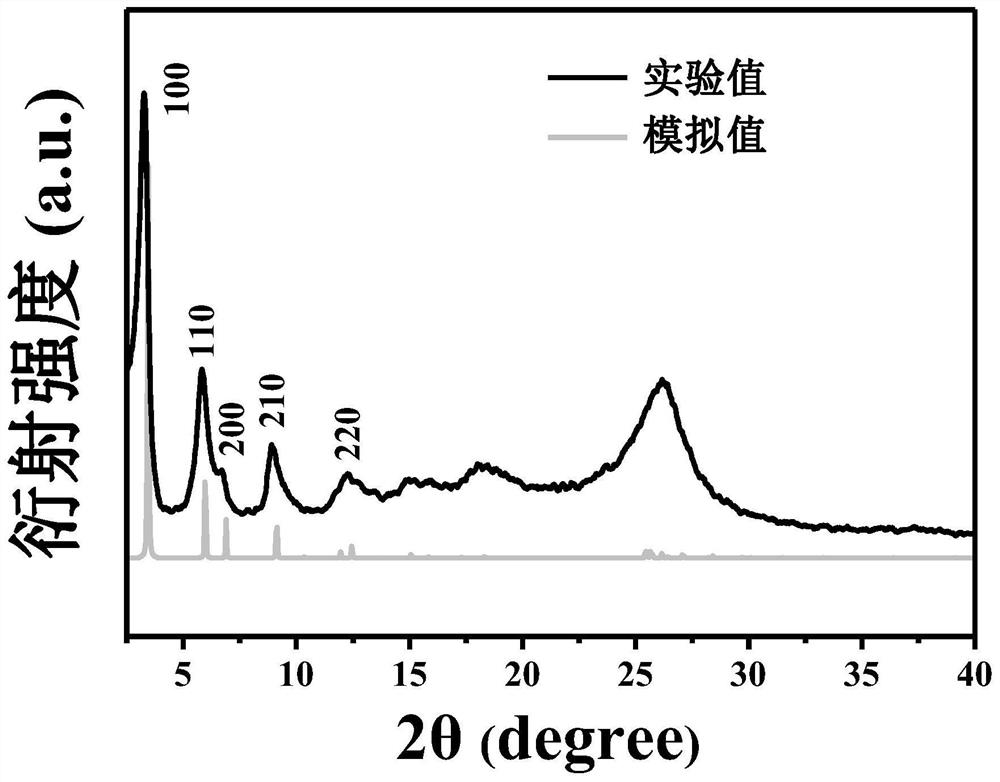

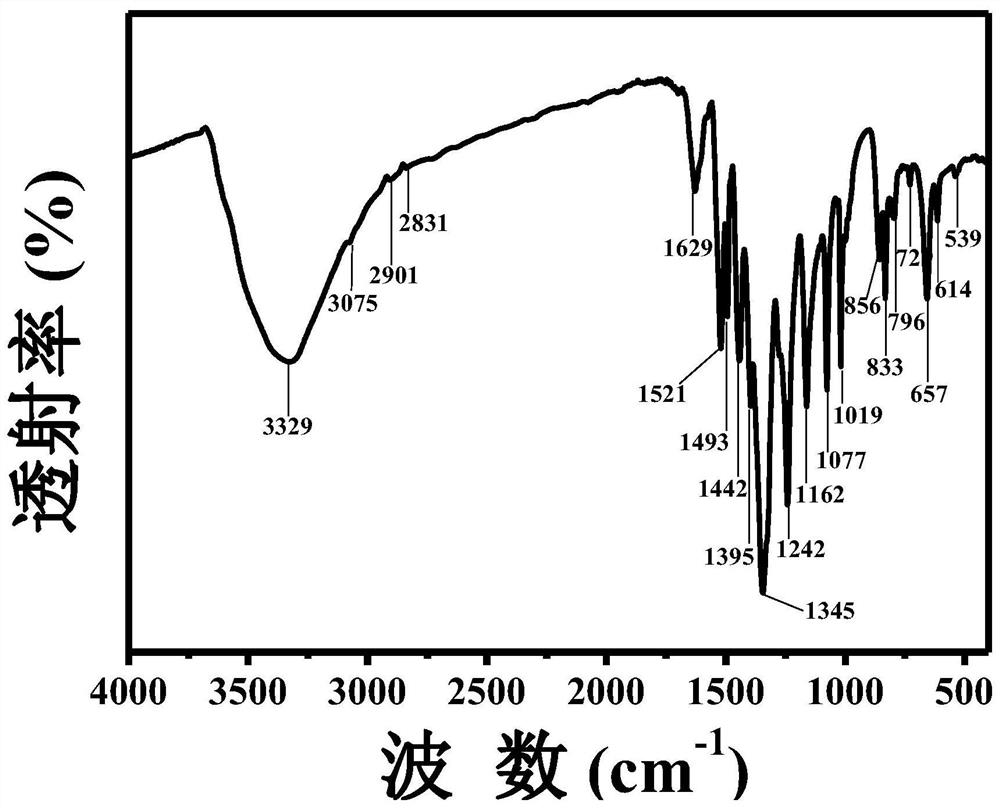

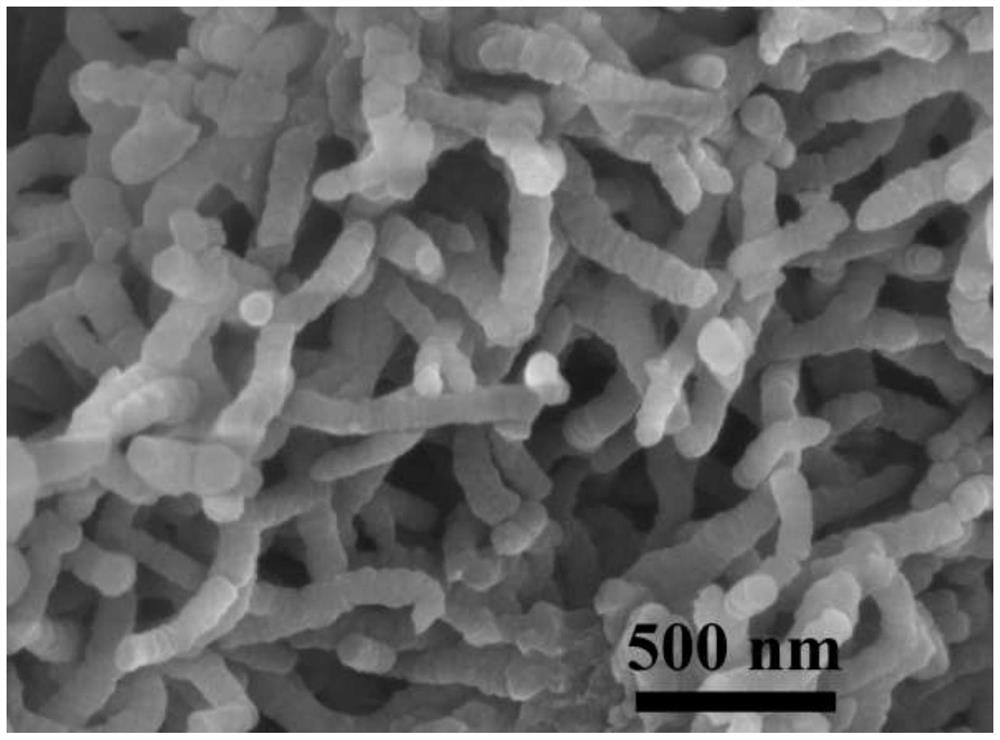

Cof-5 one-dimensional rod-shaped crystal material and preparation method thereof

A COF-5, 1.COF-5 technology, applied in the field of porous materials, can solve the problems of inhomogeneity, irregular crystal morphology and small size of COF-5, and achieve regular morphology, improved morphology and good growth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the COF-5 one-dimensional rod-shaped crystal material provided in the first embodiment includes the following steps:

[0028] (1) In the glove box, mix 2,3,6,7,10,11-hexahydroxytriphenyl, 1,4-benzenediboronic acid, 1,3,5-trimethylbenzene, 1,4-dioxahexa The ring is mixed in the ratio of 0.1mmol:0.1mmol:12.5mL:12.5mL;

[0029] (2) Seal the mixture, oscillate after ultrasonic dispersion, and obtain a uniform dispersion;

[0030] (3) Heat the dispersion to 85°C and react for 72 hours;

[0031] (4) The reaction product was washed with acetone, dried in vacuum, and finally argon protective gas was passed through, and the product was heat-treated at 200° C. for 1 hour to obtain the COF-5 one-dimensional rod-shaped crystal material.

Embodiment 2

[0033] The preparation method of the COF-5 one-dimensional rod-shaped crystal material provided in Example 2 includes the following steps:

