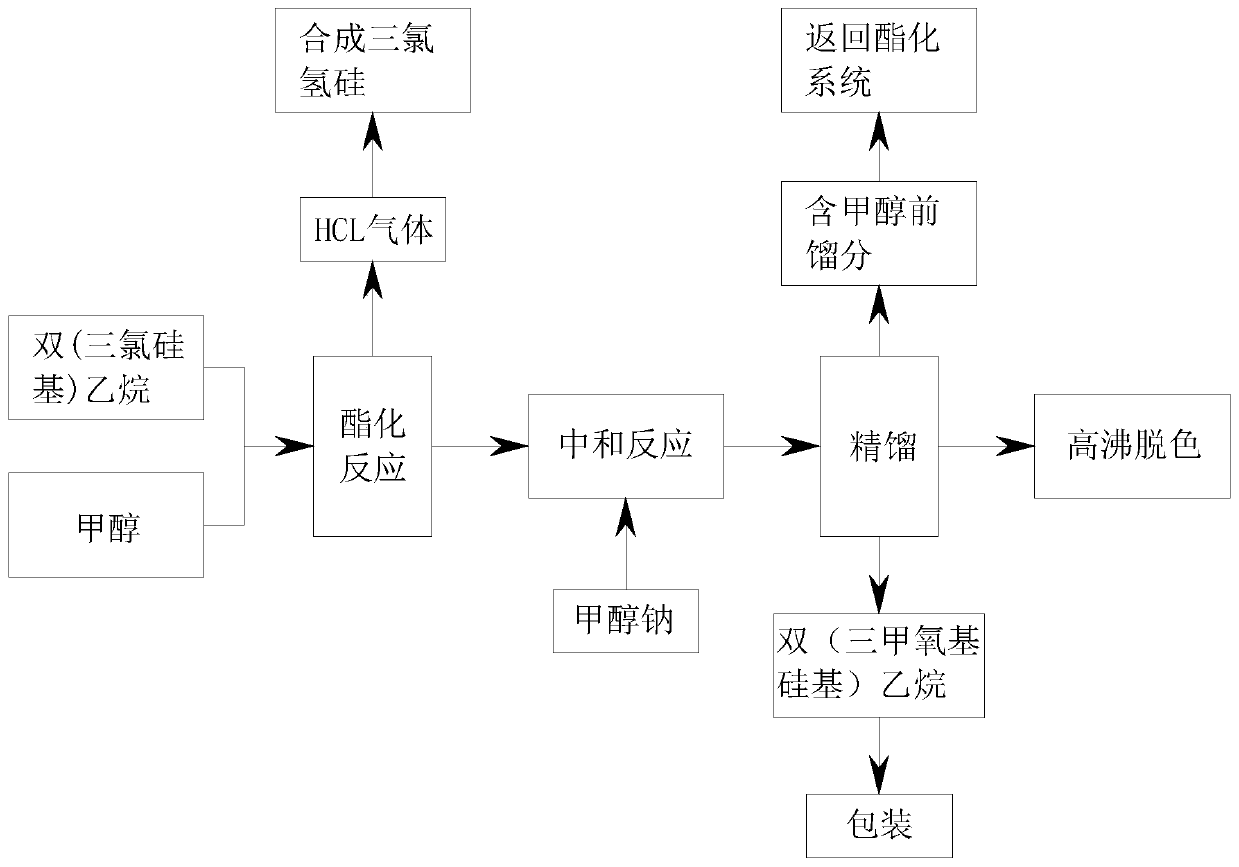

[0026] A kind of production technique of two (trimethoxysilyl) ethane products, production technique comprises the following steps:

[0027] S1: Preheat the methanol, and the preheated methanol is esterified with the bis(trichlorosilyl)ethane purified by rectification to generate crude bis(trimethoxysilyl)ethane, HCL gas and a small amount Hydrolyzed polymer;

[0028] S2: After the crude product bis(trimethoxysilyl)ethane and a small amount of hydrolyzed polymer are neutralized by sodium methoxide, they are placed in the crude product tank;

[0029] S3: Use a transfer pump to pump the neutralized crude material into the vacuum rectification tower for separation. The front fraction is extracted from the top of the tower, and bis(trimethoxysilyl)ethane is extracted from the bottom material, and the by-product is high boiling. The material is decolorized through a decolorizing tank;

[0030] S4: packing the bis(trimethoxysilyl)ethane to obtain the finished product.

[0031] Fu...

Embodiment 2

[0039] A kind of production technology of two (trimethoxysilyl) ethane products, production technology comprises the following steps:

[0040] S1: Carry out esterification reaction between methanol and distilled and purified bis(trichlorosilyl)ethane to generate crude bis(trimethoxysilyl)ethane, HCL gas and a small amount of hydrolyzed polymer;

[0041] S2: After the crude product bis(trimethoxysilyl)ethane and a small amount of hydrolyzed polymer are neutralized by sodium methoxide, they are placed in the crude product tank;

[0042] S3: Use a transfer pump to pump the neutralized crude material into the vacuum rectification tower for separation. The front fraction is extracted from the top of the tower, and bis(trimethoxysilyl)ethane is extracted from the bottom material, and the by-product is high boiling. The material is decolorized through a decolorizing tank;

[0043] S4: packing the bis(trimethoxysilyl)ethane to obtain the finished product.

[0044] Further, the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com