[0034] (1) In the glove box, mix 2,3,6,7,10,11-hexahydroxytriphenyl, 1,4-benzenediboronic acid, 1,3,5-trimethylbenzene, 1,4-dioxahexa The ring is mixed in the ratio of 0.2mmol:0.3mmol:12mL:13mL;

[0035] (2) Seal the mixture, oscillate after ultrasonic dispersion, and obtain a uniform dispersion;

[0036] (3) Heat the dispersion to 100°C and react for 84 hours;

[0037] (4) The reaction product was washed with acetone, dried in vacuum, and finally argon protective gas was passed through, and the product was heat-treated at 220° C. for 1 hour to obtain the COF-5 one-dimensional rod-shaped crystal material.

Embodiment 3

[0039] The preparation method of the COF-5 one-dimensional rod-shaped crystal material provided in Example 3 includes the following steps:

[0040] (1) In the glove box, mix 2,3,6,7,10,11-hexahydroxytriphenyl, 1,4-benzenediboronic acid, 1,3,5-trimethylbenzene, 1,4-dioxahexa The ring is mixed in the ratio of 0.3mmol:0.5mmol:10mL:15mL;

[0041] (2) Seal the mixture, oscillate after ultrasonic dispersion, and obtain a uniform dispersion;

[0042] (3) Heat the dispersion to 80°C and react for 96 hours;

[0043] (4) The reaction product was washed with acetone, dried in vacuum, and finally argon protective gas was passed through, and the product was heat-treated at 250° C. for 2 hours to obtain the COF-5 one-dimensional rod-shaped crystal material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com